Anti-febrile gel film patch and preparation method and application thereof

The technology of a gel film and a gel layer is applied in the field of antipyretic gel film stickers and their preparation, and achieves the effects of being suitable for industrial production, comfortable and cool for sticking, and efficient transdermal absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

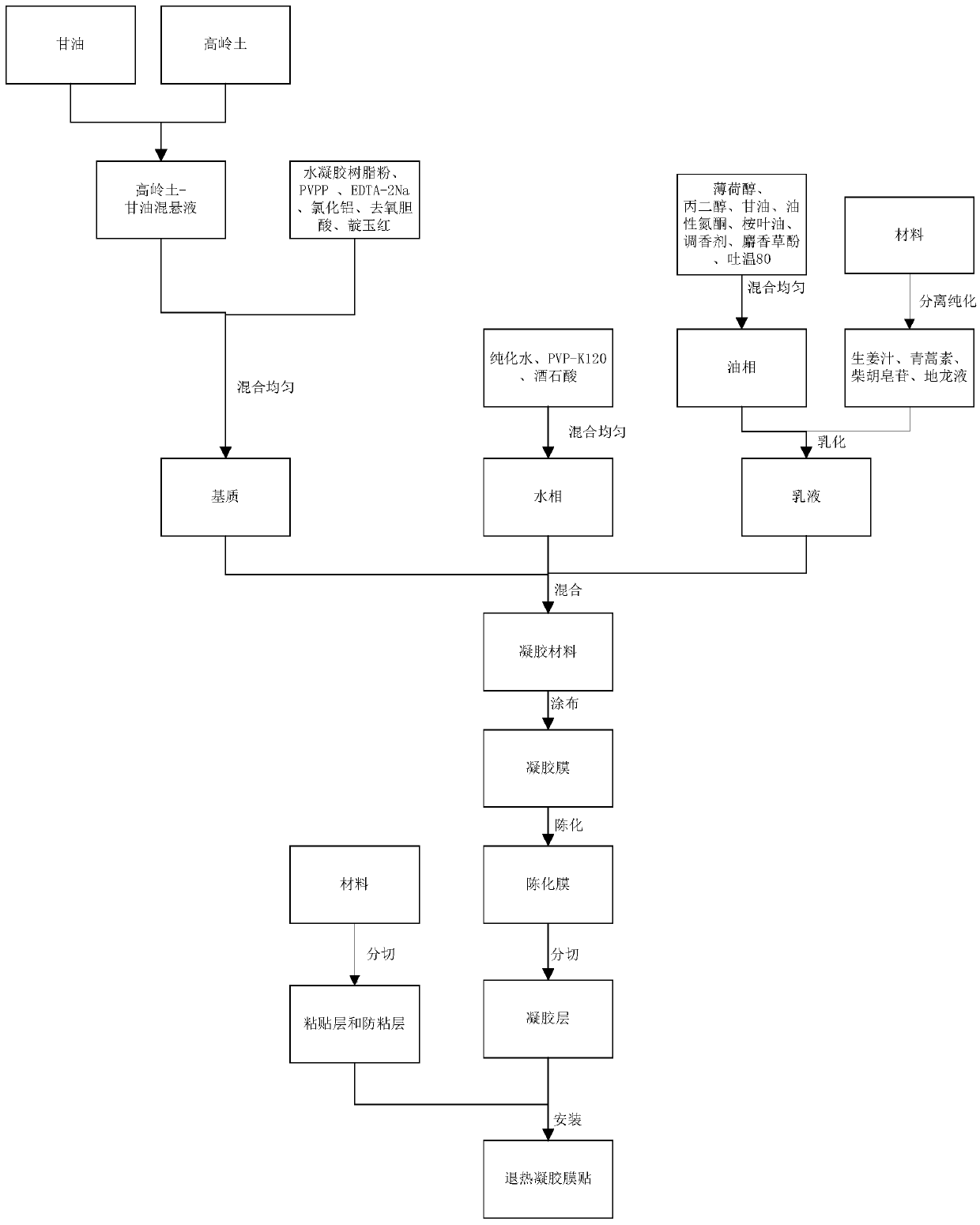

Method used

Image

Examples

Embodiment 1

[0056] In parts by weight, weigh 15 parts of glycerin and 10 parts of kaolin and mix them, stir at a speed of 250r / min until the kaolin is fully dispersed in glycerin to obtain a kaolin-glycerin suspension; Add 2.5 parts of hydrogel resin powder, 2.5 parts of PVPP, 0.05 part of EDTA-2Na, 0.25 part of aluminum chloride, 0.1 part of deoxycholic acid, and 0.2 part of indirubin to the liquid in sequence, and stir at a speed of 250r / min until the material Thoroughly mix evenly to obtain the matrix;

[0057] In parts by weight, 5 parts of PVP-K120 and 0.5 parts of tartaric acid were sequentially added to 56.65 parts of purified water, and stirred at a speed of 250 r / min until fully mixed to obtain an aqueous phase;

[0058] In parts by weight, 2.5 parts of propylene glycol, 2.5 parts of glycerin, 2.5 parts of oily azone, 1.5 parts of eucalyptus oil, 0.005 parts of flavoring agent, 1.5 parts of thymol, and 0.3 parts of Tween 80 were added successively to 2.5 parts of menthol , stirr...

Embodiment 2

[0063] In parts by weight, weigh 12 parts of glycerin and 6 parts of kaolin and mix them, stir at a speed of 250r / min until the kaolin is fully dispersed in glycerin to obtain a kaolin-glycerin suspension; Add 1.5 parts of hydrogel resin powder, 2.0 parts of PVPP, 0.03 parts of EDTA-2Na, 0.3 parts of starch aluminum, 0.2 parts of deoxycholic acid, and 0.5 parts of indirubin to the liquid in sequence, and stir at a speed of 250 r / min until the materials are fully Mix evenly to obtain the matrix;

[0064] In parts by weight, 3.5 parts of PVP-K120 and 0.2 parts of tartaric acid were sequentially added to 69.94 parts of purified water, and stirred at a speed of 220 r / min until fully mixed to obtain a water phase;

[0065] In parts by weight, sequentially add 1.5 parts of propylene glycol, 1.5 parts of glycerin, 1.5 parts of oily azone, 1 part of eucalyptus oil, 0.003 parts of flavoring agent, 1 part of thymol, and 0.2 parts of Tween 80 into 1.5 parts of menthol , stirring at a ra...

Embodiment 3

[0069]In parts by weight, weigh 13 parts of glycerin and 12 parts of kaolin and mix them, and stir at a speed of 250r / min until the kaolin is fully dispersed in glycerin to obtain a kaolin-glycerin suspension; Add 4.0 parts of hydrogel resin powder, 4.5 parts of PVPP, 0.08 parts of EDTA-2Na, 0.2 parts of aluminum chloride, 0.5 parts of deoxycholic acid, and 0.3 parts of indirubin to the liquid in sequence, and stir at a speed of 250r / min until the material Thoroughly mix evenly to obtain the matrix;

[0070] In parts by weight, 8 parts of PVP-K120 and 0.8 parts of tartaric acid were sequentially added to 52 parts of purified water, and stirred at a speed of 260 r / min until fully mixed to obtain an aqueous phase;

[0071] In parts by weight, sequentially add 4.5 parts of propylene glycol, 4.5 parts of glycerin, 4.5 parts of oily azone, 2 parts of eucalyptus oil, 0.008 parts of flavoring agent, 2 parts of thymol, and 0.4 parts of Tween 80 into 4.0 parts of menthol , stirring at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com