A multi-layer composite camouflage cloth with high thermal inertia

A multi-layer composite, high-heat technology, applied in the field of camouflage cloth, can solve the problems of large thermal inertia, achieve good quality, strong adhesion, and improve the effect of thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

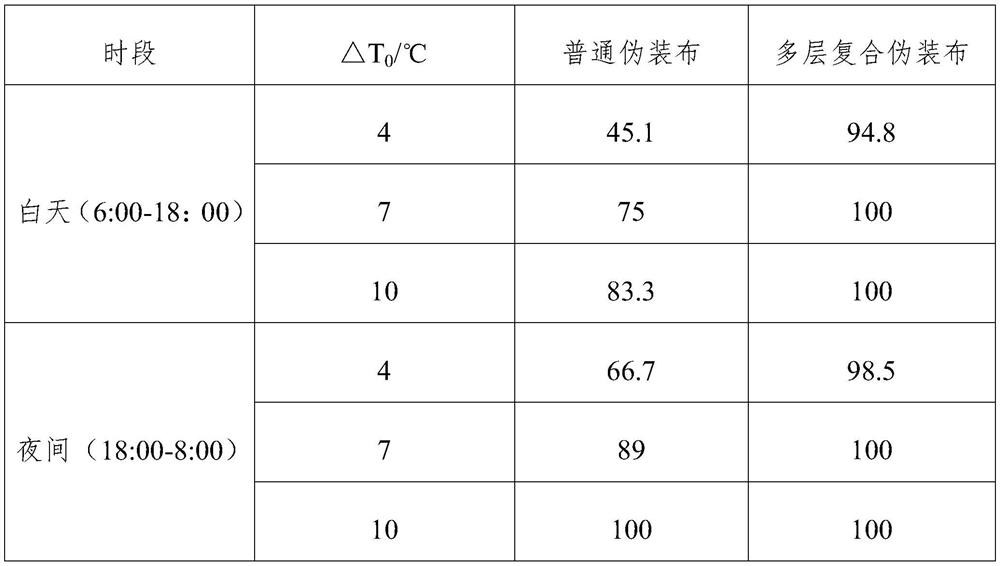

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A multi-layer composite camouflage cloth with high thermal inertia, including a base cloth, phase change material coatings are provided on both sides of the base cloth, camouflage coatings and thermal infrared high-reflection coatings are respectively provided on the outer sides of the two phase change material coatings .

[0024] The camouflage coating is composed of green camouflage paint. The green camouflage paint includes pigments, adhesives and solvents. The pigments include chromium oxide green, chromium oxide yellow, titanium white, macromolecular red and high-reflection black. The adhesive is polyurethane resin, and the solvent is It is dimethyl formamide, the components are calculated by weight, 15% of chrome oxide green, 20% of chrome oxide yellow, 10% of titanium white, 0.2% of macromolecular red, 1% of high reflection black, 30% of polyurethane resin, dimethylformamide Base formamide 8%.

[0025] The preparation method of the green camouflage paint is as f...

Embodiment 2

[0031] A multi-layer composite camouflage cloth with high thermal inertia, including a base cloth, phase change material coatings are provided on both sides of the base cloth, camouflage coatings and thermal infrared high-reflection coatings are respectively provided on the outer sides of the two phase change material coatings .

[0032] The camouflage coating is composed of green camouflage paint. The green camouflage paint includes pigments, adhesives and solvents. The pigments include chromium oxide green, chromium oxide yellow, titanium white, macromolecular red and high-reflection black. The adhesive is polyurethane resin, and the solvent is It is dimethyl formamide, the components are calculated by weight, 20% of chrome oxide green, 15% of chrome oxide yellow, 12% of titanium white, 0.4% of macromolecular red, 2% of high reflection black, 40% of polyurethane resin, dimethylformamide Base formamide 10%.

[0033] The preparation method of the green camouflage paint is as ...

Embodiment 3

[0039] A multi-layer composite camouflage cloth with high thermal inertia, including a base cloth, phase change material coatings are provided on both sides of the base cloth, camouflage coatings and thermal infrared high-reflection coatings are respectively provided on the outer sides of the two phase change material coatings .

[0040] The camouflage coating is composed of green camouflage paint. The green camouflage paint includes pigments, adhesives and solvents. The pigments include chromium oxide green, chromium oxide yellow, titanium white, macromolecular red and high-reflection black. The adhesive is polyurethane resin, and the solvent is It is dimethyl formamide, the components are calculated by weight, 24% of chrome oxide green, 20% of chrome oxide yellow, 15% of titanium white, 0.5% of macromolecular red, 5% of high reflection black, 50% of polyurethane resin, dimethylformamide Base formamide 15%.

[0041] The preparation method of the green camouflage paint is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com