Environment-friendly kitchen waste treatment device

A kitchen waste and processing device technology, applied in grain processing, transportation and packaging, drying gas layout, etc., can solve the problems of resource waste, solid-liquid separation of kitchen waste, inability to recycle kitchen waste, etc. Efficiency improvement, reducing the possibility of bacteria and mosquito breeding, and speeding up drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

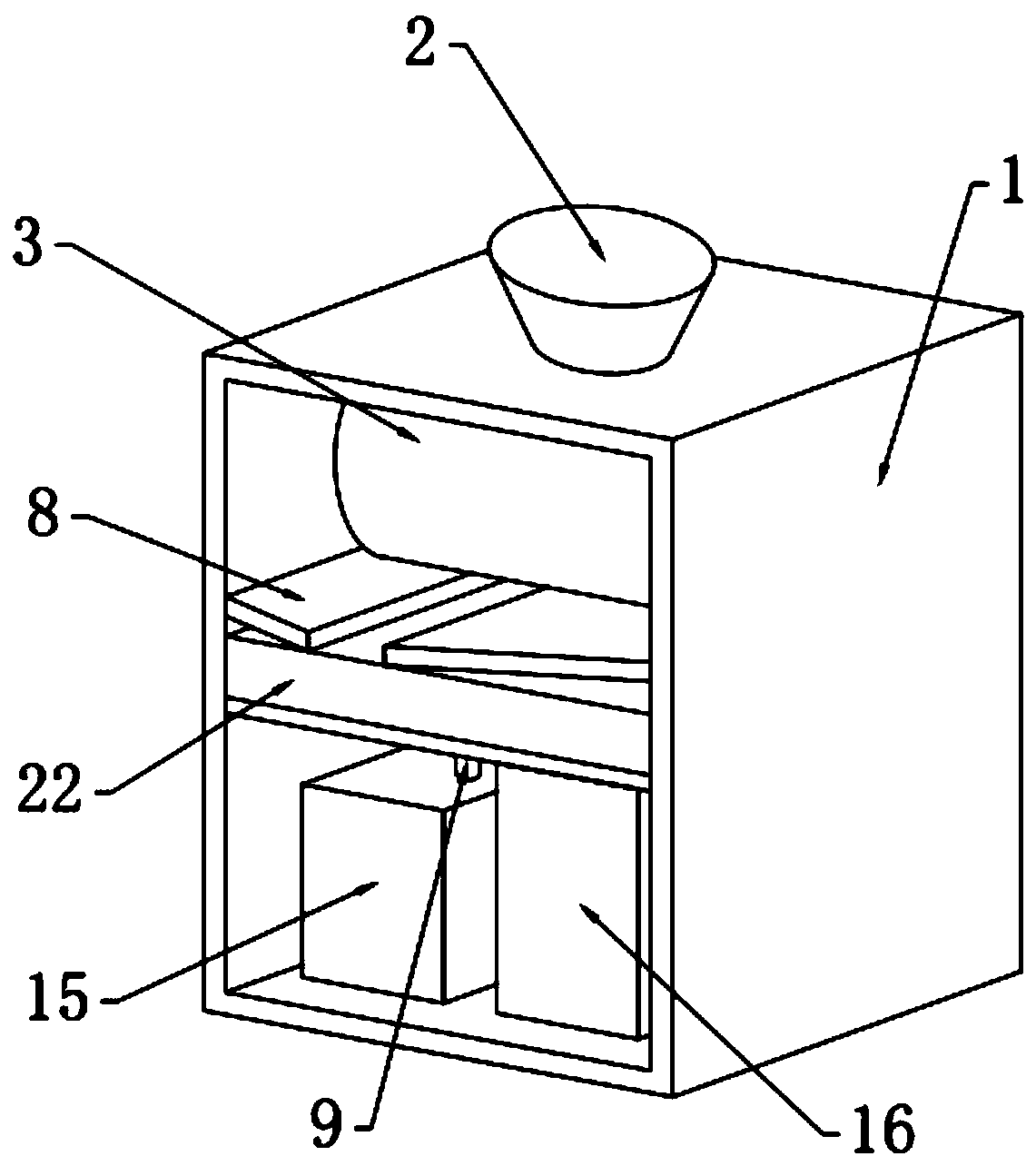

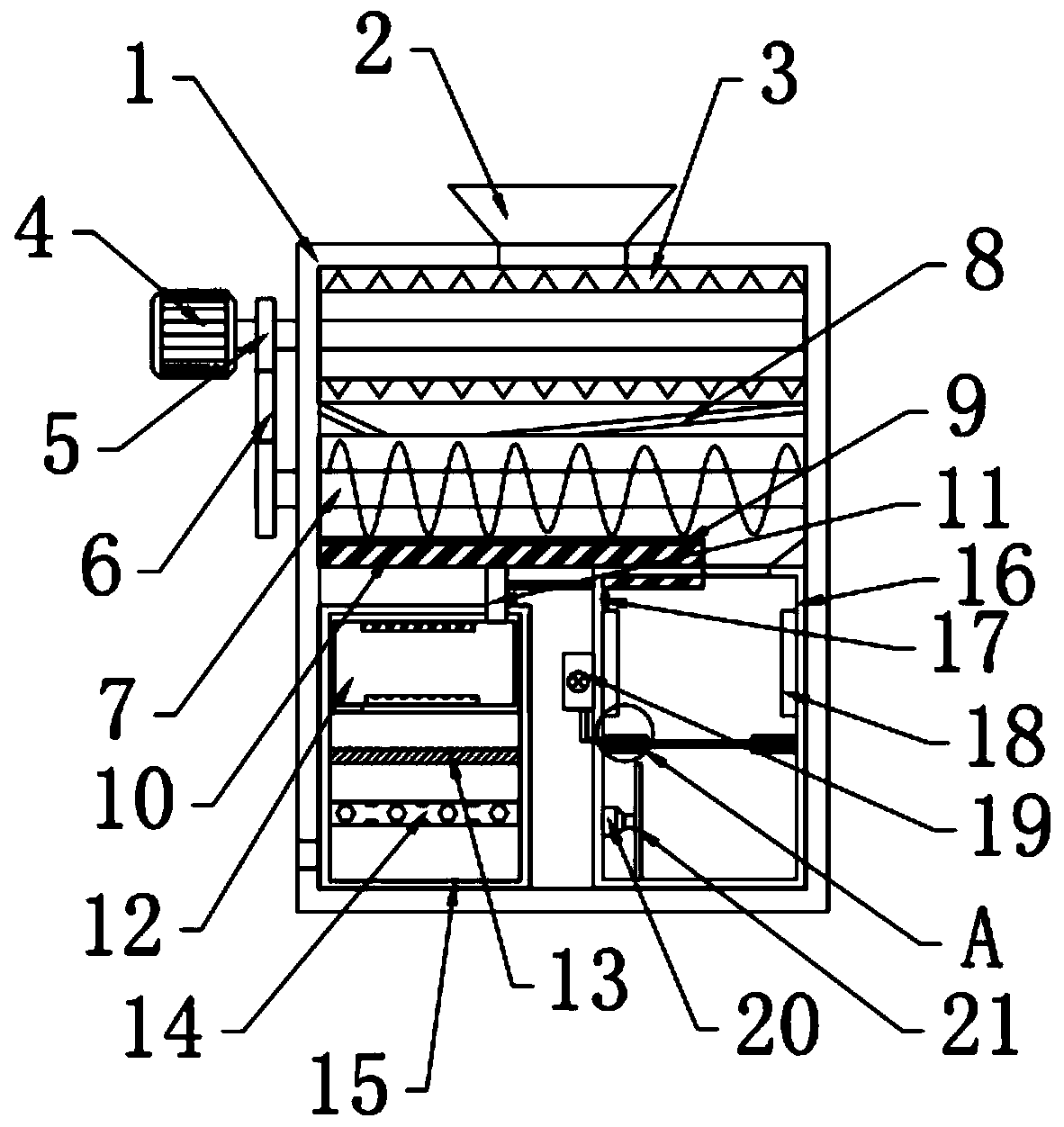

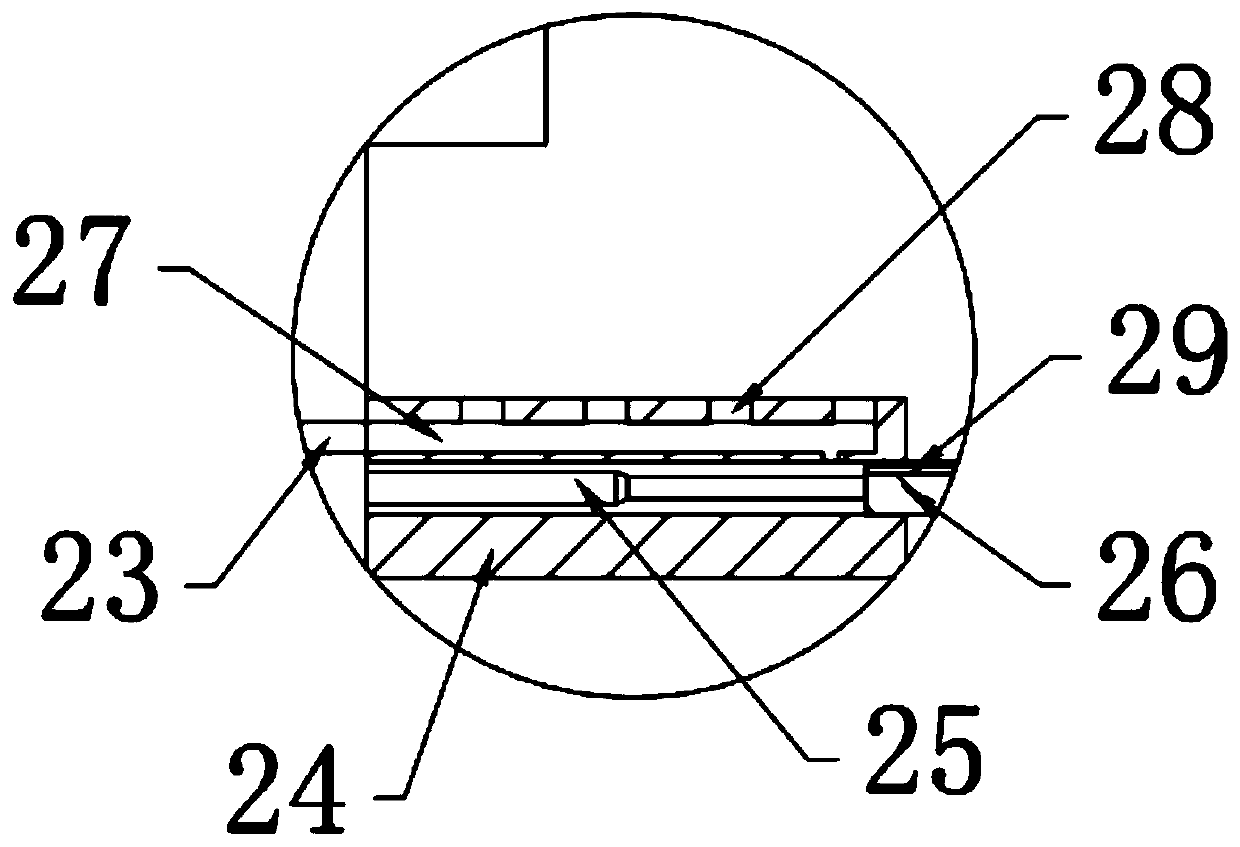

[0026] see Figure 1~3 , in the embodiment of the present invention, an environmentally friendly kitchen waste treatment device includes a casing 1, a feeding hopper 2 is arranged on the top of the casing 1, a crushing chamber 3 is arranged on the lower side of the feeding hopper 2, and