Method for efficient and energy-saving sludge treatment

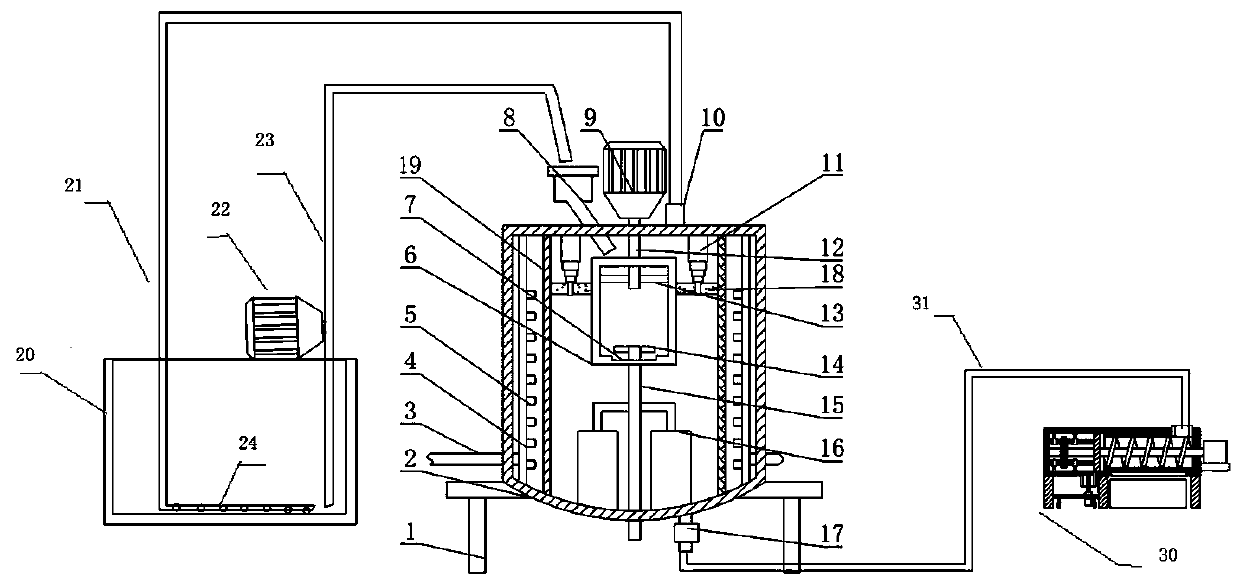

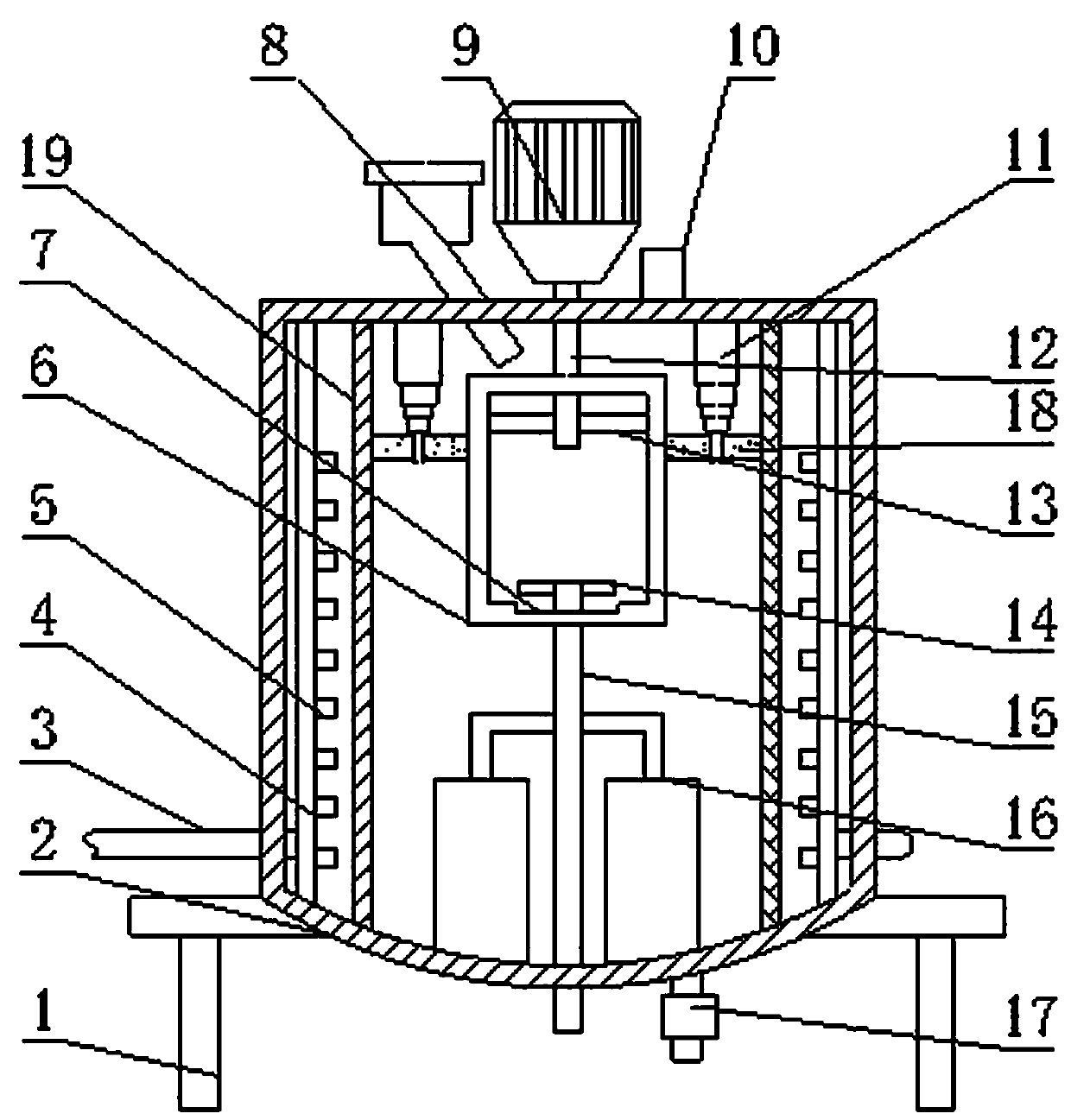

A technology for sludge treatment, high efficiency and energy saving, applied in sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc. It can solve the problems of about 60%, and achieve the effect of eliminating water hammer phenomenon, facilitating subsequent disposal, and reducing process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

