Silicon-carbon composite electrode material and preparation method thereof

An electrode material, carbon-silicon composite technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of loss of electrical contact performance of active centers, low electrochemical energy absorption of batteries, affecting chemical cycles, etc., to improve electrochemical performance. , good mechanical stability, the effect of reducing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a Si / C composite material, which is prepared by the following method:

[0058] S1: Dissolving the pitch of the reaction precursor in an organic solution such as tetrahydrofuran or acetone to form a first mixed solution;

[0059] S2: After adding an appropriate amount of graphite with an average particle size of 1 micron into the first mixed solution, vibrate in an ultrasonic oscillator for 15 minutes, and form a second mixed solution after the graphite is uniformly dispersed;

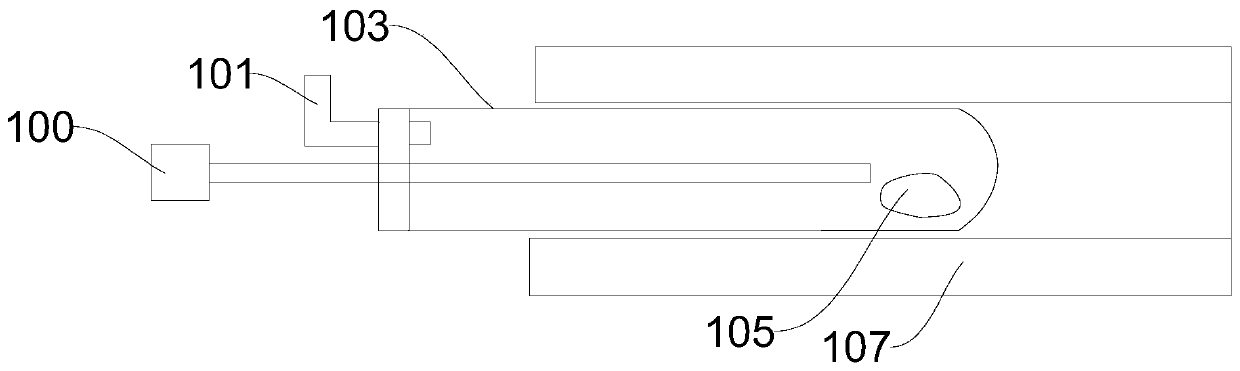

[0060] S3: Add the silicon powder as the active center into the second mixed solution, and stir to form a uniform slurry, stir evenly at room temperature, and transfer it to the quartz tube 103 after volatilizing at room temperature, and pass through the quartz tube 103 at the same time Into a protective atmosphere, heat treatment at 900 ° C to prepare composite materials.

Embodiment 2

[0062] This embodiment also provides a Si-Al / C composite material, which is prepared by the following method:

[0063] S1: Mix silicon powder and fine aluminum powder with a particle size of 5 microns in a mass ratio of 5:1;

[0064] S2: After ball milling and mixing in the Ar ball milling atmosphere, in the mixed gas (4%H 2 , under the protection of 96% Ar), and after heat treatment at 600 degrees, it is prepared into a composite material precursor;

[0065] S3: Dissolve an appropriate amount of asphalt in acetone, stir evenly, slowly add graphite powder with a particle size of 1-2 microns, gently stir and grind properly;

[0066] S4: Add the heat-treated silicon / aluminum powder into the asphalt solution and stir evenly. At room temperature, after the solvent is volatilized, the mixture is transferred into a quartz tube 103, placed in a furnace body 107, and heat-treated at 900° C. to prepare a composite material.

[0067] The content of each component of the Si-Al / C compo...

Embodiment 3

[0069] This embodiment provides a Si / C composite material, which is prepared by the following method:

[0070] S1: dissolving 50 grams of reactant asphalt in isopropanol to form a first mixed solution;

[0071] S2: After fully stirring for 30 minutes, add 25 grams of graphite with a D50 of 1 micron into the first mixed solution, and vibrate in an ultrasonicator for 15 minutes to form a second mixed solution;

[0072] S3: After the graphite is uniformly dispersed, add 10 grams of silicon powder as the active center into it and stir thoroughly. Stir fully at room temperature, place in a fume hood, and after the solvent is volatilized, transfer to the quartz tube 103, and pass through protective gas (4%H 2 , 96% Ar) after heat treatment, and the temperature gradient of the heat treatment is to increase the temperature to 900 ° C, and gradually cool down after 3 hours of reaction to take it out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com