High-frequency ultralow-consumption manganese-zinc soft magnetic ferrite material and preparation method thereof

A manganese-zinc soft magnet and soft ferrite technology, applied in the direction of inorganic material magnetism, can solve the problems of low applicable frequency, high sintering temperature, large power loss of magnetic core, etc., and achieve miniaturization, good comprehensive performance, energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

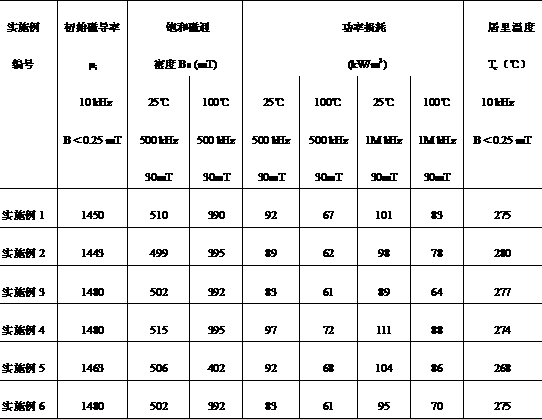

Examples

Embodiment 1

[0023] A high-frequency ultra-low loss manganese-zinc soft magnetic ferrite material and its preparation method, including main components and additive components, the main component and the first additive are commercially available as chemically pure raw materials, including the following components in parts by weight :

[0024] Fe 2 o 3 142 kg, Mn 3 o 4 45 kg, ZnO 13 kg, CaCO 3 180g, CoO 380g, Cr 2 o 3 320g;

[0025] The second additive composition except SiO 2 Except for the particle size of 50nm~100nm, the rest are commercially available and chemically pure raw materials, including the following doping components:

[0026] Y 2 o 3 20g, Sm 2 o 3 5g, SiO 2 40g, V 2 o 5 50g;

[0027] A method for preparing a high-frequency ultra-low loss manganese-zinc soft ferrite material, comprising the following steps:

[0028] (1) The primary ingredient is configured according to the above mass and weighs 200kg of the main component Fe 2 o 3 , Mn 3 o 4 and Zn...

Embodiment 2

[0035] A high-frequency ultra-low loss manganese-zinc soft magnetic ferrite material and its preparation method, including main components and additive components, the main component and the first additive are commercially available as chemically pure raw materials, including the following components in parts by weight :

[0036] Fe 2 o 3 142 kg, Mn 3 o 4 45 kg, ZnO 13 kg, CaCO 3 180g, CoO 380g, Cr 2 o 3 320g;

[0037] The second additive composition except SiO 2 Except for the particle size of 50nm~100nm, the rest are commercially available and chemically pure raw materials, including the following doping components:

[0038] Y 2 o 3 20g, Sm 2 o 3 7g, SiO 2 40g, V 2 o 5 50g;

[0039] A high-frequency ultra-low loss manganese-zinc soft ferrite material and a preparation method thereof, comprising the following steps:

[0040] (1) The primary ingredient is configured according to the above mass and weighs 200kg of the main component Fe 2 o 3 , Mn 3 o ...

Embodiment 3

[0047] A high-frequency ultra-low loss manganese-zinc soft ferrite material and a preparation method thereof, including a main component and an additive component; the main component and the first additive are commercially available chemically pure raw materials, including the following components by weight:

[0048] Fe 2 o 3 142 kg, Mn 3 o 4 45 kg, ZnO 13 kg, CaCO 3 180g, CoO 380g, Cr 2 o 3 320g;

[0049] The second additive composition except SiO 2 Except for the particle size of 50nm~100nm, the rest are commercially available and chemically pure raw materials, including the following doping components:

[0050] Y 2 o 3 20g, Sm 2 o 3 9g, SiO 2 40g, V 2 o 5 50g;

[0051] A high-frequency ultra-low loss manganese-zinc soft ferrite material and a preparation method thereof, comprising the following steps:

[0052] (1) The primary ingredient is configured according to the above mass and weighs 200kg of the main component Fe 2 o 3 , Mn 3 o 4 and ZnO, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com