A cobalt-nickel bimetallic nitrogen-doped carbon composite containing single-atom active sites

An active site, nitrogen-doped carbon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of few metal nitrogen carbon materials and the adjustment effect of surface metal doping is not considered, and meet the equipment requirements Low, improve the electrochemical performance, the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

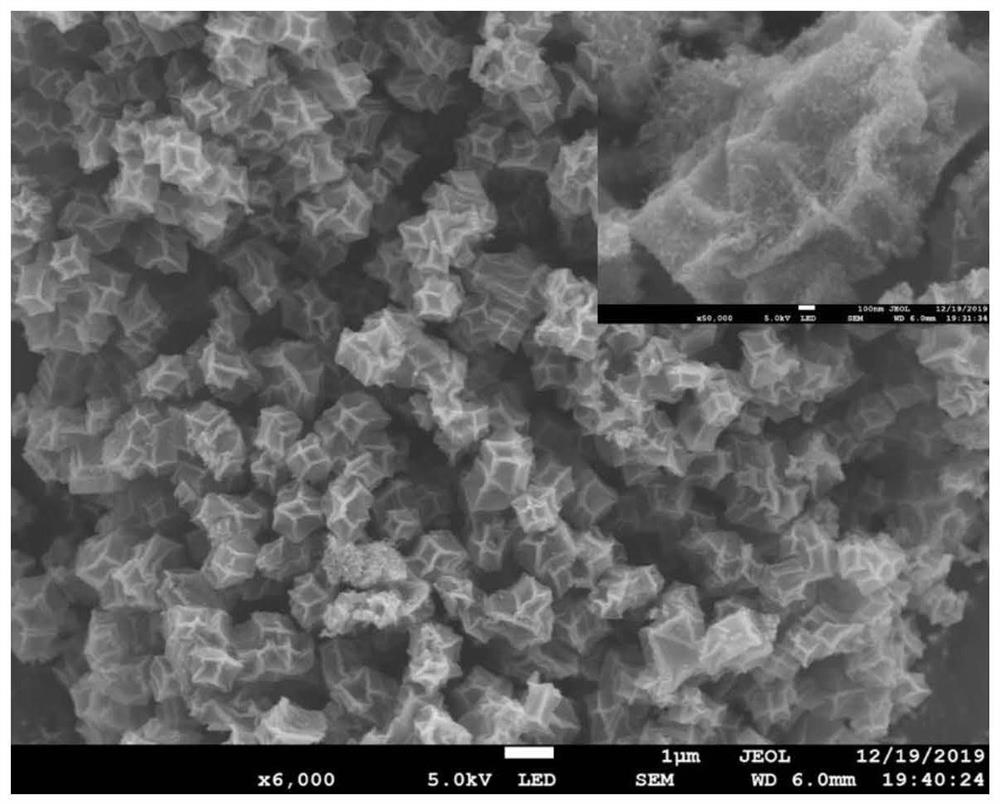

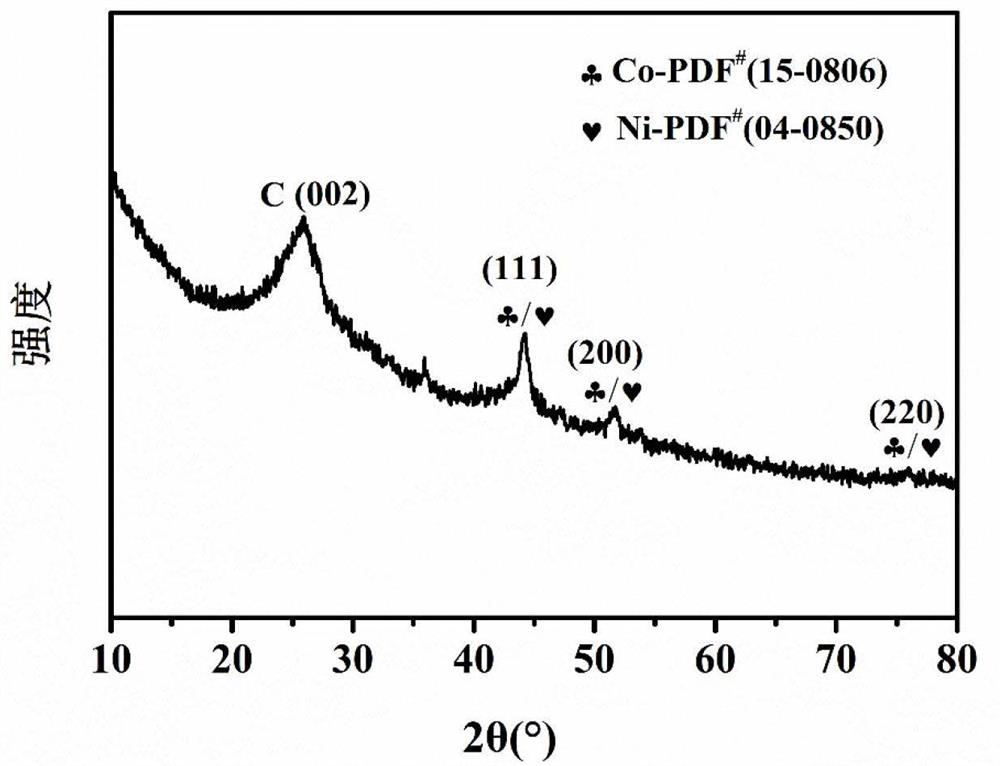

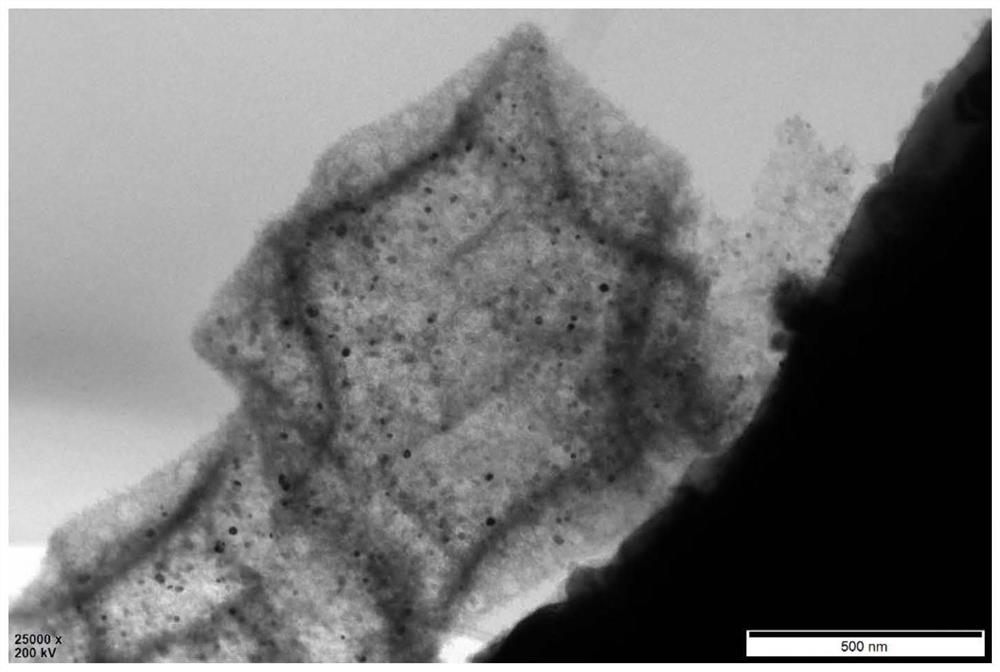

[0031] In this embodiment, a method for preparing a cobalt-nickel double-metal nitrogen-doped carbon composite material containing a single-atom active site comprises the following steps:

[0032] 1) 5.95g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 150mL methanol to prepare solution A, 6.16g 2-methylimidazole was dissolved in 150mL methanol solution to prepare solution B; solution A and solution B were mixed and stirred at room temperature for 24 hours, and the obtained The product was centrifuged at 8000rpm for 5min, washed 5 times with methanol, and then dried under vacuum at 70°C;

