Method for preparing chemicals by lignocellulose all-component higher value application

A lignocellulosic and full-component technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult lignocellulosic raw material component utilization and low yield, and achieve reduced losses , reduce production costs, and efficiently utilize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

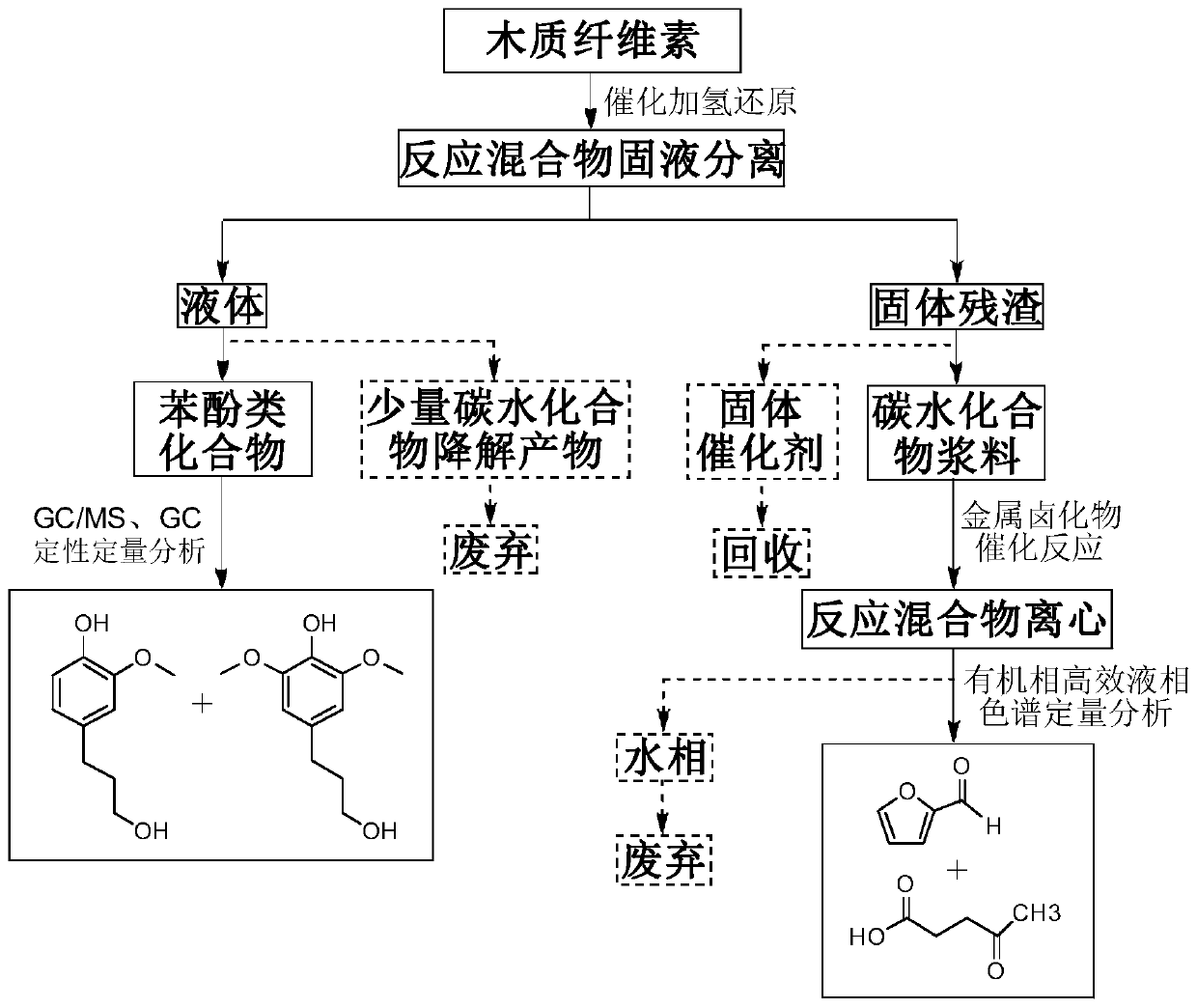

Method used

Image

Examples

Embodiment 1

[0084] (1) Get 10g of eucalyptus with a particle size of 40-60 mesh, add 400mL of methanol and 10wt% Pd / C catalyst, put it into a stainless steel reactor and feed nitrogen to replace the air therein, and then feed 3MPa hydrogen;

[0085] (2) heating the mixture obtained in step (1) to 260° C. for 10 h;

[0086] (3) The solid-liquid separation of the reaction mixture obtained in step (2), the liquid is obtained by rotary evaporation and extraction to obtain phenolic compounds, and the solid residue is recovered by sieving the catalyst;

[0087] (4) Take 1.5 g of the solid carbohydrate residue obtained in step (3) and add 150 mL of MeTHF / NaCl (3:1) solution and 0.1 M FeCl 3 catalyst;

[0088] (5) Heat the mixture obtained in step (4) to 170° C. for 40 minutes, and obtain furfural and levulinic acid in the organic phase by centrifugation;

