Method for measuring carbon content in high-carbon ferrochrome by infrared absorption method

An infrared absorption, high-carbon ferrochrome technology, applied in the field of chemical analysis, can solve problems such as the lack of ideal flux ratio, achieve the effects of stabilizing carbon analysis results, reducing carbon release speed, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

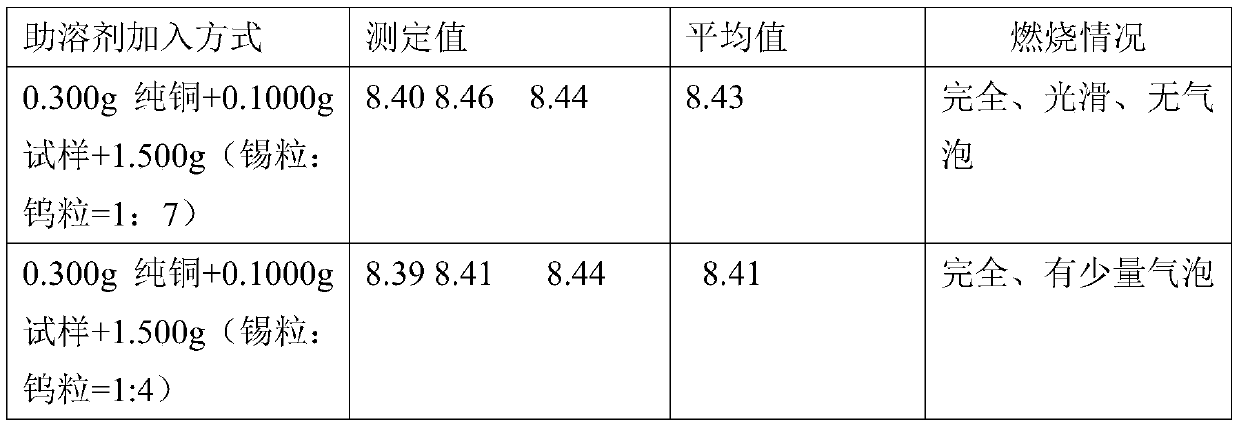

[0040] Weigh YSBC37648-10 high-carbon ferrochrome standard samples of different masses with an electronic balance, accurate to 0.1mg, place them in a pre-weighed pure copper carbon-sulfur ceramic crucible of 0.300g±0.005g on the balance, mix well, and then cover Tin: tungsten = 1: 7 mixed flux 1.500g±0.005g, shake the crucible gently, then place the carbon-sulfur ceramic crucible on a high-frequency infrared carbon-sulfur meter to measure the carbon content, operate according to the instrument manual, parallel Determination of YSBC37648-10 high-carbon ferrochrome standard sample twice, the measurement results are shown in Table 1

[0041] Table 1

[0042] Sample weight / g Measurements% 0.0500 8.35 8.30 0.0800 8.42 8.41 0.1000 8.47 8.45 0.0120 8.40 8.44 0.0140 8.24 8.20 0.0150 8.30 8.26

[0043] Note: The analysis sample is YSBC37648-10 high-carbon ferrochromium C% is 8.49% The difference is 0.20

[0044] It can be inferred from T...

