Extinction label film and preparation method thereof, and transparent label film preparation method

A labeling and matting technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of matting performance, poor printing performance and strength, complex processing steps, etc., achieve good gloss, avoid Silver dot defect, the effect of reducing the reflection of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

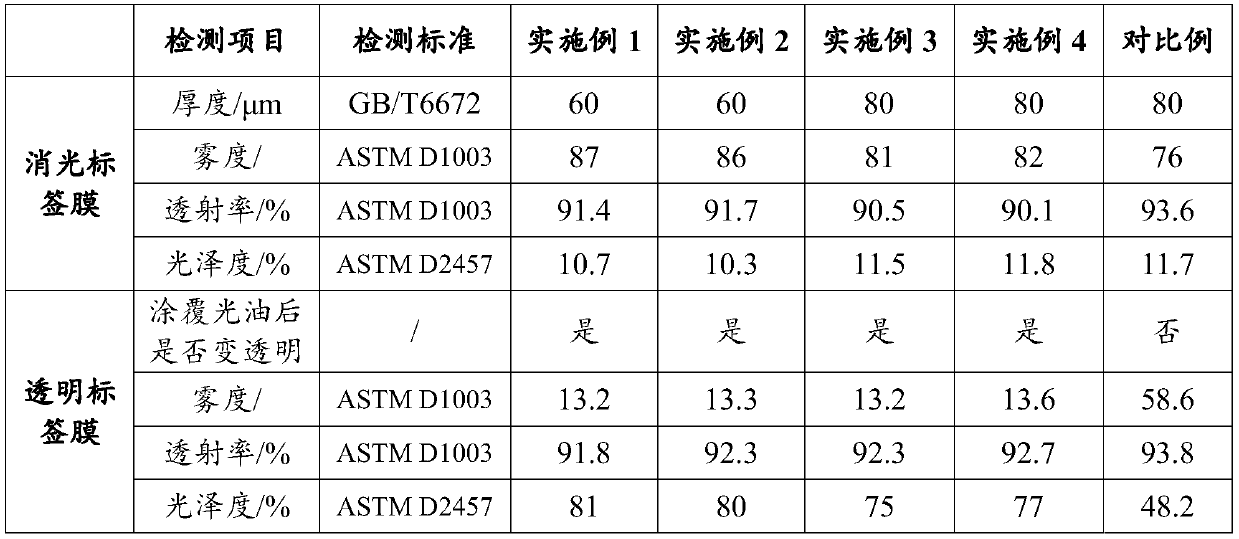

Examples

preparation example Construction

[0026] The present invention proposes a preparation method of a matte label film, comprising the following steps:

[0027] Dust removal: After mixing the raw materials of the outer layer, middle layer and inner layer evenly, use compressed air to remove dust;

[0028] Extrusion and plasticization: Add the dust-removed outer layer, middle layer and inner layer raw materials to the feed end of the single-screw extruder respectively, melt and plasticize, and cast and extrude through the co-extrusion die to obtain a composite melt;

[0029] Cooling and shaping: the composite melt is transported to the embossing roller group, rapidly cooled and shaped to form a composite film;

[0030] Trimming and corona treatment: importing the composite film into a trimming machine, trimming the composite film, and then performing corona treatment on the composite film after trimming;

[0031] Hemming: The corona-treated composite film is introduced into a winder, and the matte label film is ob...

Embodiment 1

[0051] Dust removal: Weigh 60% low-density polyethylene, 8% maleic anhydride graft modified polyethylene and 32% high-density polyethylene as raw materials for the outer layer, and weigh 38% low-density polyethylene and 62% high-density polyethylene as raw materials for the inner layer. % high-density polyethylene, weigh 100% high-density polyethylene middle layer raw material, weigh 100% high-density polyethylene middle layer raw material, mix the outer layer raw material, middle layer raw material and inner layer raw material respectively, Use compressed air to remove dust, and dry the dust-removed outer layer raw materials, middle layer raw materials and inner layer raw materials respectively. The drying time is 60 minutes and the drying temperature is 80 °C;

[0052] Extrusion and plasticization: add the dust-removed outer layer raw materials, middle layer raw materials and inner layer raw materials to the feed ends of three single-screw extruders, melt and plasticize them,...

Embodiment 2

[0057] Dust removal: Weigh 65% low-density polyethylene, 5% metallocene linear low-density polyethylene and 30% high-density polyethylene for the outer layer, weigh 40% low-density polyethylene and 60% High-density polyethylene, take the intermediate layer raw material of 100% high-density polyethylene, mix the outer layer raw material, the middle layer raw material and the inner layer raw material respectively, and use compressed air to carry out dust removal treatment on it, and the outer layer material after dust removal treatment Layer raw materials, middle layer raw materials and inner layer raw materials are dried separately, the drying time is 60min, and the drying temperature is 80°C;

[0058] Extrusion and plasticization: add the dust-removed outer layer raw materials, middle layer raw materials and inner layer raw materials to the feed ends of three single-screw extruders, melt and plasticize them, and then cast and extrude them through a co-extrusion die to obtain C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com