[0033] 2) fully dissolve the ZIF-8 nanocrystals (0.747g) obtained in step 1) in 150mL methanol for ultrasonic treatment for 5min, and mark it as solution C; then 8.75g Co(NO 3 ) 2 ·6H 2 O and 0.91g DNi were dissolved in 200mL of methanol and ultrasonically treated for 5min, marked as solution D; 9.23g of 2-methylimidazole was dissolved in 50mL of methanol, marked as solution E; then solution D wa...

Embodiment 2

[0038] In this embodiment, a method for preparing a nitrogen-doped carbon composite lithium-ion battery negative electrode material comprises the following steps:

[0039] 1) 5.95g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 150mL of methanol, and then the prepared solution was poured into 150mL of methanol solution containing 6.16g of 2-methylimidazole, mixed and stirred at room temperature for 24h, and the product obtained by the reaction was centrifuged at 8000rpm for 5min , and washed 5 times with methanol, followed by vacuum drying at 70 °C;

[0040] 2) Place the product obtained in step 1) in a tube furnace, heat it to 850°C at a heating rate of 2°C / min, and heat it under flowing N 2 Keep it for 2 hours, and cool it down to room temperature naturally to obtain the product, which is the anode material of nitrogen-doped carbon composite lithium-ion battery (as a comparative material).

[0041] The electrochemical performance test method consistent with that in Example 1 was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com