A kind of freeze-dried powder and its preparation process

A technology of freeze-dried powder and phase B, which is applied to cosmetic preparations, cosmetic preparations, preparations for skin care, etc., can solve the problems of short shelf life, incomplete function, complicated preparation process, etc. The effect of immunity, thickening of sebum film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

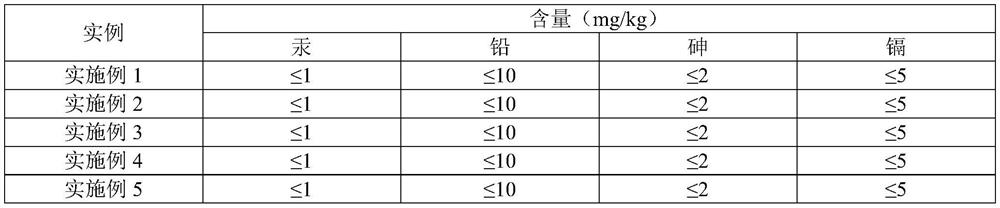

Embodiment 1

[0034] A freeze-dried powder for repairing problem skin, including phase A and phase B, phase A includes: 1 part of oligopeptide-1, 1 part of oligopeptide-3, 8 parts of lactobacillus / North American holy grass fermentation product extract, 6 parts ceramide 3 and 66 parts water;

[0035] Phase B includes, in parts by weight: 5 parts of oat β-glucan, 12 parts of purslane extract and 1 part of sodium hyaluronate.

[0036] The preparation method of this lyophilized powder comprises the following steps:

[0037] (1) Sterilize the water in phase A at 120°C and pressure of 103.4kPa for 22 minutes and cool it down to room temperature, then add other raw materials in phase A except water;

[0038] (2) Add phase B to phase A, shake well and filter with a 0.2 μm filter membrane to obtain a mixed material;

[0039](3) After filling the mixed material in step (2), pre-freeze at -30°C for 2.5h, in a vacuum of less than 1mmHg, at a temperature of -20°C, sublimation and dry for 12h, and then...

Embodiment 2

[0041] A freeze-dried powder for repairing problematic skin, comprising phase A and phase B, the phase A comprising: 3 parts of oligopeptide-1, 3 parts of oligopeptide-3, 16 parts of Lactobacillus / Holy Grass Fermentation product extract, 10 parts ceramide 3 and 38 parts water;

[0042] The phase B includes, in parts by weight: 9 parts of oat β-glucan, 18 parts of purslane extract and 3 parts of sodium hyaluronate.

[0043] The preparation method of this lyophilized powder comprises the following steps:

[0044] (1) Sterilize the water in phase A at 130°C and a pressure of 103.4kPa for 15 minutes and cool it down to room temperature, then add other raw materials in phase A except water;

[0045] (2) Add phase B to phase A, shake well and filter with a 0.2 μm filter membrane to obtain a mixed material;

[0046] (3) After filling the mixed material in step (2), it is pre-frozen at -40°C for 0.5h, and the vacuum degree is less than 1mmHg, the temperature is -20°C, sublimated and...

Embodiment 3

[0048] A freeze-dried powder for repairing problematic skin, comprising phase A and phase B, the phase A comprising: 2 parts of oligopeptide-1, 1.4 parts of oligopeptide-3, 12.3 parts of Lactobacillus / Holy Grass Fermentation product extract, 8.2 parts of ceramide 3 and 53.3 parts of water;

[0049] The phase B includes, in parts by weight: 7 parts of oat β-glucan, 14 parts of purslane extract and 1.8 parts of sodium hyaluronate.

[0050] The preparation method of this lyophilized powder comprises the following steps:

[0051] (1) Sterilize the water in phase A at 125°C and the pressure of 103.4kPa for 20 minutes and cool it down to room temperature, then add other raw materials in phase A except water;

[0052] (2) Add phase B to phase A, shake well and filter with a 0.2 μm filter membrane to obtain a mixed material;

[0053] (3) After filling the mixed material in step (2), pre-freeze at -30°C for 1 hour, in a vacuum of less than 1mmHg, at a temperature of -20°C, sublimate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com