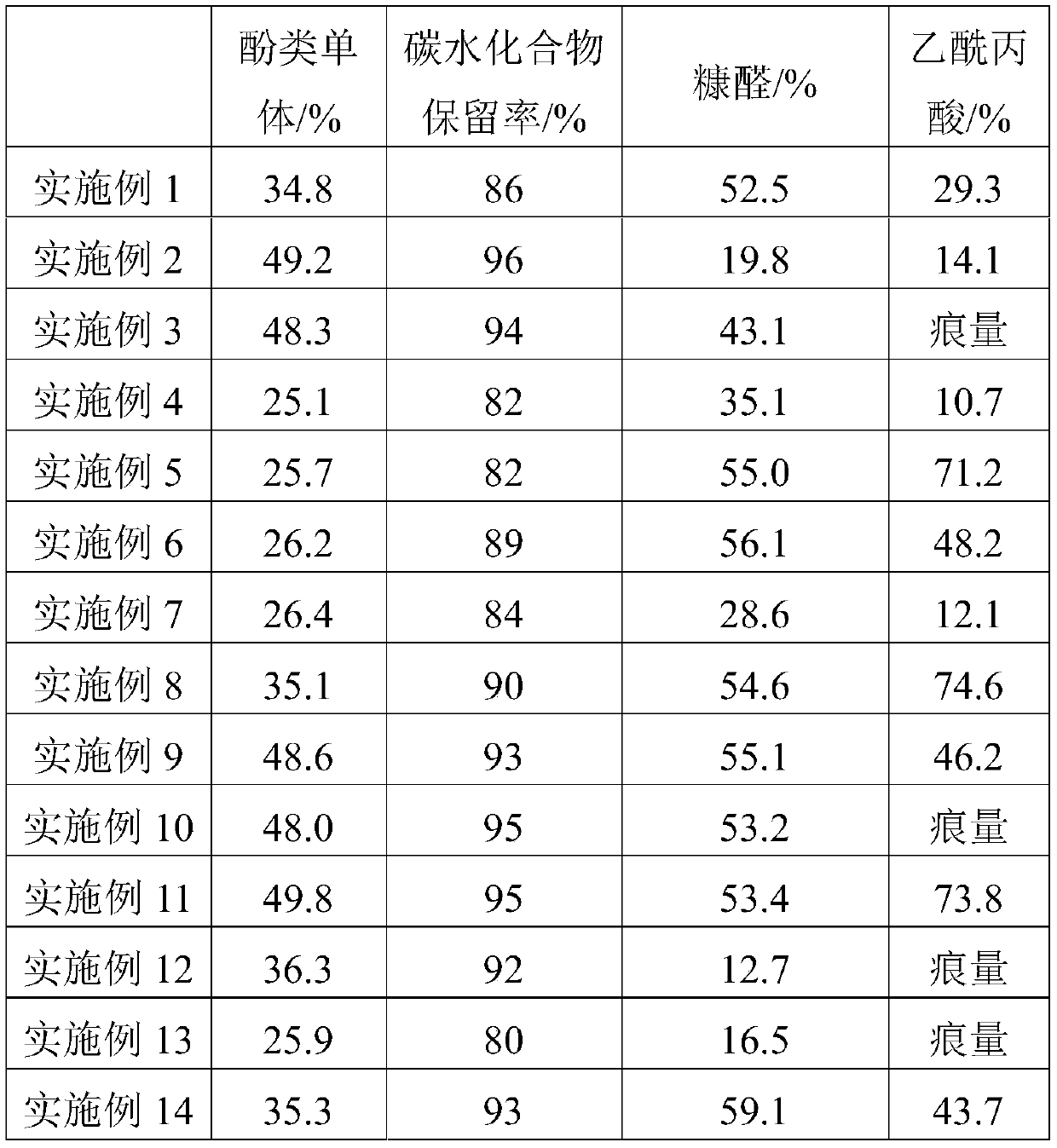

[0089] (6) Test the yield of phenolic monomers, furfural and levulinic acid in this embodiment, and the retention rate of carbohydrates aft...

Embodiment 2

[0091] (1) Take 10g of eucalyptus wood with a particle size of 40-60 mesh, add 400mL of ethanol and 10wt% Ru / C catalyst, put it into a stainless steel reactor and feed nitrogen, replace the air therein, and then feed 4MPa hydrogen;

[0092] (2) The mixture obtained in step (1) was heated to 240° C. for 4 hours;

[0093] (3) The solid-liquid separation of the reaction mixture obtained in step (2), the liquid is obtained by rotary evaporation and extraction to obtain phenolic compounds, and the solid residue is recovered by sieving the catalyst;

[0094] (4) Take 1.5 g of the solid carbohydrate residue obtained in step (3) and add 150 mL of MeTHF / NaCl (1:0) solution and 0.1 M FeCl 3 catalyst;

[0095] (5) Warm up the mixture obtained in step (4) to 190°C for 120 minutes, and obtain furfural and levulinic acid in the organic phase by centrifugation;

[0096] (6) Test the yield of phenolic monomers, furfural and levulinic acid in this embodiment, and the retention rate of carboh...

Embodiment 3

[0098] (1) Take 10g of birch wood with a particle size of 40-60 mesh, add 400mL of methanol and 10wt% Pd / C catalyst, put it into a stainless steel reactor and feed nitrogen to replace the air, and then feed 4MPa hydrogen;

[0099] (2) The mixture obtained in step (1) was heated to 240° C. for 8 hours;

[0100] (3) The solid-liquid separation of the reaction mixture obtained in step (2), the liquid is obtained by rotary evaporation and extraction to obtain phenolic compounds, and the solid residue is recovered by sieving the catalyst;

[0101] (4) Take 1.5 g of the solid carbohydrate residue obtained in step (3) and add 150 mL of THF / NaCl (3:1) solution and 0.1 M FeCl 3 catalyst;

[0102] (5) Warm up the mixture obtained in step (4) to 170°C for 100 min, and obtain furfural and levulinic acid in the organic phase by centrifugation;

[0103] (6) Test the yield of phenolic monomers, furfural and levulinic acid in this embodiment, and the retention rate of carbohydrates after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com