Low-temperature resistant tile stone backing adhesive and preparation method thereof

A technology of low temperature resistance and ceramic tiles, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of vitrified tiles falling off, falling off, and uneven quality, and achieve high tensile strength, good cold resistance, and adhesion Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

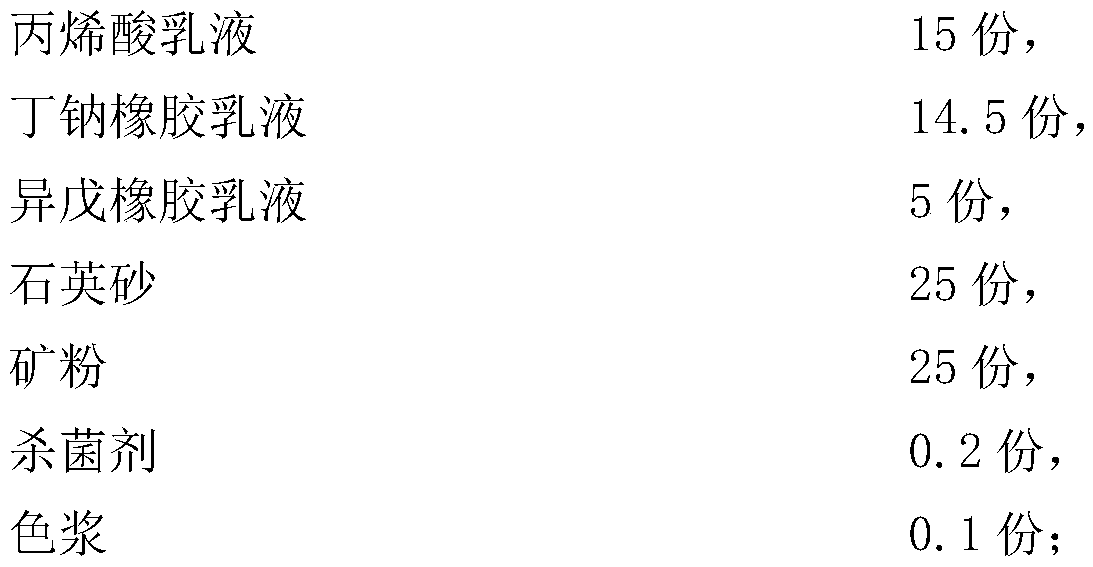

[0018] A low-temperature-resistant ceramic tile and stone adhesive, the raw material composition of which includes:

[0019]

[0020] Wherein, in parts by weight, the Buna rubber emulsion is made of 7.5 parts of Buna rubber and 7 parts of toluene; the isoprene rubber emulsion is made of 3.5 parts of Isoamyl rubber and 1.5 parts of butane.

[0021] The mesh number of the quartz sand is 40 mesh; the color paste is medium yellow paste.

[0022] A method for preparing low-temperature-resistant ceramic tile and stone back glue, comprising the following steps:

[0023] 1) drop sodium-butadiene rubber and toluene into a reactor to prepare sodium-butadiene rubber emulsion;

[0024] 2) putting isoprene rubber and butane into the reactor to prepare isoprene rubber emulsion;

[0025] 3) Put acrylic acid emulsion, butadiene rubber emulsion, and isoprene rubber emulsion into a disperser and stir for 25 minutes to obtain a mixed emulsion, and the rotating speed of the disperser is 800 ...

Embodiment 2

[0028] A low-temperature-resistant ceramic tile and stone adhesive, the raw material composition of which includes:

[0029]

[0030] Wherein, in parts by weight, the buna rubber emulsion is made of 8 parts of buna rubber and 7.5 parts of toluene; the isoprene rubber emulsion is made of 4 parts of isoprene rubber and 2 parts of butane.

[0031] The mesh number of the quartz sand is 50 mesh; the color paste is medium yellow paste.

[0032] A method for preparing low-temperature-resistant ceramic tile and stone back glue, comprising the following steps:

[0033] 1) drop sodium-butadiene rubber and toluene into a reactor to prepare sodium-butadiene rubber emulsion;

[0034] 2) putting isoprene rubber and butane into the reactor to prepare isoprene rubber emulsion;

[0035] 3) Put acrylic acid emulsion, butadiene rubber emulsion, and isoprene rubber emulsion into a disperser and stir for 30 minutes to obtain a mixed emulsion, and the rotating speed of the disperser is 850 rpm...

Embodiment 3

[0038] A low-temperature-resistant ceramic tile and stone adhesive, the raw material composition of which includes:

[0039]

[0040] Wherein, in parts by weight, the buna rubber emulsion is made of 8.5 parts of buna rubber and 8 parts of toluene; the isoprene rubber emulsion is made of 4.5 parts of isoprene rubber and 2.5 parts of butane.

[0041] The mesh number of the quartz sand is 60 mesh; the color paste is medium yellow paste.

[0042] A method for preparing low-temperature-resistant ceramic tile and stone back glue, comprising the following steps:

[0043] 1) drop sodium-butadiene rubber and toluene into a reactor to prepare sodium-butadiene rubber emulsion;

[0044] 2) putting isoprene rubber and butane into the reactor to prepare isoprene rubber emulsion;

[0045] 3) Put acrylic acid emulsion, butadiene rubber emulsion, and isoprene rubber emulsion into a disperser and stir for 35 minutes to obtain a mixed emulsion, and the rotating speed of the disperser is 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com