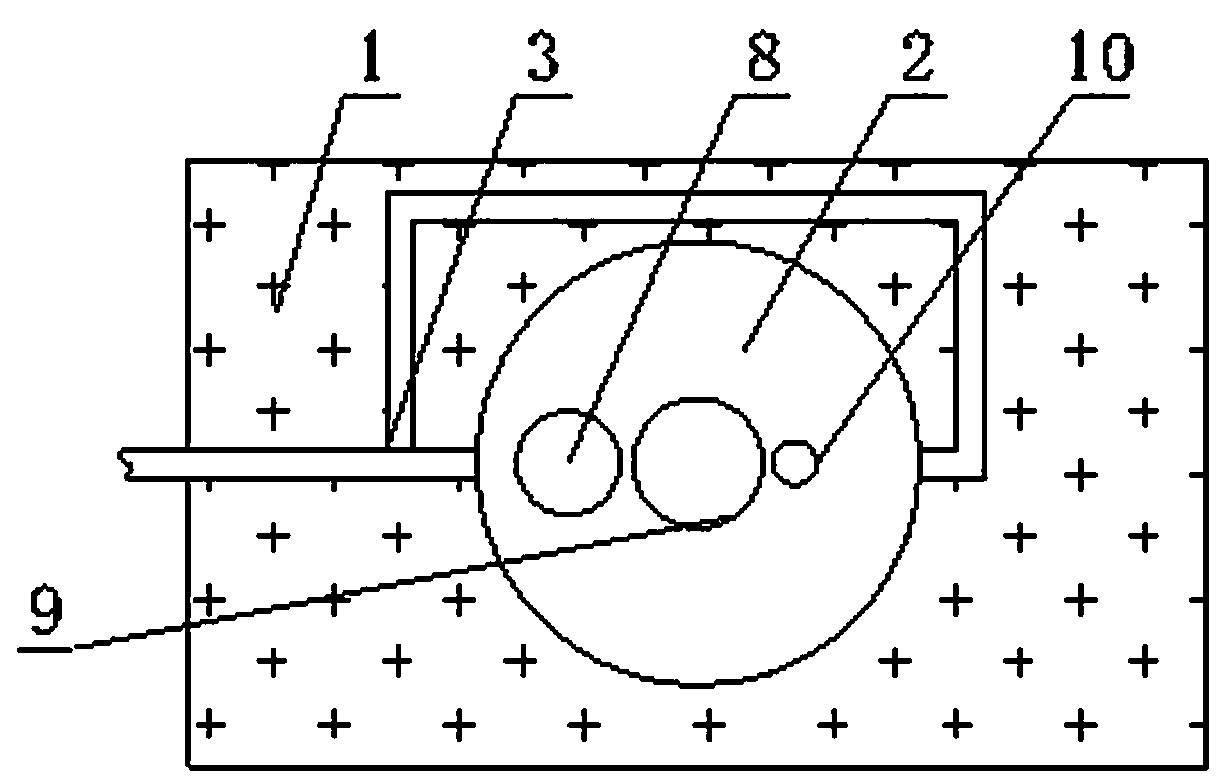

[0038] The sludge with a moisture content of 80% is first pumped to the preheating unit through a screw pump, and the screw pump is turned off when the mud reaches the set level. An aeration pipe is set in the preheating unit, and the aeration hole diameter is 1.8mm. The preheating of the mud is completed , The hot mud is pumped to the reactor through a pump. After the mud enters the reactor, the boiler provides continuous and stable high-pressure saturated steam (pressure 1.1-1.2Mpa) to the reactor to heat the sludge in the reactor and inject saturated steam 30 minutes, then stop the steam injection and keep it for 20 minutes; then open the pressure relief valve to start exhaust and pressure relief. The high-pressure steam discharged from the reactor enters the preheating unit through the aeration tube to fully preheat the raw mud to 60°C. The form forms a closed circuit. When the exhaust is completed, the discharge valve is opened to discharge the mud after thermal hydrolysis....

Embodiment 2

[0040] The sludge with a moisture content of 85% is first pumped to the preheating unit through a screw pump, and the screw pump is turned off when the mud reaches the set level. An aeration pipe is set in the preheating unit, and the aeration hole diameter is 2.5mm. The preheating of the mud is completed , The hot mud is pumped to the reactor through a pump. After the mud enters the reactor, the boiler provides continuous and stable high-pressure saturated steam (pressure 1.2-1.3Mpa) to the reactor to heat the sludge in the reactor and inject saturated steam After 25 minutes, stop the steam injection and keep it for 10 minutes; then open the pressure relief valve to start exhaust and pressure relief. The high-pressure steam discharged from the reactor enters the preheating unit through the aeration tube to fully preheat the raw mud to 65°C. The form forms a closed circuit. When the exhaust is completed, the discharge valve is opened to discharge the mud after thermal hydrolysis...

Embodiment 3

[0042] The sludge with a water content of 90% is first pumped to the preheating unit through a screw pump. When the mud reaches the set level, the screw pump is turned off. The preheating unit is equipped with an aeration pipe. After the preheating of the mud is completed, the hot mud is pumped to In the reactor, after the mud enters the reactor, the boiler provides continuous and stable high-pressure saturated steam (pressure 1.3-1.4Mpa) to the reactor, heats the sludge in the reactor, and injects saturated steam for 20 minutes, and then stops the steam injection. Hold for 10 minutes; then open the pressure relief valve to start exhaust and pressure relief. The high-pressure steam discharged from the reactor enters the preheating unit through the aeration tube to fully preheat the raw mud to over 70°C, forming a closed circuit in this way. At the end, open the discharge valve to discharge the thermally hydrolyzed mud. The mud in the preheating unit is pumped into the reactor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com