Embodiment 2

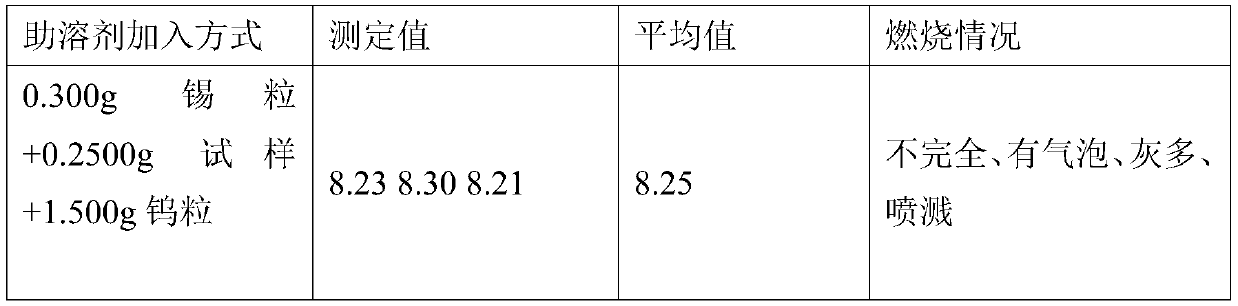

[0046] Weigh 0.2500g YSBC37648-10 high-carbon ferrochromium standard sample with an electronic balance, accurate to 0.1mg, place it in a crucible containing 0.300g±0.005g tin particles in advance, cover 1.500g±0.005g tungsten particles, the ratio of tin to tungsten is 1 : 5. Gently shake the crucible, then place the carbon-sulfur ceramic crucible on a high-frequency infrared carbon-sulfur meter to measure the carbon content, operate according to the instrument manual, and measure the YSBC37648-10 high-carbon ferrochrome standard sample 3 times in parallel. The measurement results are shown in Table 2.

[0047] Table 2

[0048]

[0049] Note: The analysis sample is YSBC37648-10 high-carbon ferrochromium C% is 8.49% The difference is 0.20.

[0050] It can be seen from Table 2 that: according to GB / T 4699.4-2008 "Determination of Carbon Content in Ferrochromium and Silicon-Chromium Alloys by Infrared Absorption Method and Gravimetric Method", the infrared absorption method i...

Embodiment 3

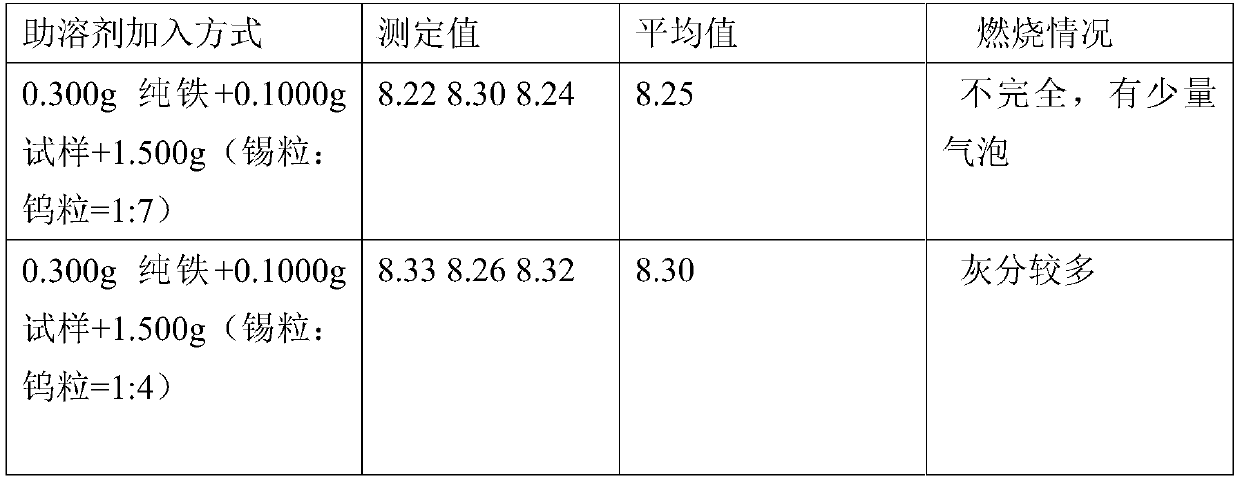

[0052] Weigh 0.1000g YSBC37648-10 high-carbon ferrochromium standard sample with an electronic balance, accurate to 0.1mg, place it in a pre-accurately weighed 0.300g±0.005g pure iron carbon-sulfur ceramic crucible on the balance, mix well, and then cover tin respectively : Tungsten = 1: 7, tin: tungsten = 1: 4 mixed flux 1.500g ± 0.005g, shake the crucible gently, and then place the carbon-sulfur ceramic crucible on a high-frequency infrared carbon-sulfur analyzer to measure the carbon content. Operate in accordance with the instrument manual, and measure YSBC37648-10 high-carbon ferrochrome standard sample in parallel for 3 times. See Table 3 for co-solvent addition methods and combustion conditions

[0053] table 3

[0054]

[0055] Note: The analysis sample is YSBC37648-10 high-carbon ferrochromium C% is 8.49% The difference is 0.20.

[0056] It can be seen from Table 3: According to the analysis in this way, the carbon content in high-carbon ferrochrome is measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com