High-definition wood grain transfer powder paint with graffiti resistance, preparation method and use thereof

A powder coating and anti-graffiti technology, applied in the field of coatings, can solve the problems of poor coating toughness and water resistance, blurred transfer pattern, poor anti-graffiti and other problems, and achieves good water resistance, highly clear pattern, and anti-graffiti effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

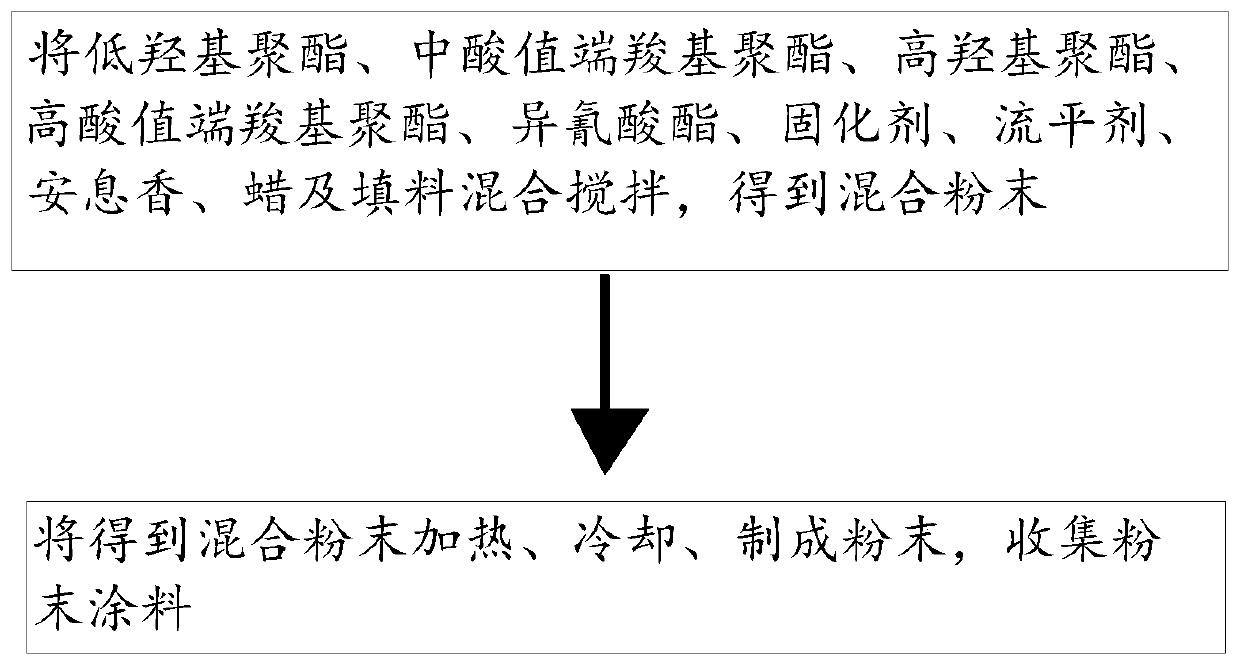

Method used

Image

Examples

Embodiment 1

[0039] Preparation process of high-definition wood grain transfer powder coating A with anti-graffiti:

[0040] 200 parts of low hydroxyl polyester, 200 parts of medium acid value carboxyl terminal polyester, 200 parts of high hydroxyl polyester, 200 parts of high acid value carboxyl terminal polyester, 400 parts of isocyanate, 20 parts of curing agent, 15 parts of leveling agent, Mix 5 parts of benzoin, 10 parts of wax, 300 parts of filler and 50 parts of pigment, heat and melt the mixed powder, blend and extrude the clinker into clinker; cool the clinker by tableting, crushing, crushing, grading and sieving, and collect the powder coating , to obtain anti-graffiti high-definition wood grain transfer powder coating A;

[0041] Wherein, the hydroxyl value of the low-hydroxyl polyester is 50 mgKOH / g; the acid value of the medium acid value carboxyl-terminated polyester is 45 mgKOH / g; the hydroxyl value of the high-hydroxyl polyester is 320 mgKOH / g; the high Acid Value The acid...

Embodiment 2

[0052] Preparation process of high-definition wood grain transfer powder coating C with anti-graffiti:

[0053] 50 parts of low hydroxyl polyester, 50 parts of medium acid value carboxyl terminated polyester, 50 parts of high hydroxyl polyester, 50 parts of high acid value carboxyl terminated polyester, 230 parts of isocyanate, 10 parts of curing agent, 5 parts of leveling agent, Mix 1 part of benzoin, 2 parts of wax, 150 parts of filler and 10 parts of pigment, heat and melt the mixed powder, blend and extrude the clinker; cool the clinker by tableting, crushing, crushing, grading and sieving, and collect the powder coating , to obtain anti-graffiti high-definition wood grain transfer powder coating C;

[0054] Wherein, the hydroxyl value of the low-hydroxyl polyester is 20; the acid value of the medium acid value carboxyl-terminated polyester is 28; the hydroxyl value of the high-hydroxyl polyester is 90; the high acid value carboxyl-terminated polyester The acid value is 4...

Embodiment 3

[0059] Preparation process of high-definition wood grain transfer powder coating D with anti-graffiti:

[0060] 150 parts of low hydroxyl polyester, 150 parts of medium acid value carboxyl terminal polyester, 150 parts of high hydroxyl polyester, 150 parts of high acid value carboxyl terminal polyester, 300 parts of isocyanate, 15 parts of curing agent, 10 parts of leveling agent, Mix 3 parts of benzoin, 5 parts of wax, 200 parts of filler and 30 parts of pigment, heat and melt the mixed powder, blend and extrude the clinker; cool the clinker by tableting, crushing, crushing, grading and sieving, and collect the powder coating , to obtain anti-graffiti high-definition wood grain transfer powder coating D;

[0061] Wherein, the hydroxyl value of the low-hydroxyl polyester is 30 mgKOH / g; the acid value of the medium acid value carboxyl-terminated polyester is 30 mgKOH / g; the hydroxyl value of the high-hydroxyl polyester is 180 mgKOH / g; the high Acid Value The acid value of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com