Cone-shaped hyperbolic metamaterial photonic structure and preparation method thereof

A photonic structure and cone-shaped technology, which is applied in the field of metamaterial photonic devices, can solve the problems of dependence, long time-consuming ion beam etching, and inability to apply in large areas, and achieve good anti-reflection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

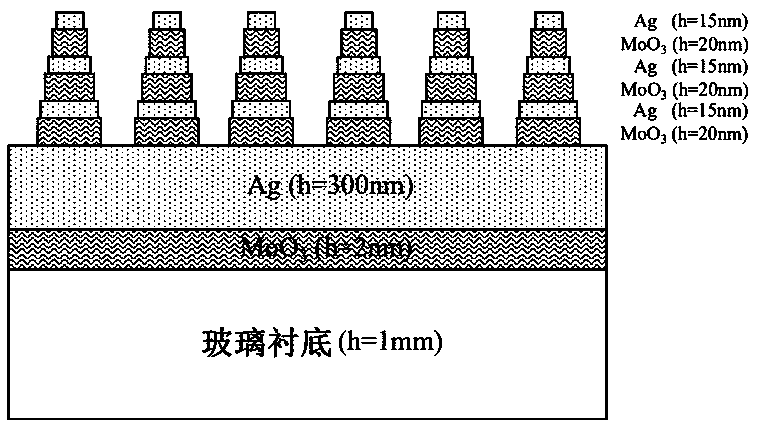

[0020] The materials used in the present invention have:

[0021] Molybdenum trioxide (MoO 3 ), silver (Ag), ultra-thin two-way anodized aluminum oxide (AAO), glass sheet, acetone, ethanol, isopropanol, deionized water, sodium dodecyl sulfate (SDS), Liby detergent (composed of demineralized water, Surfactant, Vitamin E Esters, Lemon Extract), Nitrogen, Adhesive Tape.

[0022] Its combined dosage is as follows:

[0023] Molybdenum trioxide: MoO 3 1g±0.01g

[0024] Silver: Ag 10g±0.01g

[0025] Deionized water: H 2 O 2000ml±50ml

[0026] Sodium dodecyl sulfate (SDS): 1±0.5 g

[0027] Detergent: 2±0.5 ml

[0028] Acetone: CH 3 COCH 3 60ml±5ml

[0029] Ethanol: 250ml

[0030] Isopropanol: 250ml

[0031] Slide: 12mm×12mm×1mm

[0032] Ultra-thin double-pass anodized aluminum film: area 3 mm×3 mm

[0033] The specific preparation method is as follows:

[0034] (1) Selected chemical substances

[0035] The chemical substances and materials required for preparation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com