Circuit board manufacturing method capable of preventing ink spillover

A production method and circuit board technology, which is applied in the fields of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems of uneven copper thickness of circuit board expansion and contraction, shortening the process, etc., to optimize the process production process, shorten the process, save The effect of working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

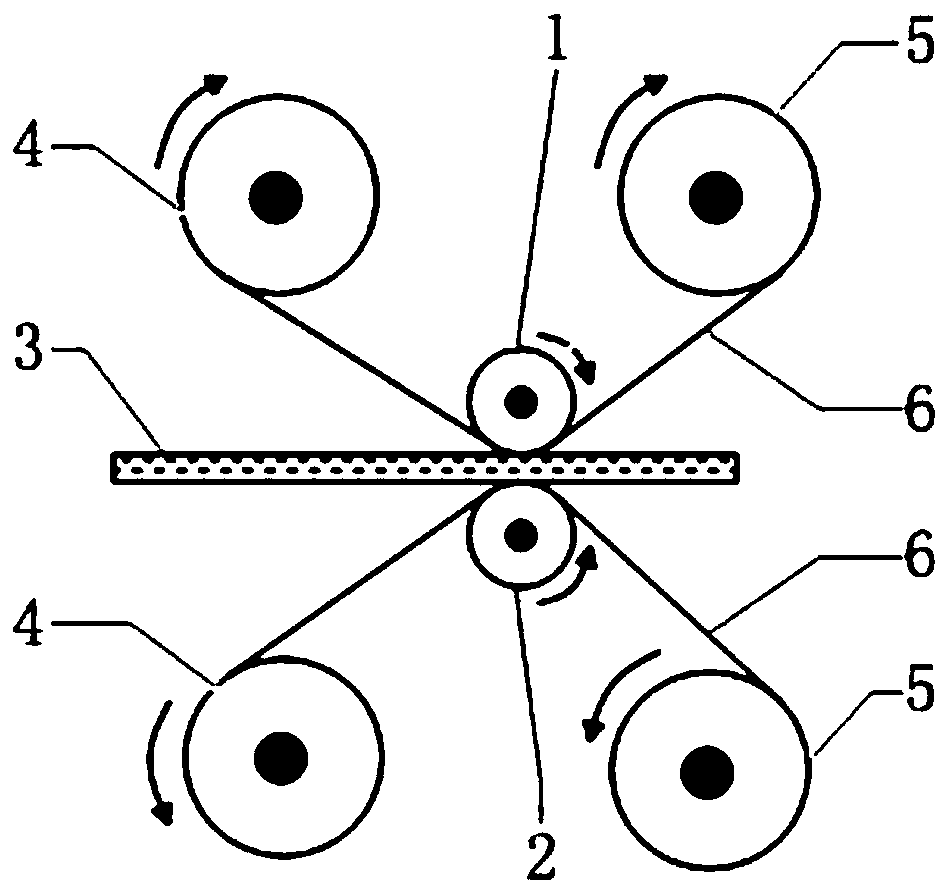

Image

Examples

Embodiment

[0030] This embodiment provides a method for manufacturing a circuit board to prevent ink spillage, and the specific process is as follows:

[0031] (1) Cutting: cut out the core board according to the board size 520mm×620mm, the thickness of the core board is 0.8mm, and the thickness of the outer layer of copper foil is 1OZ.

[0032] (2) Inner layer circuit production (negative film process): Inner layer graphics transfer, use a vertical coating machine to coat a photosensitive film on the core board, the film thickness of the photosensitive film is controlled at 8 μm, and a fully automatic exposure machine is used to 5-6 grids The exposure ruler (21-grid exposure ruler) completes the exposure of the inner layer circuit on the core board, and after development, the inner layer circuit pattern is formed on the core board; the inner layer is etched, and the inner layer circuit is etched out of the exposed and developed core board, and the inner layer The line width measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com