Magnesium calcium ammonium nitrate granular fertilizer and preparation method thereof

A technology of ammonium nitrate, calcium and magnesium, granular fertilizer, applied in the direction of ammonium nitrate fertilizer, nitrate fertilizer, ammonium salt fertilizer, etc., can solve the problems of underutilization of resources, environmental groundwater pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

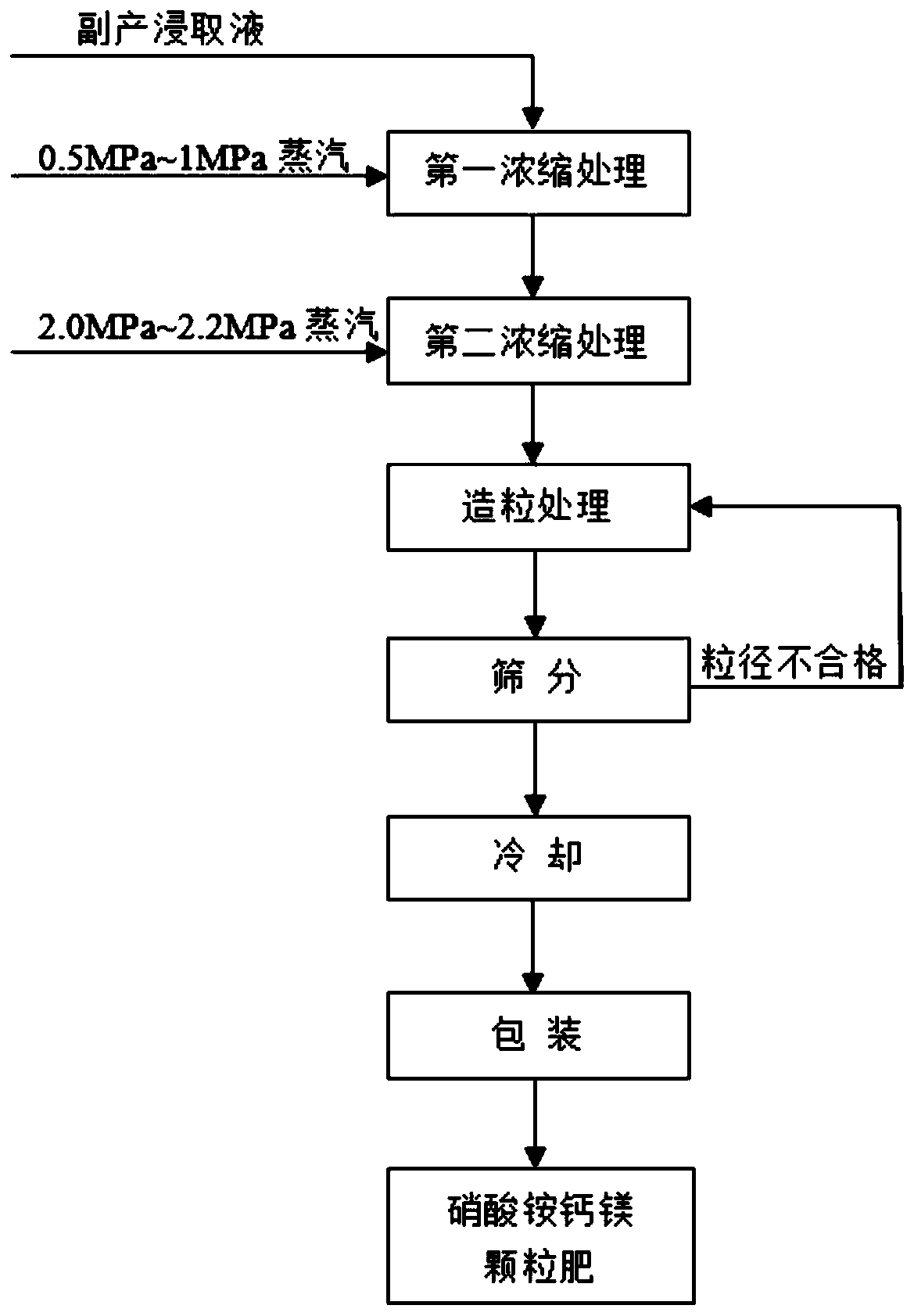

[0030] The preparation method of the ammonium nitrate calcium magnesium granule fertilizer of one embodiment, comprises the steps:

[0031] Step S110: Prepare low-magnesium phosphorus concentrate with medium and low-grade phosphate rock as raw material, and obtain leaching solution. Wherein, the main component of above-mentioned leaching liquid comprises: Ca(NO 3 ) 2 , Mg(NO 3 ) 2 , NH 4 NO 3 , NH 4 OH and H 2 O.

