Preparation method for fermentation type piglet feed

A piglet feed and fermented technology, applied in the field of pig feed, can solve the problems of reducing diarrhea and improving piglet production performance at the same time, achieving the effect of reducing diarrhea, improving piglet production performance, and good comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

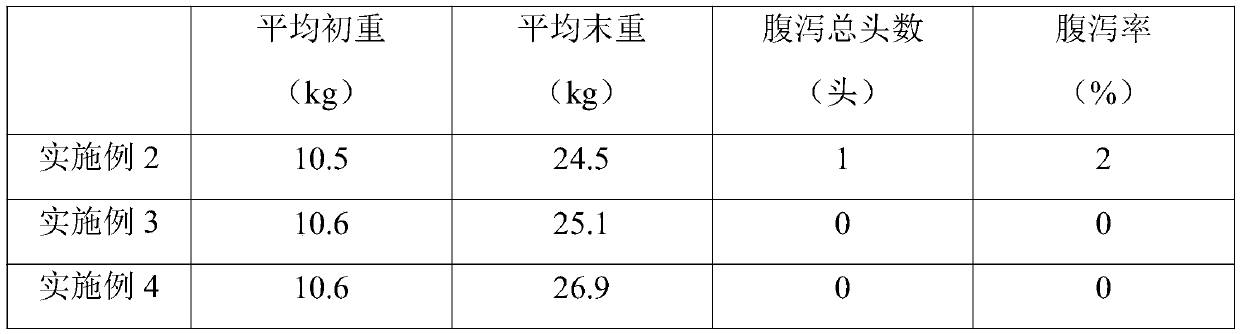

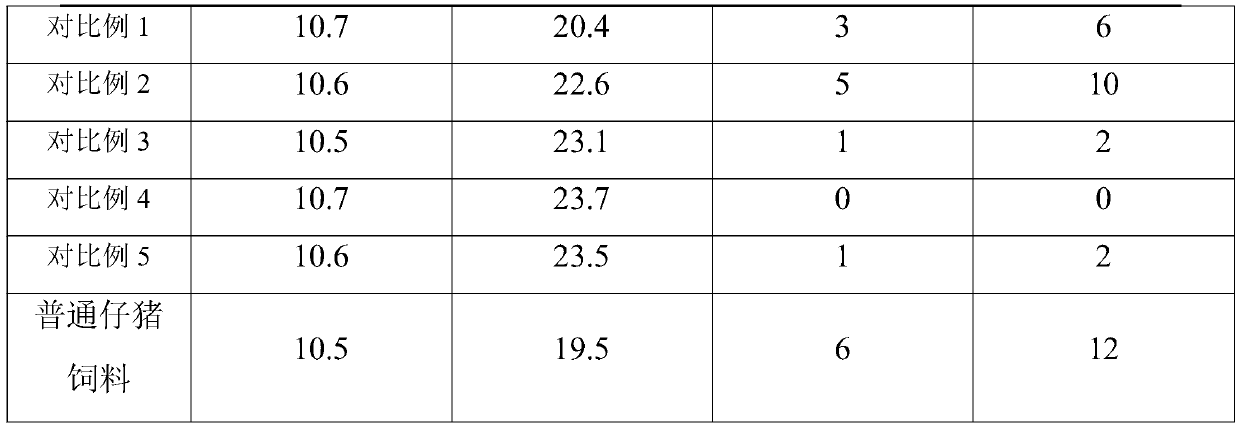

Examples

Embodiment 1

[0033] A preparation method for fermented piglet feed, comprising the following steps:

[0034] S1. Weigh the following raw materials in parts by weight: 45-55 parts of corn, 30-37 parts of soybean meal, 10-14 parts of rapeseed meal, 12-17 parts of wheat, 4-7 parts of peas, 4-6 parts of soybean oil, 5-8 parts of fish meal, 2-3 parts of sodium citrate, 1.4-1.8 parts of potassium citrate, 1.5-2.7 parts of calcium formate, 0.5-0.8 parts of lysine hydrochloride, 0.8-1.2 parts of vitamin premix, mineral premix 1 to 2 parts of mixture, 0.4 to 0.7 parts of antioxidant, 0.4 to 0.6 parts of antifungal agent, set aside;

[0035] S2. After mixing corn, soybean meal, rapeseed meal, wheat and peas, crushing; then adding water to stir and mix, and adjusting the water content to 40-50% to obtain a mixed material;

[0036] S3. Add microbial flora to the mixed material, mix evenly, send it into the fermentation room, and ferment it at 35-40°C for 2-3 days to obtain the preliminary fermentatio...

Embodiment 2

[0046] A preparation method for fermented piglet feed, comprising the following steps:

[0047] S1. Weigh the following raw materials in parts by weight: 45 parts of corn, 30 parts of soybean meal, 10 parts of rapeseed meal, 12 parts of wheat, 4 parts of pea, 4 parts of soybean oil, 5 parts of fish meal, 2 parts of sodium citrate, citric acid 1.4 parts of potassium, 1.5 parts of calcium formate, 0.5 parts of lysine hydrochloride, 0.8 parts of vitamin premix, 1 part of mineral premix, 0.4 part of antioxidant, 0.4 part of antifungal agent, spare;

[0048] S2, after mixing corn, soybean meal, rapeseed meal, wheat and peas, crushing; then adding water to stir and mix, adjusting to a water mass content of 40%, to obtain a mixed material;

[0049] S3, adding microbial flora to the mixed material, mixing evenly, sending it into a fermentation room, and fermenting at 35°C for 3 days to obtain a preliminary fermentation material; the added amount of the microbial flora is 1.2% of the w...

Embodiment 3

[0058] A preparation method for fermented piglet feed, comprising the following steps:

[0059] S1. Weigh the following raw materials in parts by weight: 55 parts of corn, 37 parts of soybean meal, 14 parts of rapeseed meal, 17 parts of wheat, 7 parts of pea, 6 parts of soybean oil, 8 parts of fish meal, 3 parts of sodium citrate, citric acid 1.8 parts of potassium, 2.7 parts of calcium formate, 0.8 parts of lysine hydrochloride, 1.2 parts of vitamin premix, 2 parts of mineral premix, 0.7 part of antioxidant, 0.6 part of antifungal agent, spare;

[0060] S2. After mixing corn, soybean meal, rapeseed meal, wheat and peas, crushing; then adding water and stirring and mixing, adjusting the water content to 50% to obtain a mixed material;

[0061] S3, adding microbial flora to the mixed material, mixing evenly, sending it into a fermentation room, and fermenting at 40°C for 2 days to obtain a preliminary fermentation material; the added amount of the microbial flora is 1.8% of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com