Method for preparing and drying magnesium trisilicate

A drying method and technology of magnesium trisilicate, applied in the direction of magnesium silicate, silicate, separation method, etc., can solve the problems of complex process operation, not conforming to the feeling of no sand, and large product particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

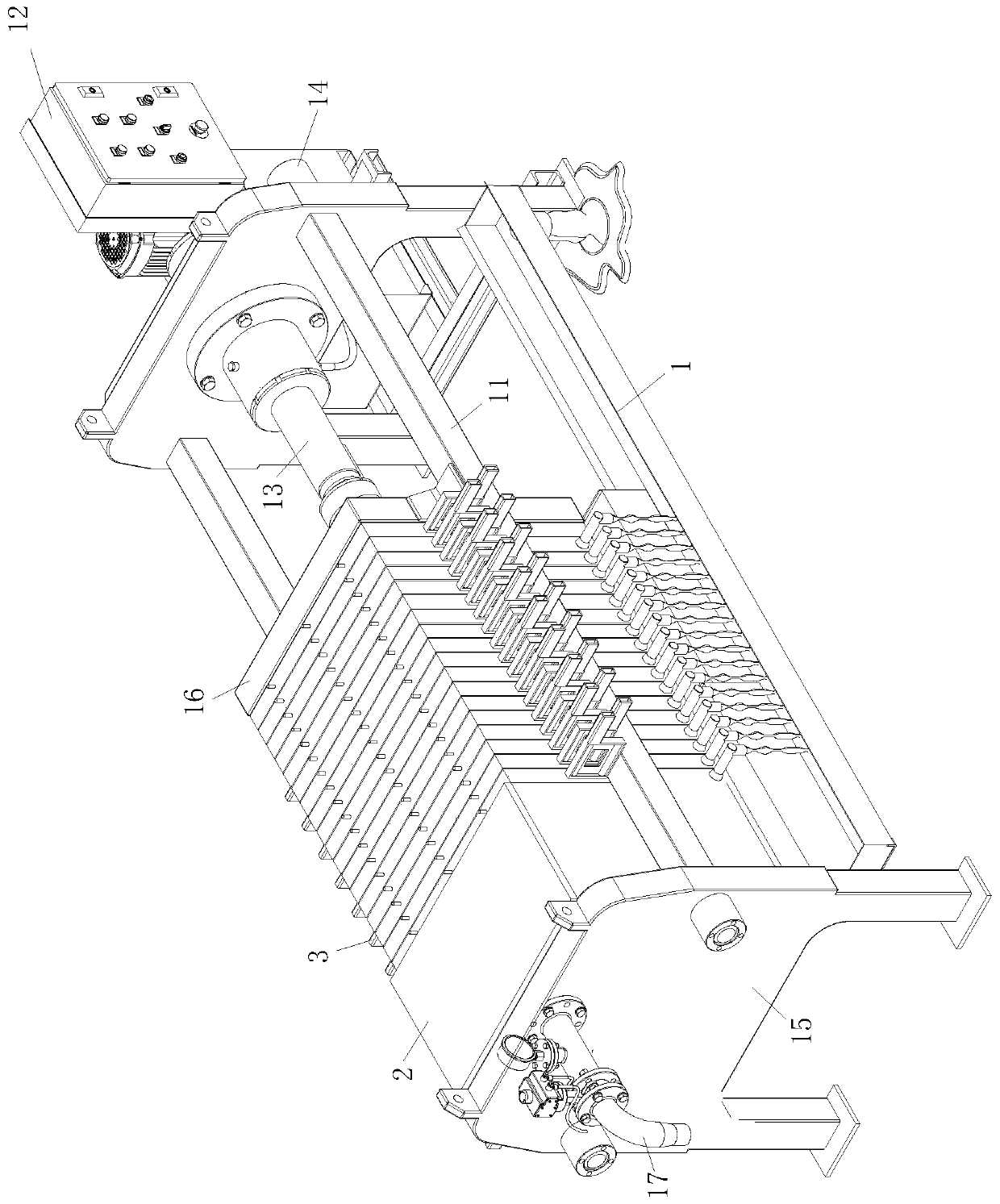

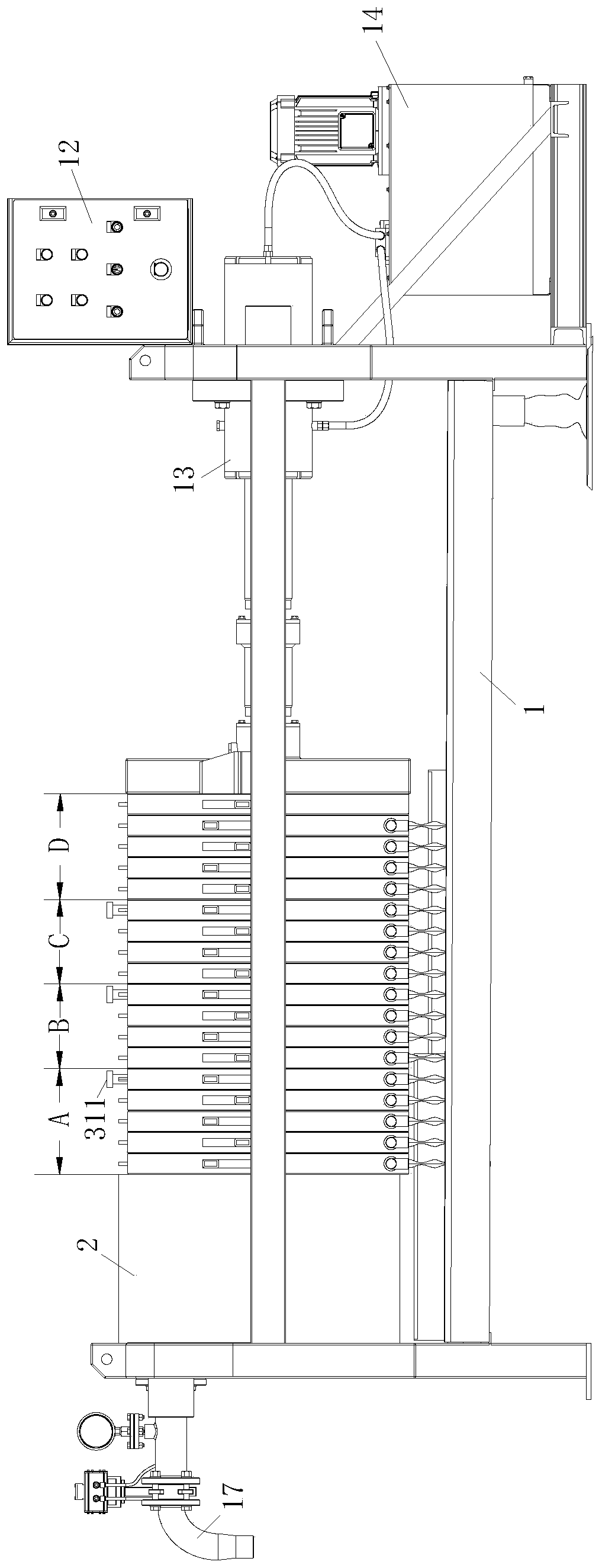

[0054] according to Figure 1-Figure 8 , the preparation and drying method of a kind of magnesium trisilicate according to the embodiment of the present invention are explained as follows:

[0055] The preparation and drying method of described a kind of magnesium trisilicate, described preparation and drying method steps are as follows:

[0056] S1. Store a certain amount of boiler scale through a large number of recycling methods; take 1000-1500 parts of boiler scale, pre-treat the selected boiler scale, including screening, drying, and then crush it to 3-5cm pellets, and put it into In the ultrafine grinding equipment, until it is ultrafinely pulverized to a size of 100 mesh, boiler scale powder is formed, and the powdery form is convenient for better chemical reactions; because the highest component of boiler scale is CaCO 3 , the second component is Mg(OH) 2 , so taking as much boiler scale as possible helps to extract more MgSO 4 Magnesium salt is prepared and used; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com