[0032] It can be understood that the leaching solution in the above step S110 is based on low- and medium-grade phosphate rock as raw material, after calcination, digestion, and wet ball milling, the by-products when leaching and preparing low-magnesium phosphorus concentrate can be obtained from special phosphorus ore. It can be purchased from ore processing factories, and can also be prepared through the following steps:

[0033] Step S111: Crushing, calcining, and wet ball milling the medium and low-grade phosphate rock to obtain a pretreated product.

...

Embodiment 1

[0058] The ammonium nitrate calcium magnesium granule fertilizer of this implementation and preparation steps are as follows:

[0059] (1) The medium and low grade phosphate rock (P 2 o 5 25.12%) crushed to less than 4.0mm, calcined, cooled, ground to less than 0.5mm in particle size, digested, leached, and washed by pressure filtration to obtain 6000kg of leaching solution, which was pumped to the concentration system (two-effect countercurrent evaporator device). Enter the low-pressure steam of 0.69MPa, through the first concentrated treatment, obtain the first concentrated liquid;

[0060] (2) Pump the above-mentioned first concentrate to the preheater, use the condensate produced by 2.0MPa medium-pressure steam as the heating medium, transport it to the heat exchanger after preheating, and then transport it to the forced Circulating evaporator, and then mixed with the first concentrated liquid to be heated through a heat exchanger and lowered to 98°C to 102°C to obtain ...

Embodiment 2~4

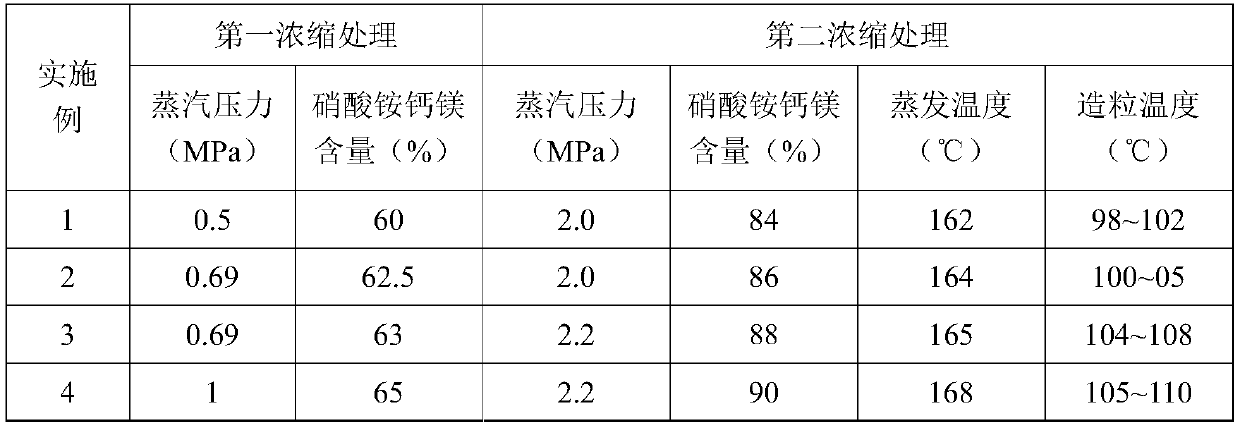

[0064] The preparation steps of the ammonium calcium magnesium nitrate granule fertilizer in Examples 2-4 are the same as those in Example 1, only the process parameters involved are different. For the specific process parameters, please refer to Table 1 below.

[0065] The processing parameters when each embodiment of table 1 prepares ammonium nitrate calcium magnesium granule fertilizer

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com