A kind of catalytic cracking anti-metal liquid enhancer and preparation method thereof

A catalytic cracking and anti-metal technology, applied in catalytic cracking, catalyst protection, chemical instruments and methods, etc., can solve problems such as easy to block pores and affect nickel resistance, improve reaction selectivity, reduce poisonous effects, and avoid catalysts The effect of the decrease in cracking activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

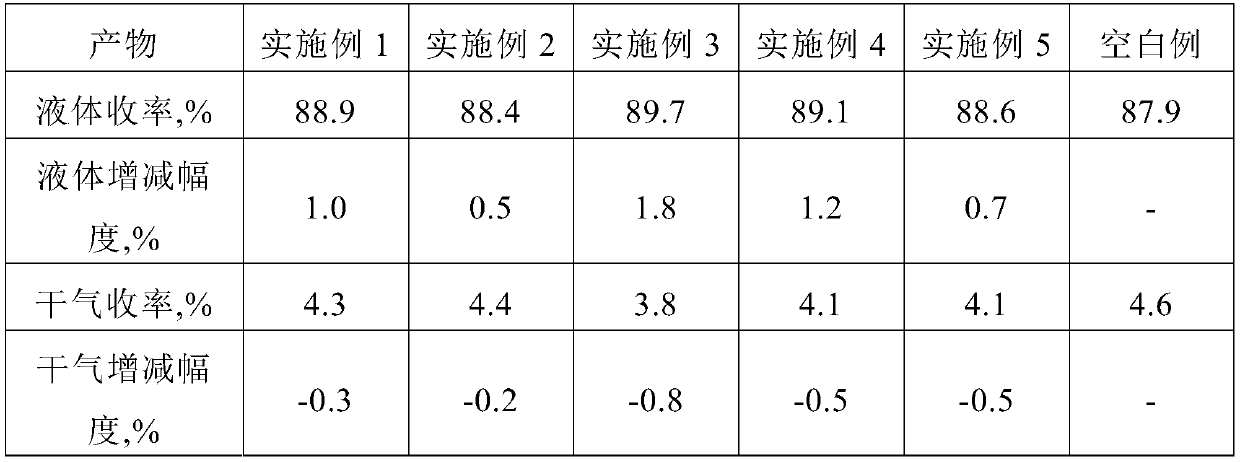

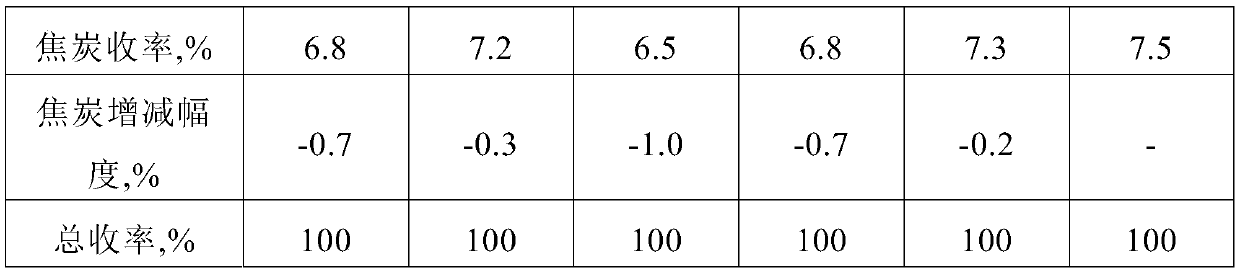

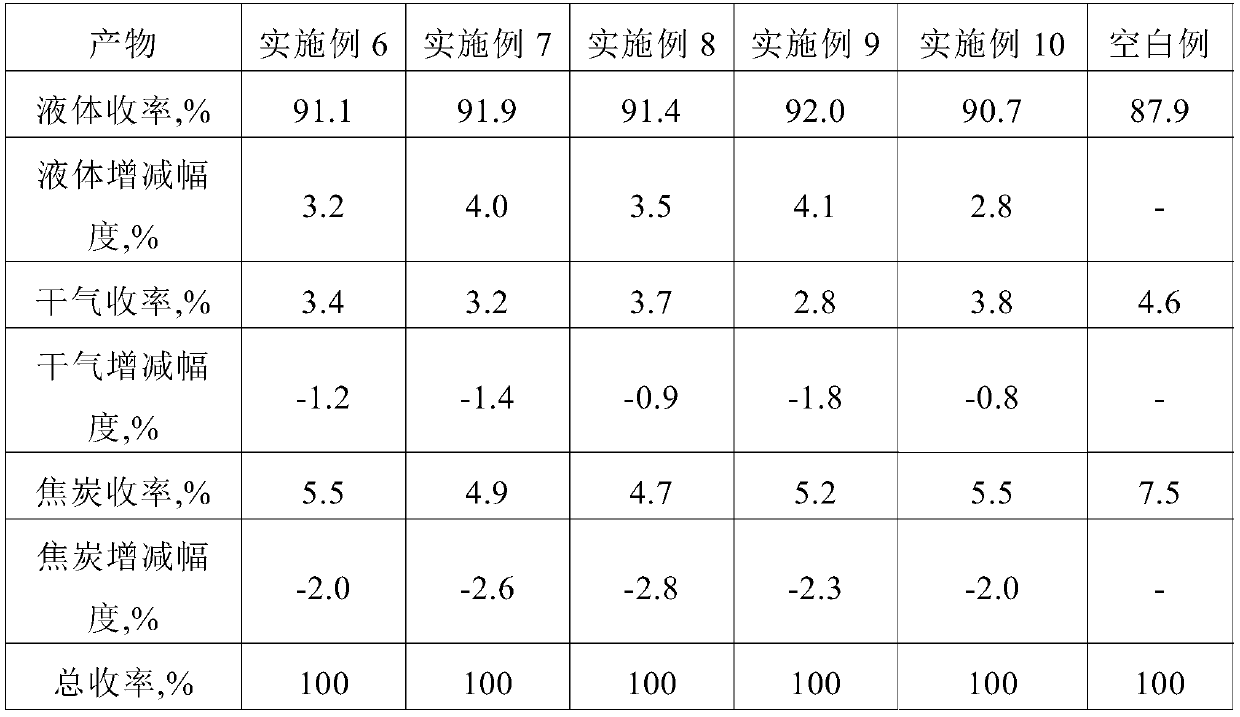

Examples

Embodiment 1

[0028] (1) Add 10 parts of antimony triacetate to 100 parts of ethanol and heat to 50°C to fully dissolve to form mixed solution A;

[0029] (2) Add 3 parts of rhodium silicotungstic heteropoly acid into mixed solution A and heat to 80°C to fully dissolve it to obtain mixed solution B;

[0030] (3) 87 parts of VPI-5 molecular sieves were added to the mixed solution B, continued to stir for 10 min at a speed of 2000 rpm, and then filtered to obtain a solid mixture;

[0031] (4) Dry the solid mixture at 130° C. for 10 minutes, and then put it into a muffle furnace at 560° C. and bake it for 30 minutes to obtain the FCC anti-metal liquid enhancer of the present invention.

Embodiment 2