the crushing A solid-liquid separation chamber 22 is arranged on the lower side of the chamber 3, and a guide plate 8 is arranged between the solid-liquid separation chamber 22 and the pulverization chamber 3, and a liquid treatment tank 15 is arranged on the lower side of the left end of the solid-liquid separation chamber 22. The liquid separation chamber 22 is connected to the liquid processing tank 15 through the water conduit 11, and the solid processing tank 16 is arranged on the right side of the liquid processing tank 15.

[0027] In this embodiment, a crushing roller is provided in the crushing chamber 3, and a motor 4 for driving the crushing roller is provided at the left end of the ...

Embodiment 2

[0034] A garbage treatment and recovery device, comprising the environment-friendly kitchen waste treatment device described in Embodiment 1.

[0035] In this environment-friendly kitchen waste treatment device, by setting the crushing chamber 3, the garbage can be crushed, and the liquid in the solid waste can flow out, which is convenient for solid-liquid separation. Liquid collection, by setting the liquid treatment box 15, the sewage can be disinfected, oil-water separation and water quality purification can also be realized, so that the discharged domestic wastewater is clean, the sewer has no odor, and the living environment is cleaner. The device 18 can effectively remove the moisture inside the solid waste, and process the kitchen waste into dry particles, which can be used as organic fertilizer. By setting the pressing plate 21 and the first telescopic rod 20, the dried solid waste can be compressed, It is convenient to store or discard the garbage. By setting the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com