Photonic crystal template based gold or silver inverse opal microspheres and preparation method thereof

A technology of photonic crystal microspheres and inverse opals, which is applied in the direction of metal material coating process, liquid chemical plating, coating, etc., to achieve the effect of simple preparation process and various materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

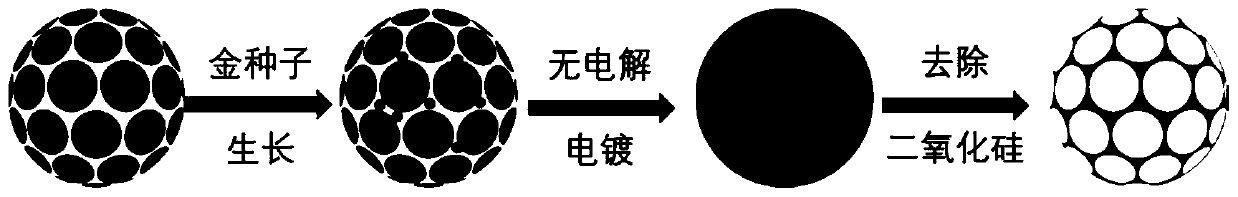

[0032] A preparation method based on photonic crystal template gold inverse opal microspheres (such as figure 1 shown), including the following steps:

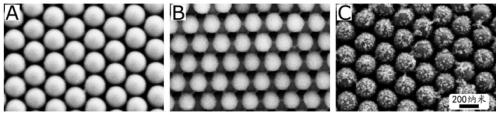

[0033] 1) Pre-treatment of hole expansion, hydroxylation and amination of photonic crystal microspheres self-assembled from silica colloidal crystals (such as figure 2 ), the diameter of the microsphere is 60 μm, and the diameter of the silica colloidal crystal is 200 nm;

[0034] ① Soak the photonic crystal microspheres in 2% HF solution for 3 minutes to etch away part of the silicon oxide and increase the gap between the particles;

[0035] ②Then immersed the expanded photonic crystal microspheres in piranha solution overnight to make the surface of silicon oxide with hydroxyl groups;

[0036] ③ After washing the excess piranha solution, soak the microspheres in a 3% aminopropyltrimethoxysilane solution by mass to make the surface of the silicon oxide with amino groups;

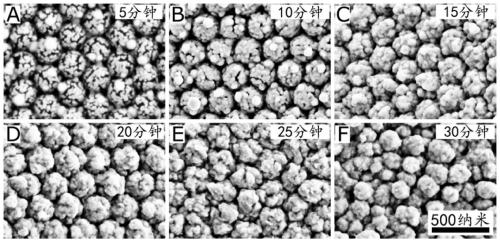

[0037] 2) Using the in-situ reduction method on t...

Embodiment 2

[0041] A preparation method based on photonic crystal template gold inverse opal microspheres, comprising the following steps:

[0042] 1) The photonic crystal microspheres self-assembled from silica colloidal crystals are subjected to hole expansion, hydroxylation and amination pretreatment, the diameter of the microspheres is 50 μm, and the diameter of the silica colloidal crystals is 300 nm;

[0043] ① Soak the photonic crystal microspheres in 1% HF solution for 5 minutes to etch away part of the silicon oxide and increase the gap between the particles;

[0044] ②Then immersed the expanded photonic crystal microspheres in piranha solution overnight to make the surface of silicon oxide with hydroxyl groups;

[0045] ③ After washing the excess piranha solution, soak the microspheres in 5% aminopropyltrimethoxysilane solution to make the surface of the silicon oxide with amino groups;

[0046] 2) Using the electrostatic adsorption method on the pretreated SiO 2 Gold seeds ar...

Embodiment 3

[0050] A preparation method based on photonic crystal template silver inverse opal microspheres, comprising the following steps:

[0051] 1) The photonic crystal microspheres self-assembled from silica colloidal crystals are subjected to hole expansion, hydroxylation, and amination pretreatment, the diameter of the microspheres is 60 μm, and the diameter of the silica colloidal crystals is 200 nm;

[0052] ① Soak the photonic crystal microspheres in 1.5% HF solution for 4 minutes to etch away part of the silicon oxide and increase the gap between the particles;

[0053] ②Then immersed the expanded photonic crystal microspheres in piranha solution overnight to make the surface of silicon oxide with hydroxyl groups;

[0054] ③ After washing the excess piranha solution, soak the microspheres in 4% APTES solution to bring amino groups on the surface of the silicon oxide;

[0055] 2) Using the in-situ reduction method on the pretreated SiO 2 Loading gold seeds in particle voids: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com