Method for preparing lithium metal battery negative electrode supported by carbon/tin composite substrate

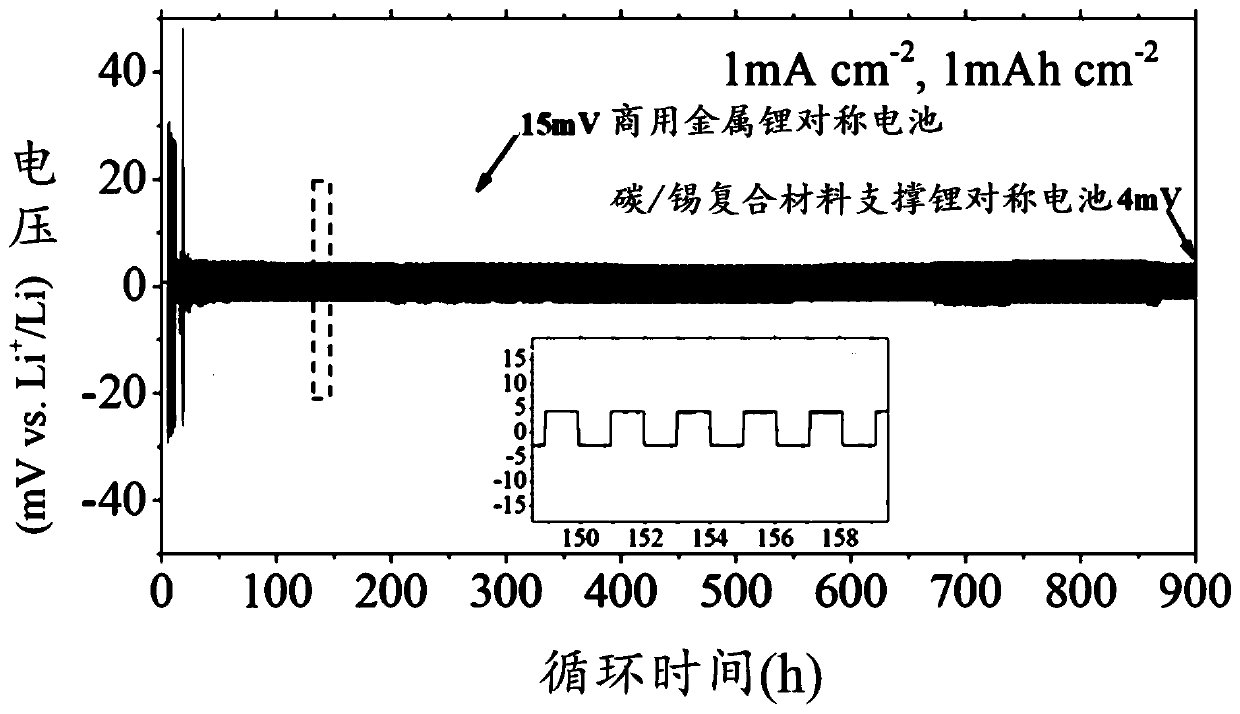

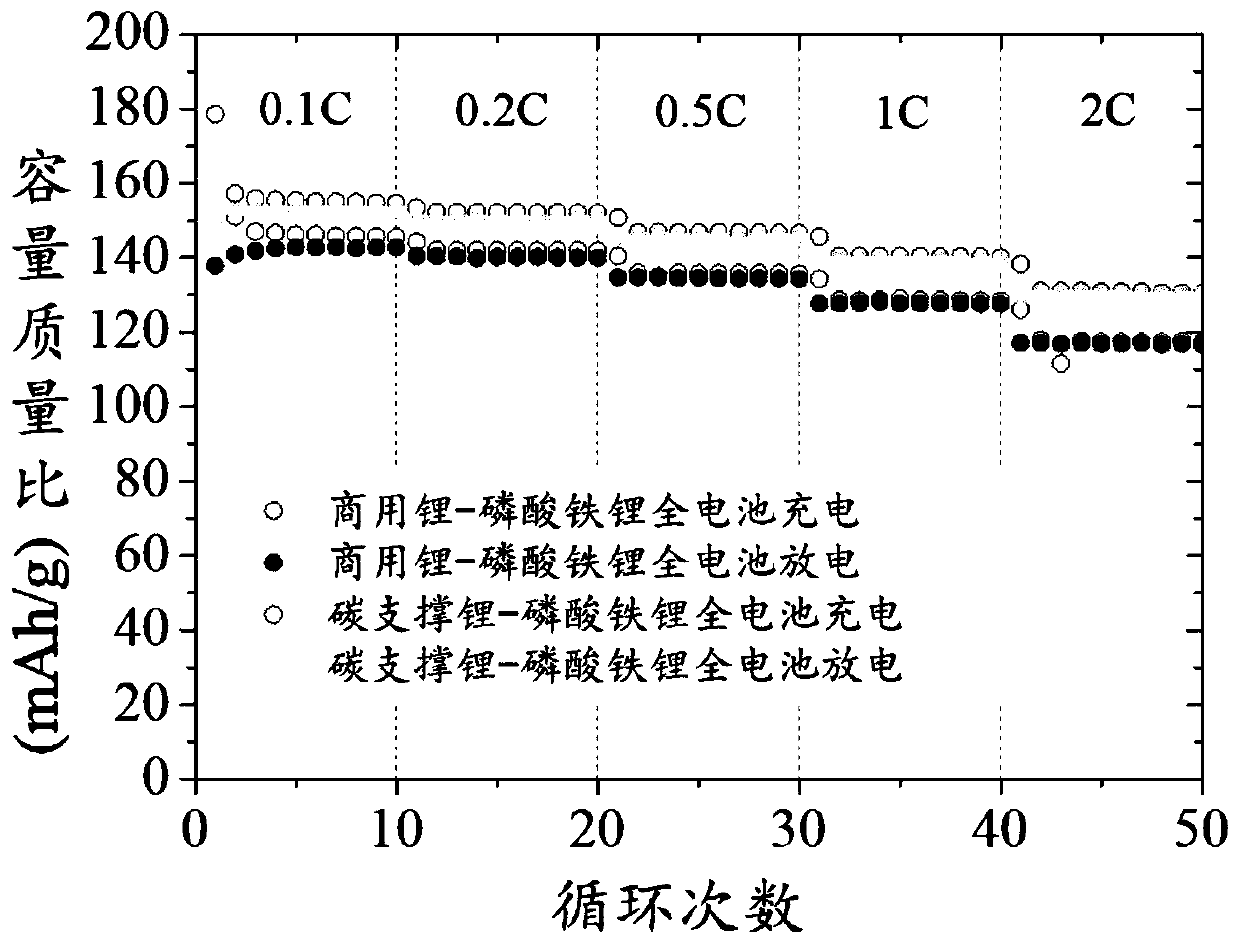

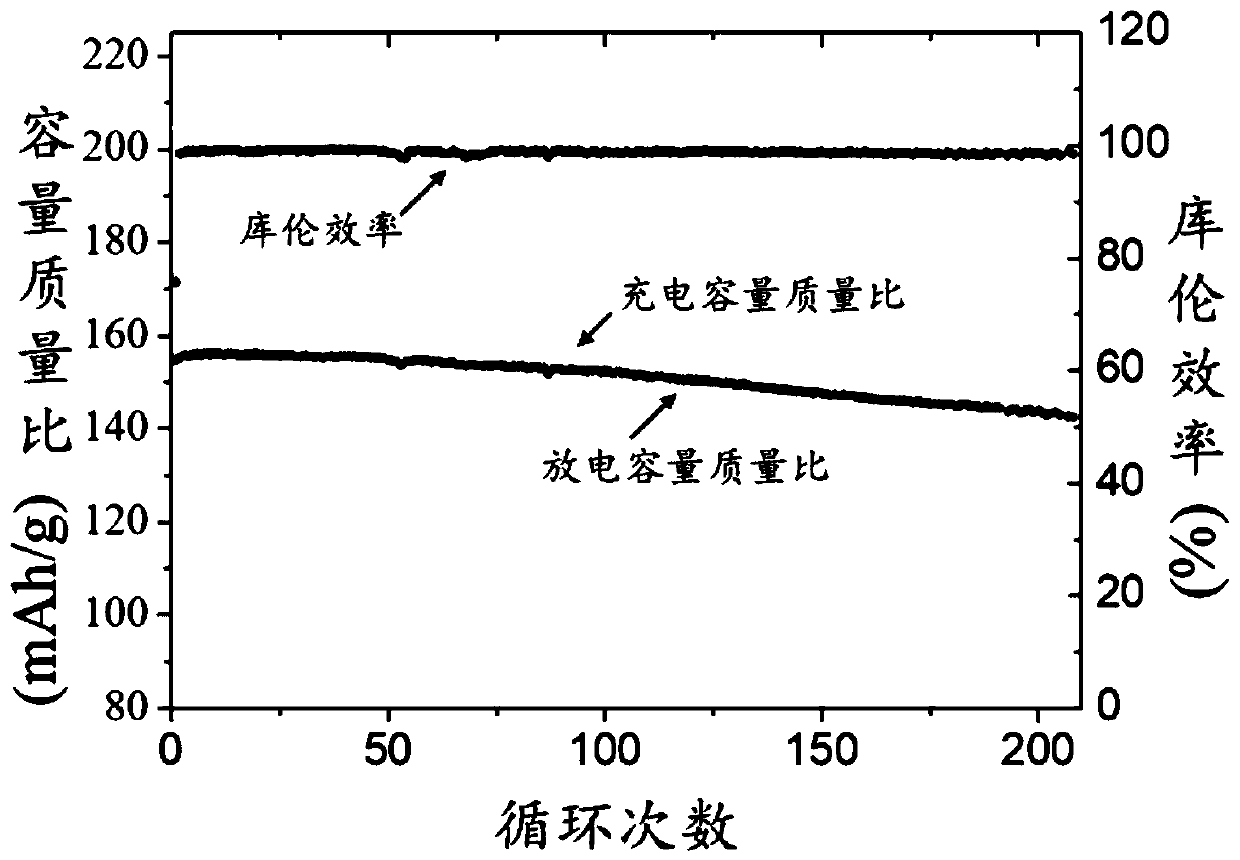

A technology for lithium metal batteries and composite substrates, which is applied in electrode manufacturing, battery electrodes, lithium batteries, etc., can solve problems such as the inability to solve lithium volume changes, and achieve inhibiting the formation of dendrites, high specific surface area, and good lithophilicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment includes the following steps:

[0022] Step 1: Weigh 0.108g of potassium stannate and 0.675g of urea in a mixed solution of 15mL of water and 15mL of ethanol. After stirring evenly, add the solution into the hydrothermal reaction kettle, and then add 3 pieces of commercial Carbon cloth, heated at 180°C for 18 hours, after the reaction, the product was washed 3 times with deionized water and dried;

[0023] The second step: calcinate the product obtained in the first step at 600 ° C for 2 hours in an inert atmosphere furnace, and the heating rate is 5 ° C min -1 , the reaction is completed, after the obtained carbon / tin composite support material is cooled to normal temperature, the product is transferred to a vacuum environment;

