Lithium battery negative electrode and lithium battery

A lithium battery and negative electrode technology, applied in the field of lithium battery negative electrode and lithium battery, can solve problems such as hidden dangers of battery safety performance, low theoretical capacity of graphite negative electrode, battery capacity attenuation, etc., so as to improve safety performance and cycle performance, and improve lithophilicity. , the effect of avoided losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

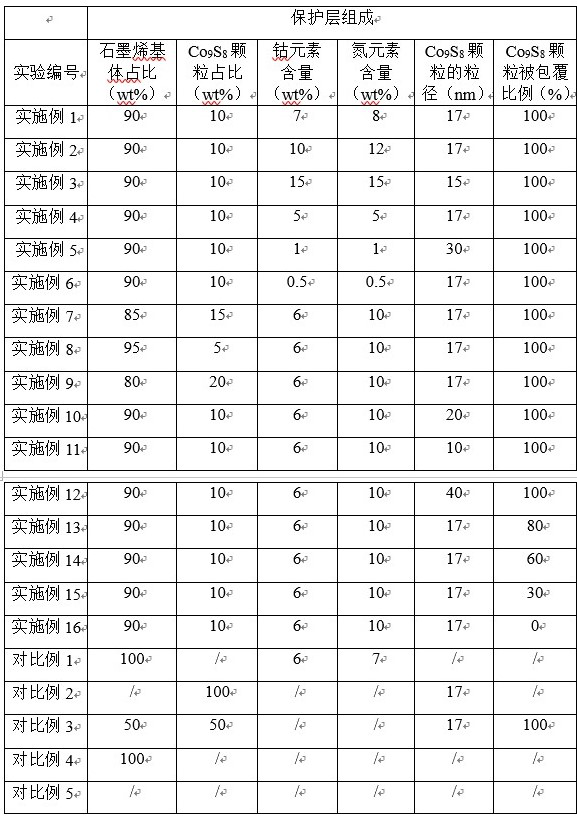

Examples

preparation example Construction

[0034] There is no mandatory requirement for the preparation method of the negative electrode of the lithium battery. The negative electrode of the lithium battery can be obtained by coating the protective layer slurry on the surface of the negative electrode current collector; it can also be coated with the negative electrode active material slurry and the protective layer slurry on the surface of the negative electrode current collector in sequence. Material, obtain lithium battery negative electrode.

[0035] Wherein, the preparation of protective layer slurry comprises the following steps:

[0036] (1) Dissolving the cobalt source, nitrogen source, and transition metal source in a solvent, stirring to react to obtain a reaction liquid;

[0037] (2) After treating the carbon source in acid, add it to the reaction solution in step (1), stir and evaporate to obtain a black powder;

[0038] (3) Calcining the black powder obtained in step (2) at high temperature under an inert...

Embodiment 1

[0049] (1) Mix 0.75ml of aniline, 218g of Co(NO 3 ) 2 ﹒ 6H 2 O, 1.25g (NH 4 ) 2 S 2 o 8 Add to 125ml of 1M hydrochloric acid solution, stir and react to obtain a reaction solution;

[0050] (2) Pretreat 0.1g of carbon black in 70% nitric acid and disperse it in 10ml of 1M hydrochloric acid solution, then add it to the reaction solution obtained in step (1), stir for 48 hours, and then Stir and evaporate the solution on a heating plate at ℃ to obtain a black powder, which is ground with a mortar;

[0051] (3) The powder obtained in step (2) was calcined and carbonized in a tube furnace at a high temperature of 800°C for one hour under an argon atmosphere, and the calcined powder was heated in 0.5M H 2 SO 4 Pickling in the solution at 80-90°C for 8 hours, and then drying in a vacuum oven for 12 hours at 100°C. Then, after secondary calcination in a tube furnace, a composite material is obtained. The composite material is a graphene matrix co-doped with cobalt and nitr...

Embodiment 2

[0054] The difference from Example 1 is that the high-temperature calcination temperature in step (3) is 750°C; the obtained composite material is a graphene matrix co-doped with cobalt and nitrogen elements and a Co 9 S 8 Particles, wherein, in the graphene matrix, the mass content of cobalt element is 10%, the mass content of nitrogen element is 12%, in the composite material, the mass proportion of graphene matrix is 90%, Co 9 S 8 The mass proportion of particles is 10%, and the Co 9 S 8 The particle diameter of the particles was 17 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com