Front end motor-generator system and hybrid electric vehicle operating method

一种混合动力电动、电动发电机的技术,应用在混合动力车辆、电力制动系统、机动车等方向,能够解决增加车辆重量、辅助动力装置昂贵、工程困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

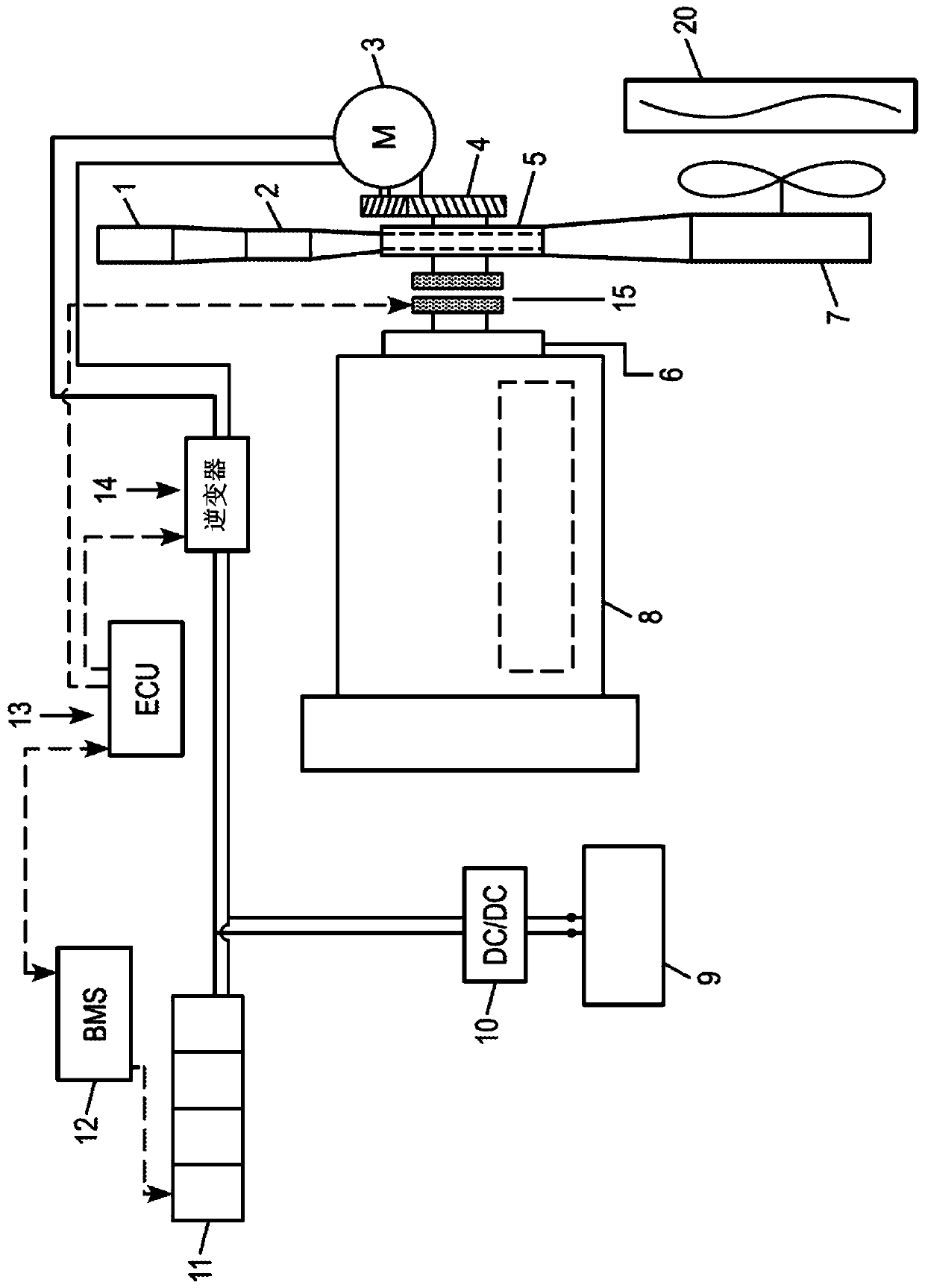

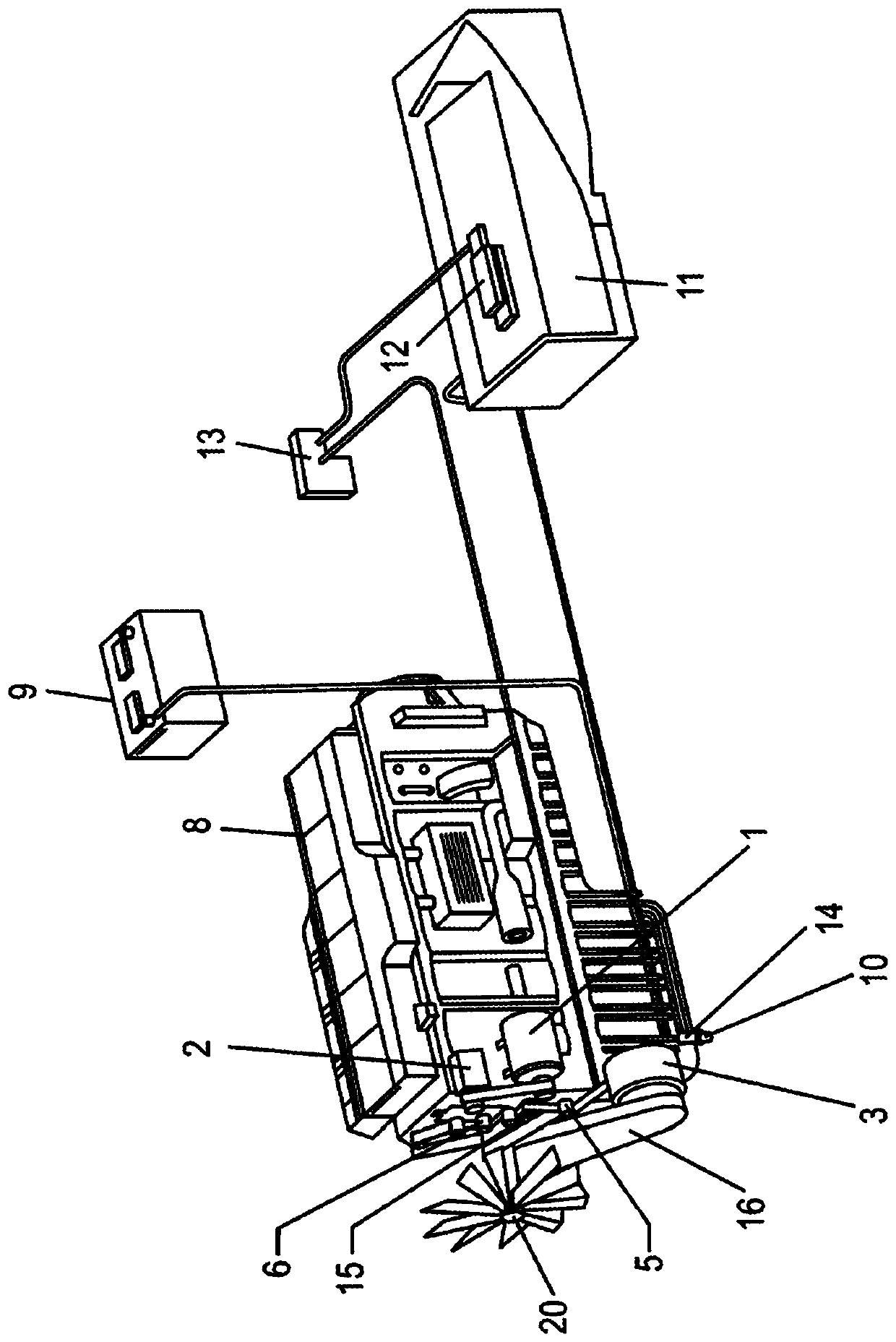

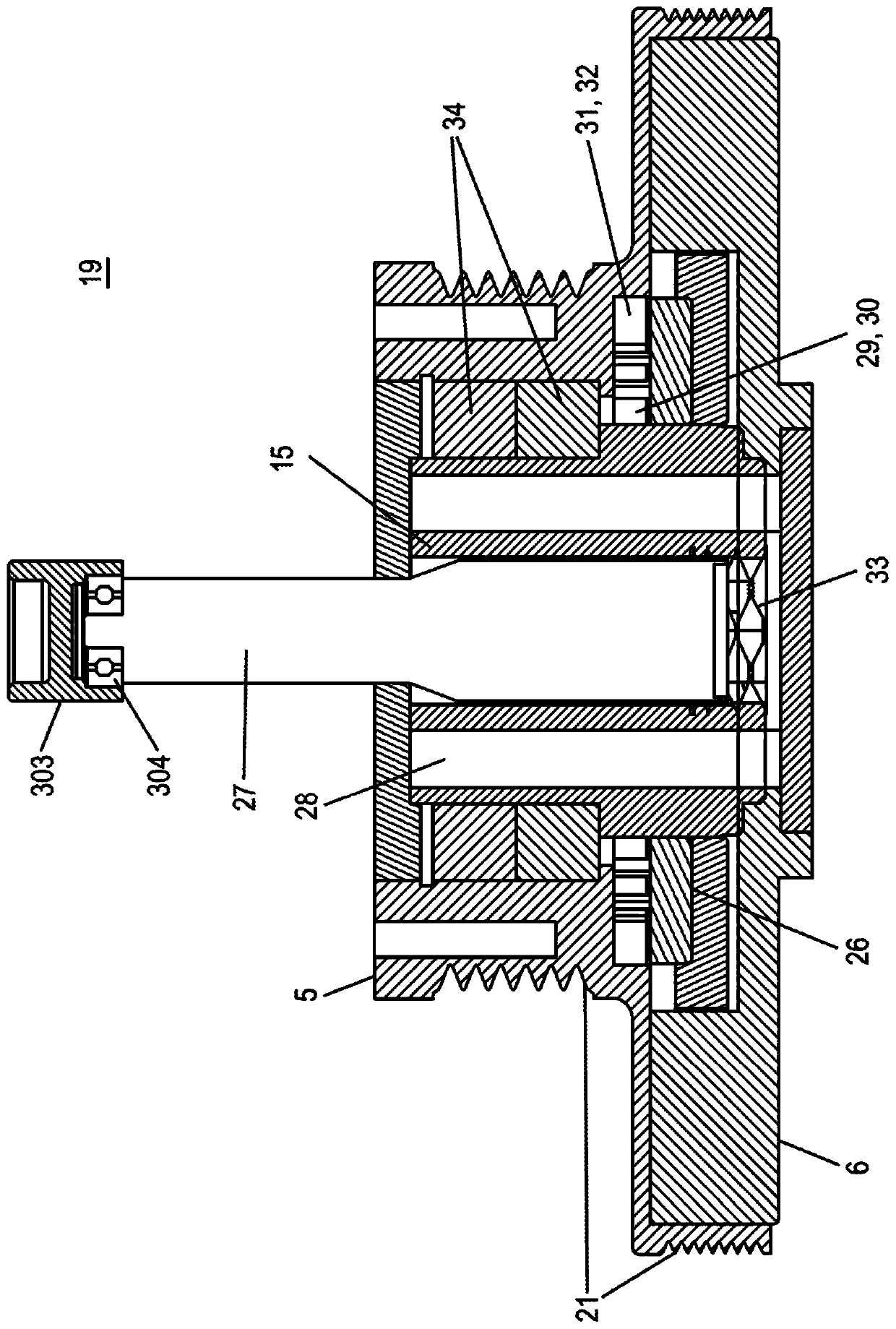

[0086] Front end motor generator system embodiment.

[0087] Figure 1A is a schematic diagram illustrating components of an embodiment of a FEMG system according to the present invention. Figure 1B is a schematic diagram of several FEMG system components in a commercial vehicle chassis. In this arrangement, the engine accessories (comprising the air compressor 1 , the air conditioner compressor 2 and the engine cooling fan 7 arranged to pull cooling air through the engine coolant radiator 20 ) are belt driven by the pulley 5 . The pulley 5 is positioned coaxially with the damper 6 , which is directly coupled to the crankshaft of the internal combustion engine 8 . The accessories can be directly driven by the belt or provided with their own on / off or variable speed clutch (not shown) which allows a separately clutched accessory to be partially or completely disengaged from the belt drive.

[0088] In addition to driving the accessory drive belt, pulley 5 is also coupled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com