[0024] Step 3: Melt the commercial lithium sheet at 300°C under vacuum conditions, and then soak the composite support material in the molten lithium metal to complete the loading. The obtained product is the negative electrod...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] Step 1: Weigh 0.216g of potassium stannate and 1.675g of urea in a mixed solution of 20mL of water and 20mL of ethanol. After stirring evenly, add the solution into the hydrothermal reaction kettle, and then add 3 pieces of commercial Carbon cloth, heated at 180°C for 24 hours, after the reaction, the product was washed 3 times with deionized water and dried;

[0029] The second step: calcinate the product obtained in the first step at 600 ° C for 2 hours in an inert atmosphere furnace, and the heating rate is 5 ° C min -1 , the reaction is completed, after the obtained carbon / tin composite support material is cooled to normal temperature, the product is transferred to a vacuum environment;

[0030] Step 3: Melt the commercial lithium sheet at 300°C under vacuum conditions, and then soak the composite support material in the molten lithium metal to complete the loading. The obtained product is the negative electrod...

Embodiment 3

[0033] This embodiment includes the following steps:

[0034] Step 1: Weigh 0.5g of potassium stannate and 3g of urea in a mixed solution of 40mL of water and 40mL of ethanol. After stirring evenly, add the solution into the hydrothermal reaction kettle, and then add 4 pieces of commercial carbon with a diameter of 10mm. cloth, heated at 240°C for 24 hours, after the reaction, the product was washed 5 times with deionized water and dried;

[0035] The second step: calcinate the product obtained in the first step at 600 ° C for 2 hours in an inert atmosphere furnace, and the heating rate is 5 ° C min -1 , the reaction is completed, after the obtained carbon / tin composite support material is cooled to normal temperature, the product is transferred to a vacuum environment;

[0036] Step 3: Melt the commercial lithium sheet at 350°C under vacuum conditions, and then infiltrate the composite support material in the molten lithium metal to complete the loading. The resulting produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com