[0033] (1) Add 0.5 parts of triphenylantimony to 100 parts of toluene to fully dissolve it to form a mixed solution A;

[0034] (2) Add 1.5 parts of ruthenium silicon tungsten heteropoly acid into the mixed solution A and heat it to 70°C to fully dissolve it to obtain the mixed solution B;

[0035] (3) 98 parts of the VPI-5 molecular sieves were added into the mixed solution B, and stirred for 30 min at a speed of 100 rpm, and then filtered to obtain a solid mixture;

[0036] (4) Dry the solid mixture at 100° C. for 30 minutes, then put it into a muffle furnace at 580° C. and bake it for 10 minutes to obtain the FCC anti-metal liquid enhancer of the present invention.

Embodiment 3

[0038] (1) Add 20 parts of antimony diisopropyl dithiophosphate into 100 parts of ethanol and heat to 80°C to fully dissolve it to form a mixed solution A;

[0039] (2) Add 10 parts of phosphotungstic dodecanopolyacid into the mixed solution A and heat it to 100°C to fully dissolve it to obtain the mixed solution B;

[0040] (3) 70 parts of the VPI-5 molecular sieves were added to the mixed solution B, continued to stir at a speed of 3600 rpm for 5 min, and then filtered to obtain a solid mixture;

[0041] (4) Dry the solid mixture at 90° C. for 50 minutes, and then put it into a muffle furnace at 480° C. and bake it for 50 minutes to obtain the FCC anti-metal liquid enhancer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com