Anti-splash device for operating room

An operating room and integrated technology, applied in the field of medical devices, can solve problems such as blood dripping, blood spurting at surgical incisions, and blood cannot be blocked, achieving good stability, long service life, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

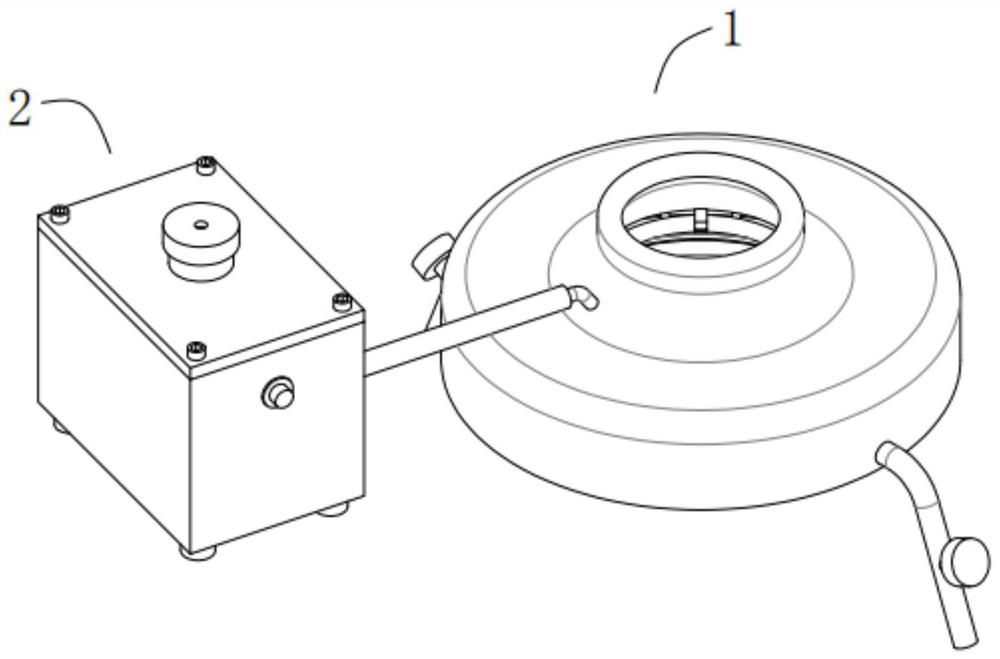

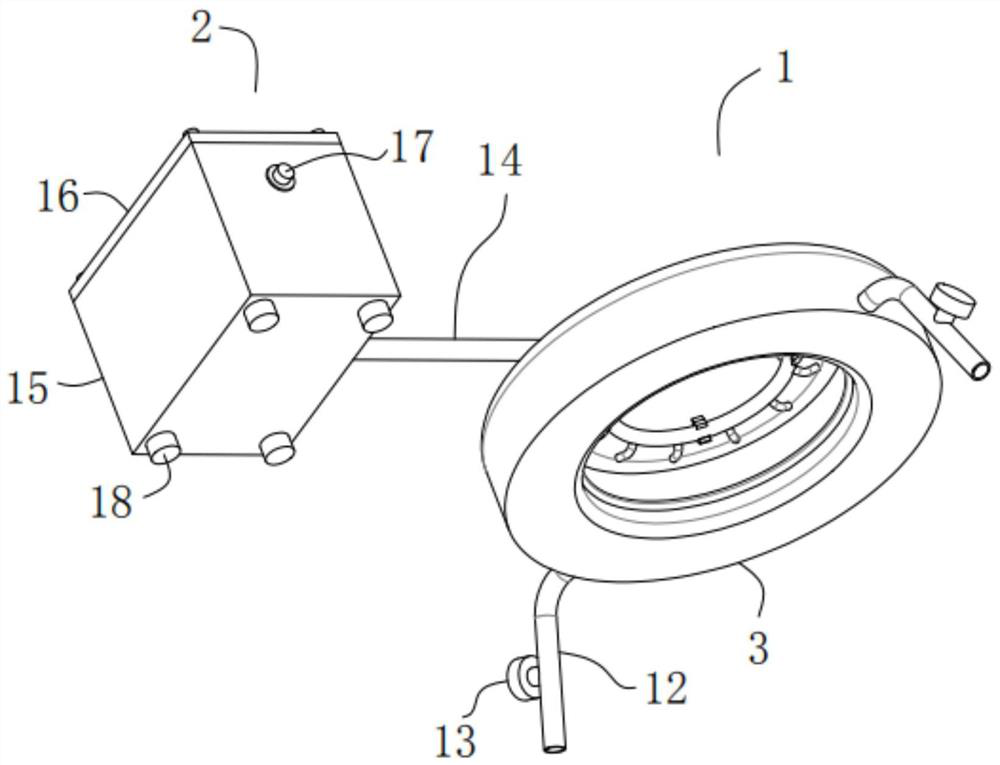

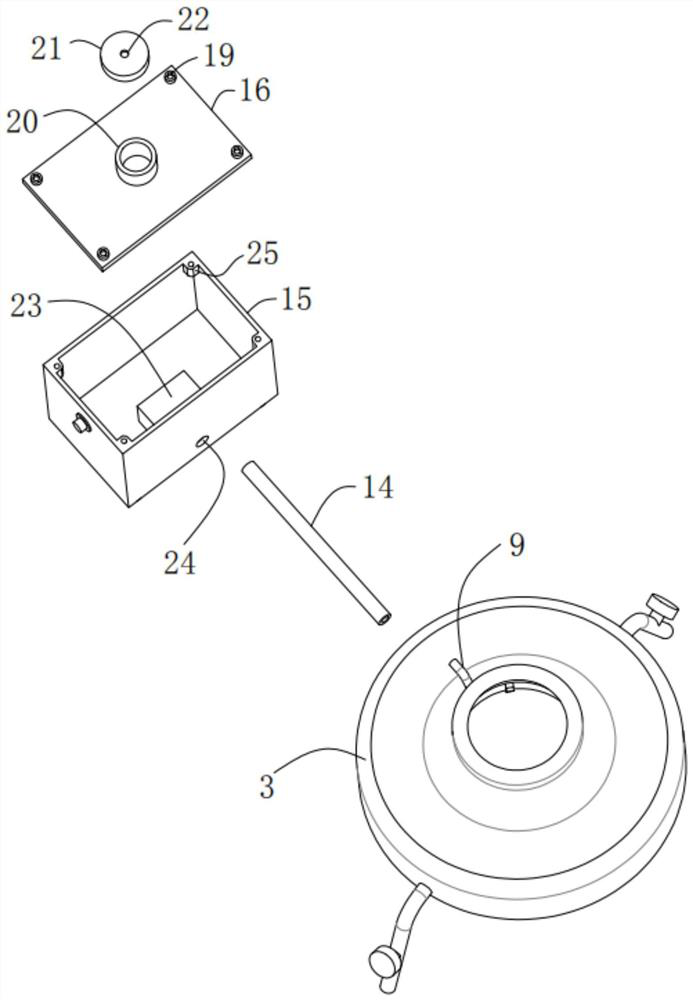

[0057] A kind of anti-splash device for operating room, such as figure 1 and 4 As shown in -9, it includes a shielding part 1, and the shielding part 1 includes a cylindrical shell 3, a flange 4 and a discharge pipe 12, the upper end of the cylindrical shell 3 is a closed structure, and the cylindrical shell The bottom end of the body 3 is an open structure, and the inside of the cylindrical shell 3 is aligned with its bottom edge to be integrally provided with a liquid storage tank 11 , and the collar 4 is integrally provided on the upper end wall of the cylindrical shell 3 center position, and the flange 4 communicates with the interior of the cylindrical housing 3, the drain pipe 12 is fixedly installed on the outer wall of the cylindrical housing 3, and the drain The tube 12 is arranged close to the bottom of the cylindrical shell 3 , one end of the drain tube 12 communicates with the bottom of the liquid storage tank 11 , and the other end of the drain tube 12 is a free ...

Embodiment 2

[0081] The difference from Example 1 is that a protective layer is also provided on the inner wall of the cylindrical shell 3 and the collar 4, and the protective layer is prepared by the following method:

