Multi-quantum well structure, and LED epitaxial wafer and preparation method thereof

A technology of multi-quantum well structure and LED epitaxial wafer, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of reducing internal quantum efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

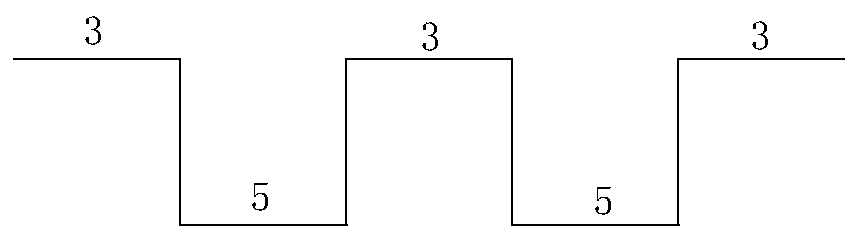

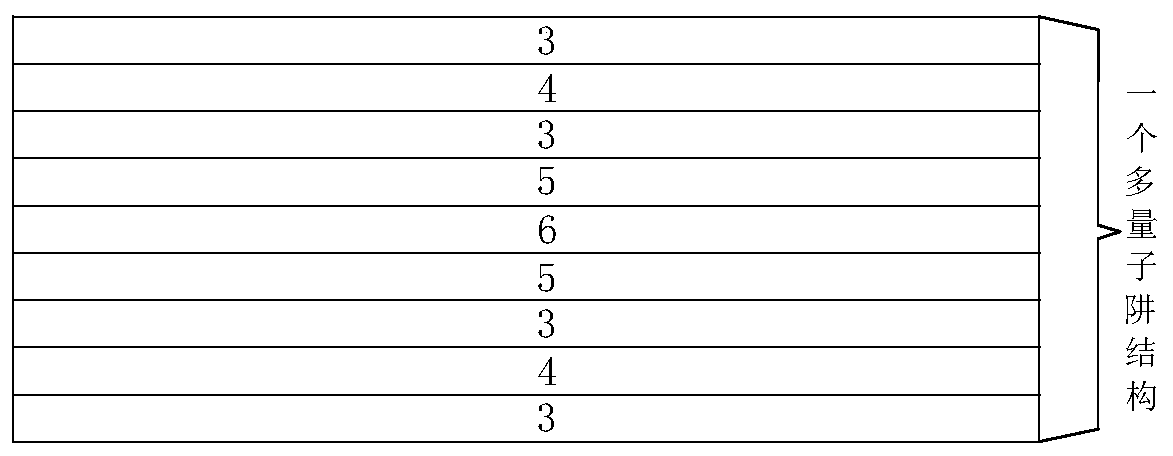

[0044] Embodiment 1, a multi-quantum well structure, is a 9-layer upper and lower layer superposition structure, and the 9 layers are grown sequentially from bottom to top;

[0045] The first layer is GaN barrier layer 3, the second layer is AlGaN barrier layer 4, the third layer is GaN barrier layer 3, the fourth layer is InGaN potential well layer 5, and the fifth layer is low-temperature InGaN potential well layer 6 , the sixth layer is an InGaN potential well layer 5, the seventh layer is a GaN barrier layer 3, the eighth layer is an AlGaN barrier layer 4, and the ninth layer is a GaN barrier layer 3;

[0046] The first layer, the second layer, the third layer, the fourth layer, the fifth layer, the sixth layer, the seventh layer, the eighth layer, and the ninth layer are stacked in order from bottom to top.

Embodiment 2

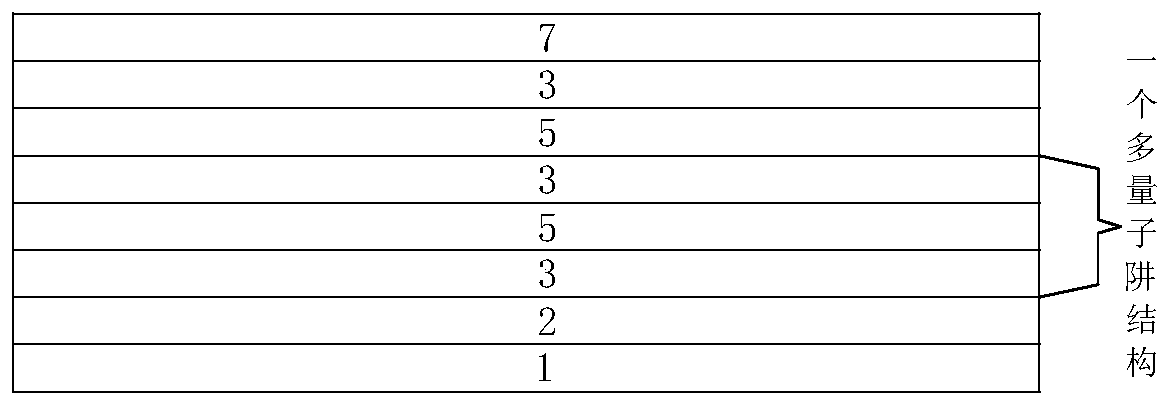

[0047] Embodiment 2, an LED epitaxial wafer, including a substrate 1, an N-type layer 2, 5-9 multi-quantum well structures and a P-type layer 7, each of the 5-9 multi-quantum well structures Both are the multi-quantum well structure in the above-mentioned embodiment 1;

[0048] 5 to 9 multi-quantum well structures are stacked sequentially from bottom to top;

[0049] The substrate 1 , N-type layer 2 , 5-9 multi-quantum well structures, and P-type layer 7 are stacked and arranged sequentially from bottom to top.

Embodiment 3

[0050] Embodiment 3, a method for preparing the above-mentioned LED epitaxial wafer, comprising the following steps in sequence:

[0051] 1) growing an N-type layer 2 structure on the substrate 1;

[0052] 2) growing a multi-quantum well structure on the upper surface of the N-type layer 2;

[0053] The preparation method of the multiple quantum well structure comprises the following steps carried out in sequence:

[0054] a) growing a first layer on the upper surface of the N-type layer 2, the first layer being a GaN barrier layer 3;

[0055] b) growing a second layer on the upper surface of the first layer, the second layer being an AlGaN barrier layer 4;

[0056] c) growing a third layer on the upper surface of the second layer, the third layer being a GaN barrier layer 3;

[0057] d) growing a fourth layer on the upper surface of the third layer, the fourth layer being an InGaN potential well layer 5;

[0058] e) growing a fifth layer on the upper surface of the fourth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com