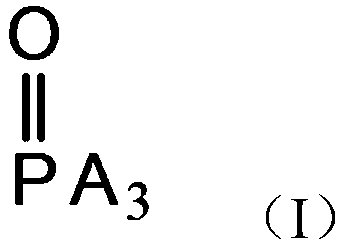

Lithium base grease and preparation method thereof

A lithium-based grease and grease technology, applied in the field of grease, can solve problems such as rare, polluted land, rivers and lakes, and poor biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

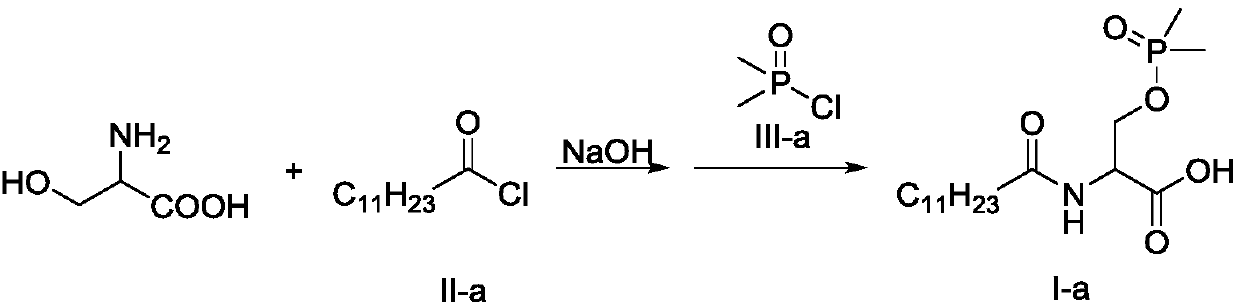

[0042] Embodiment 1, synthesis O-dimethylphosphono-N-dodecanoylserine (see structural formula I-a)

[0043]

[0044] 1) Add L-serine (47.6mmol, 5g), 40mL acetone, 20mL water, sodium hydroxide (95.2mmol, 10g) to the reactor in turn, cool down to 0°C, add lauroyl chloride dropwise (shown in formula II-a ) (47.6 mmol, 10.4 g). After reacting for 5 hours, use 6 mol / L hydrochloric acid solution to acidify to pH 2, a large amount of white solid appears, filter with suction, and wash the filter cake with water and petroleum ether.

[0045] 2) The above white solid (17.4mmol, 5g) was dissolved in 50mL of tetrahydrofuran, triethylamine (34.8mmol, 3.52g) was added, and dimethylphosphonyl chloride (shown in formula III-a) (17.4mmol , 1.96g), after reacting for 12 hours, use 6 mol / L hydrochloric acid solution to acidify to a pH value of 2, a large amount of white solids appear, filter with suction, wash the filter cake with water and petroleum ether, recrystallize from acetone to obta...

Embodiment 2

[0048] Embodiment 2, synthesis O-dimethylphosphono-N-heptadecanoylserine (see structural formula I-b)

[0049]

[0050] 1) Add L-serine (47.6mmol, 5g), 40mL acetone, 20mL water, sodium hydroxide (95.2mmol, 10g) to the reactor in sequence, drop the temperature to 0°C, add stearyl chloride (formula II-b) dropwise Shown) (47.6mmol, 14.4g). After reacting for 5 hours, use 6 mol / L hydrochloric acid solution to acidify to pH 2, a large amount of white solid appears, filter with suction, and wash the filter cake with water and petroleum ether.

[0051] 2) The above white solid (17.4mmol, 6.46g) was dissolved in 50mL of tetrahydrofuran, triethylamine (34.8mmol, 3.52g) was added, and dimethylphosphonyl chloride (shown in formula III-a) (17.4 mmol, 1.96g), after reacting for 12 hours, use 6 mol / L hydrochloric acid solution to acidify to a pH value of 2, a large amount of white solid appears, filter with suction, wash the filter cake with water and petroleum ether, recrystallize from...

Embodiment 3

[0054] Embodiment 3, synthesis O-dimethylphosphono-N-oleoylserine (see structural formula I-c)

[0055]

[0056] 1) Add L-serine (47.6mmol, 5g), 40mL acetone, 20mL water, sodium hydroxide (95.2mmol, 10g) to the reactor in sequence, cool down to 0°C, drop oleoyl chloride (shown in formula II-c) (47.6 mmol, 13.45 g). After reacting for 5 hours, use 6 mol / L hydrochloric acid solution to acidify to pH 2, a large amount of white solid appears, filter with suction, and wash the filter cake with water and petroleum ether.

[0057] 2) The above white solid (17.4mmol, 6.43g) was dissolved in 50mL of tetrahydrofuran, triethylamine (34.8mmol, 3.52g) was added, and dimethylphosphonyl chloride (shown in formula III-a) (17.4 mmol, 1.96g), after reacting for 12 hours, use 6 mol / L hydrochloric acid solution to acidify to a pH value of 2, a large amount of white solid appears, filter with suction, wash the filter cake with water and petroleum ether, recrystallize from acetone to obtain O-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com