[0082] Take the following raw materials and weigh them by weight: 7 parts of polyvinyl alcohol, 7 parts of polyvinylpyrrolidone, 6 parts of epoxy resin, 5 parts of p-toluenesulfonic acid, 3 parts of acrylic acid, 4 parts of lotus leaf hydrophobic agent, 5 parts of polytetrafluoroethylene 8 parts of polyethylene glycol, 4 parts of n-butanol, 2 parts of glycerin and 20 parts of purified water;

[0083] S1. Add the weighed epoxy resin and polytetrafluoroethylene into the pulverizer and pulverize to a powdery material with particles no larger than 100nm;

[0084] S2, the weighed polyvinyl alcohol, polyvinylpyrrolidone, epoxy resin, p-toluenesulfonic acid, acrylic acid, lotus leaf hydrophobic agent, polytetrafluoroethylene, polyethylene glycol, n-butanol, glycerin and purified ...

Embodiment 3

[0090] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0091] Take the following raw materials and weigh them by weight: 10 parts of polyvinyl alcohol, 10 parts of polyvinyl pyrrolidone, 7 parts of epoxy resin, 7 parts of p-toluenesulfonic acid, 4 parts of acrylic acid, 5 parts of lotus leaf hydrophobic agent, 6 parts of polytetrafluoroethylene 7 parts of polyethylene glycol, 5 parts of n-butanol, 3 parts of glycerin and 22 parts of purified water;

[0092] S1. Add the weighed epoxy resin and polytetrafluoroethylene into the pulverizer and pulverize to a powdery material with particles no larger than 100nm;

[0093] S2, the weighed polyvinyl alcohol, polyvinylpyrrolidone, epoxy resin, p-toluenesulfonic acid, acrylic acid, lotus leaf hydrophobic agent, polytetrafluoroethylene, polyethylene glycol, n-butanol, glycerin and purified water and All the powdery materials prepared in step S1 are put into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com