A natural gas low nitrogen oxide vortex dispersion burner

A low-nitrogen oxide, diffuse combustion technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of low tail flue gas temperature, fan failure, etc., to reduce combustion temperature, reduce burnout time, The effect of raising the temperature of natural gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

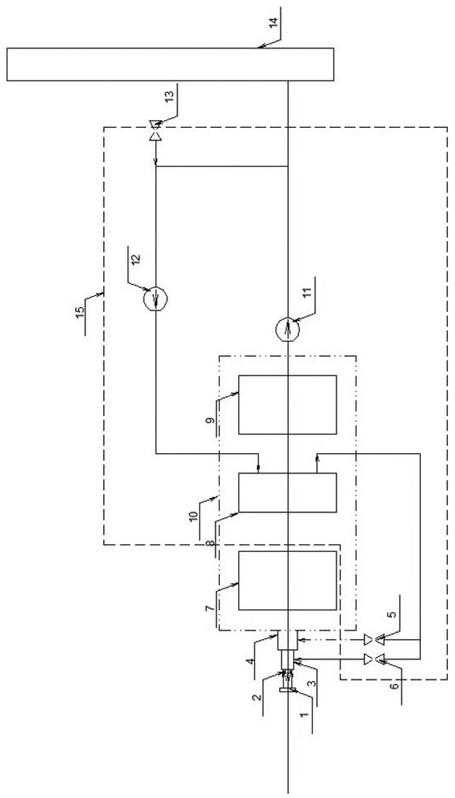

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 The shown natural gas pressure equalization chamber (1) is connected with an ignition chamber (2), and the ignition chamber (2) is connected with the first-stage swirl pre-combustion chamber (3), and the first-stage swirl pre-combustion chamber (3) ) is connected to the second-stage swirl pre-combustion chamber (4) at the rear, and the diameter of the second-stage swirl pre-combustion chamber should be greater than the diameter of the first-stage swirl pre-combustion chamber; the gas boiler (10) includes a boiler furnace (7 ), flue gas reheater (8), convection and tail heating surface (9); said second-stage swirl pre-combustion chamber (4) is directly connected with the boiler furnace (7) of gas boiler (10); said The front of the flue gas reheater (8) is connected to the boiler furnace (7), and the rear is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com