A kind of epoxy zinc-rich primer and preparation method thereof

A technology of epoxy zinc-rich primer and water-based epoxy resin, which is applied in the field of coatings, can solve problems such as uneven mixing and dispersion of zinc powder, reduction of paint film anti-corrosion performance, and influence of paint film appearance, so as to improve construction technology and curing performance Excellent, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

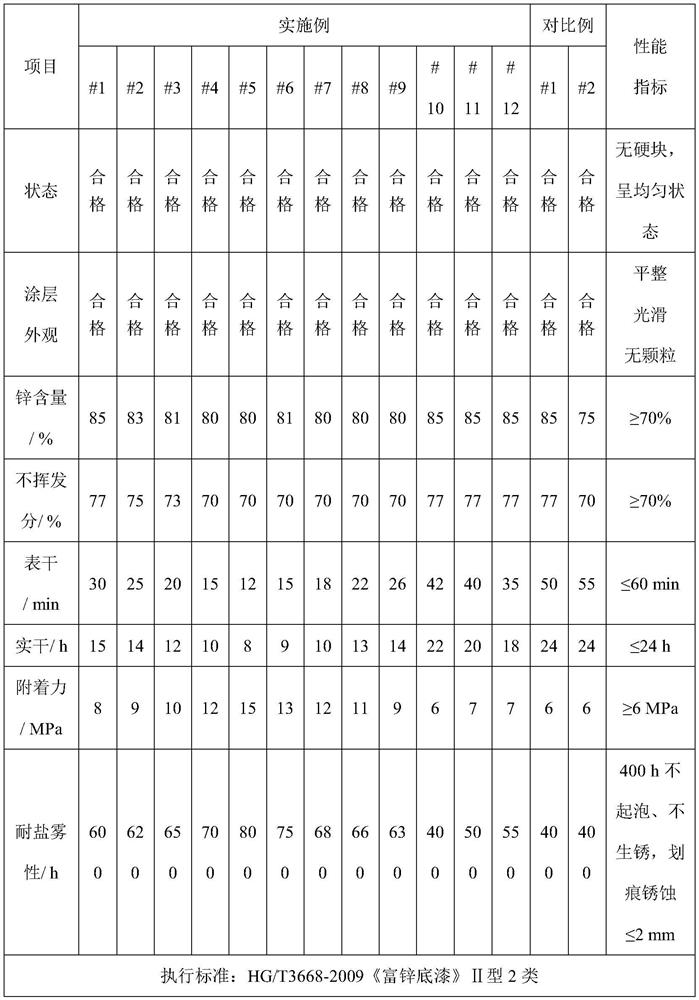

Examples

Embodiment 1

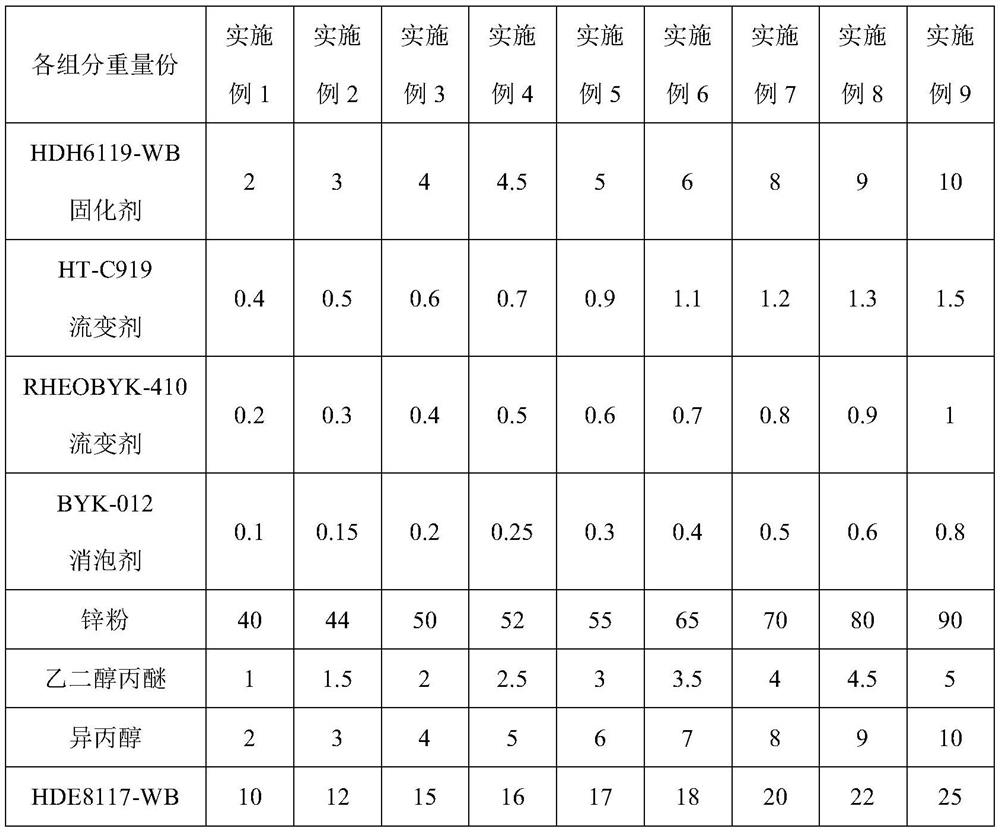

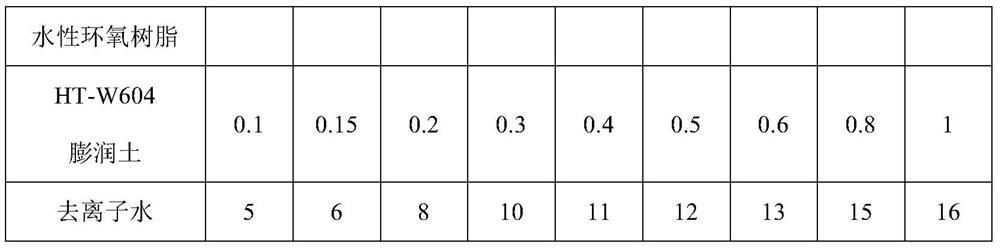

[0042] An epoxy zinc-rich primer, each component and its corresponding parts by weight are shown in Table 1.

preparation Embodiment 1

[0043] The preparation method of a kind of epoxy zinc-rich primer of preparation embodiment 1 may further comprise the steps:

[0044] Step 1, prepare the curing agent in component A (HDH6119-WB curing agent produced by our company): mix 0.8g polyamide resin 140, 0.2g surfactant, and 1g deionized water evenly to obtain HDH6119-WB curing agent agent, spare;

[0045] Step 2, prepare the water-based epoxy resin in component B (HDE8117-WB epoxy water-based dispersion produced by our company):

[0046]Mix 5.4g of epoxy resin DER331, 1g of surfactant, and 3.6g of deionized water evenly to obtain HDE8117-WB water-based epoxy resin for later use;

[0047] Step three, prepare component A:

[0048] Add HDH6119-WB curing agent 2g, 0.4g HT-C919 rheology agent, 0.2g RHEOBYK-410 rheology agent, 0.1g BYK-012 defoamer prepared in step 1 to 1g ethylene glycol propyl ether, 2g isopropyl In the mixed solvent of alcohol, disperse evenly, add 40g of 800 mesh zinc powder at the stirring speed of...

Embodiment 2~9

[0055] Embodiment 2~9: a kind of epoxy zinc-rich primer, the difference with embodiment 1 is: each component and its corresponding parts by weight are different from embodiment 1, its specific composition and corresponding parts by weight Number is as shown in table 1, and its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com