Oxygen reduction catalyst layer based on polyionic liquid as proton conductor and preparation method of oxygen reduction catalyst layer

A technology of polyionic liquid and proton conductor, which is applied in the field of oxygen reduction catalytic layer and its preparation, can solve the problems of greenhouse effect, environment and pollution, and achieve the effects of enhancing transmission performance, suppressing coverage, and excellent oxygen reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

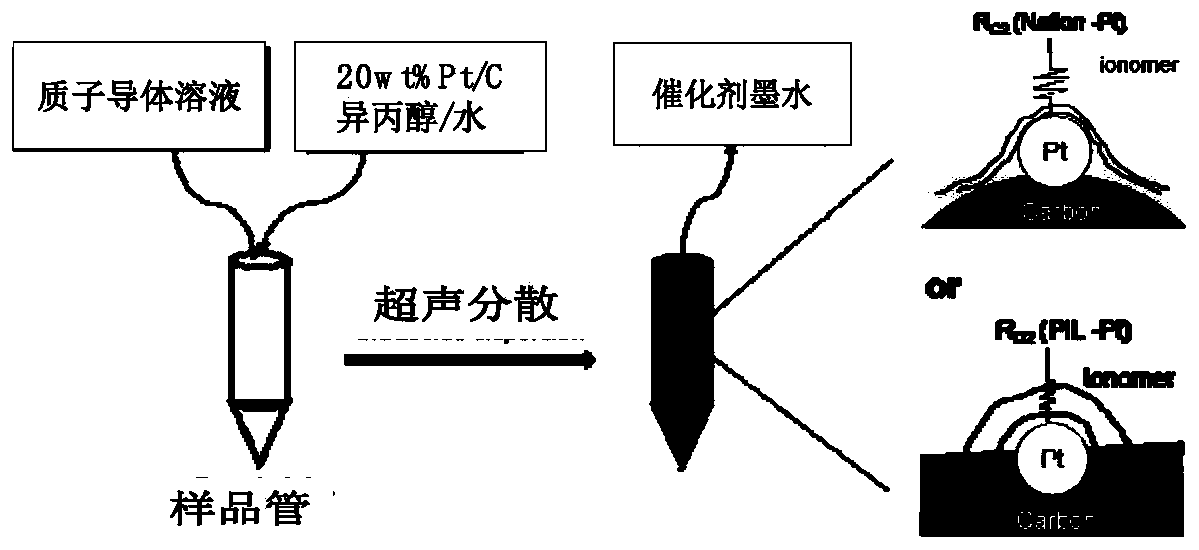

[0037] A novel fuel cell oxygen reduction catalytic layer based on a polyionic liquid proton conductor and a preparation method thereof, comprising the following steps:

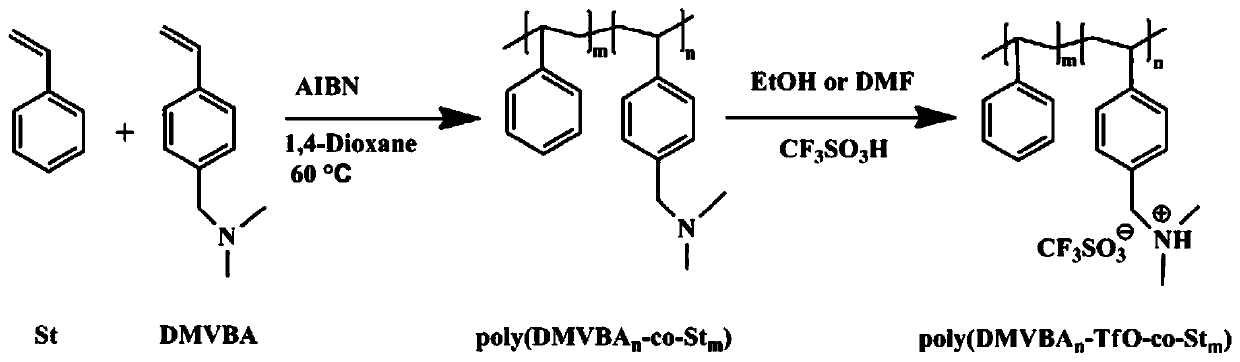

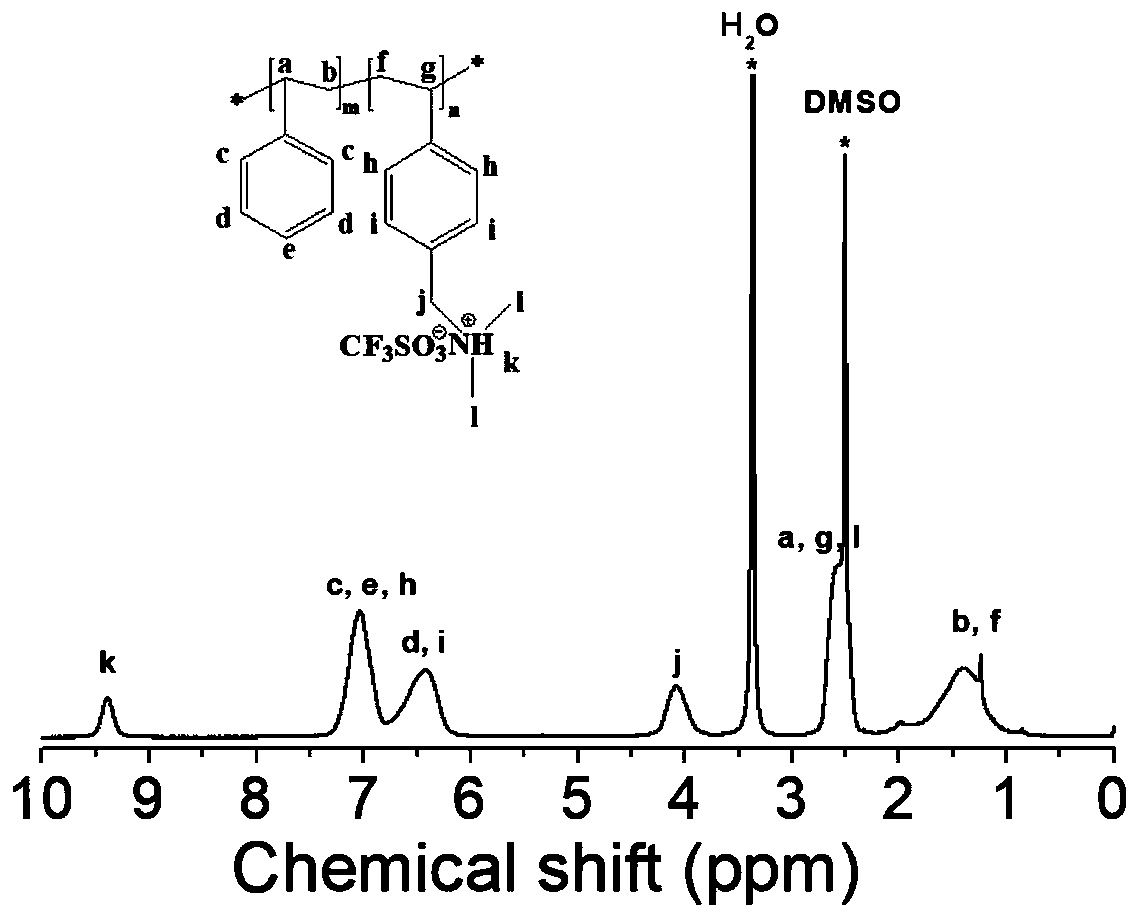

[0038] (1) Preparation of copolymer precursor: under the protection of nitrogen, add 2.7mL of anhydrous 1,4-dioxane to the reaction flask, with styrene:N,N-dimethylvinylbenzylamine moles Add 1.51g of styrene and 1.0g of N,N-dimethylvinylbenzylamine in sequence at a ratio of 7:3, the monomer volume concentration is 50%, and then add 0.8% of azobisisobutyronitrile by monomer mass 0.02g. After stirring evenly, after 3 cycles of freezing-vacuumizing-thawing to remove residual oxygen in the reaction bottle, then place the reaction bottle in an oil bath at 60±1°C for free radical copolymerization for 24 hours. After the reaction, put the product in a large amount of frozen ethanol Precipitate in a mixed solvent with a volume ratio of 1 / 4 of deionized water, and wash for several times, and then vacuum-dry the washe...

Embodiment 2

[0042] Experimental procedure is identical with embodiment 1, and difference is: the massfraction of the proton type polyionic liquid copolymer solution used in the configuration of catalyst ink in step (3) is 5Wt%, the electrochemical performance of the novel catalytic layer prepared The active area is 81.17m 2 / g, the proton impedance is 1.47Ωcm 2 , the coverage of inactive oxides on the platinum surface was 24.74%.

Embodiment 3

[0044] Experimental procedure is identical with embodiment 1, and difference is: the massfraction of the proton type polyionic liquid copolymer solution used in the configuration of catalyst ink in the step (3) is 8Wt%, the electrochemical performance of the novel catalytic layer prepared The active area is 79.65m 2 / g, the proton impedance is 1.36Ωcm 2 , the coverage of inactive oxides on the platinum surface was 27.92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active area | aaaaa | aaaaa |

| Active area | aaaaa | aaaaa |

| Electrochemically active area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com