Preparation method of lyophilization type determination PT reagent

A technology of freeze-dried protective agent and reagent, which is applied in the field of preparation of freeze-dried PT reagents, can solve the problems of insufficient protection effect and obvious prolongation of validity period, and achieve easy production, overcome the problem of loss of thromboplastin, and high The effect of clinical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

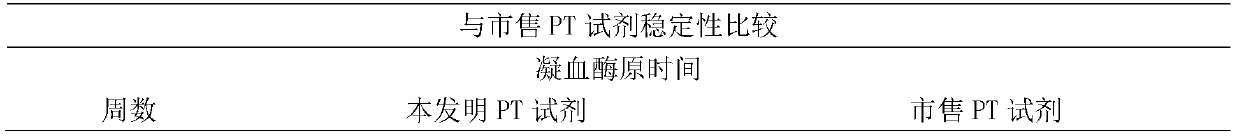

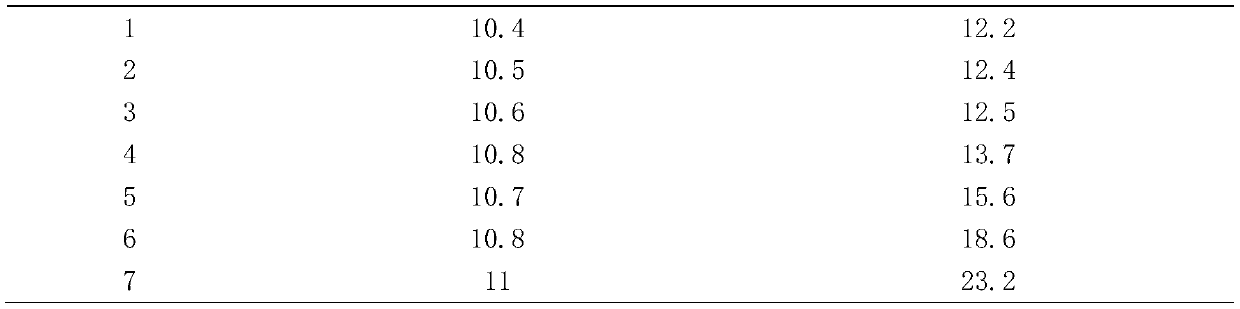

Examples

Embodiment 1

[0020] Including the following steps:

[0021] Q1. Add 3% sodium glutamate, 10% inulin oligosaccharides, and 1% bovine serum albumin into the prepared HEPES buffer. The pH of the HEPES buffer is between 6.4-7.4 In between, stir for 15 minutes to obtain a uniform protective agent solution;

[0022] Q2, dissolving an appropriate amount of synthetic phospholipids in the HEPSE buffer solution containing 1% triton, after stirring for 120 minutes, to obtain a uniformly dispersed phospholipid solution, the mass fraction of the surfactant is 1.0%;

[0023] Q3. Express sheep tissue factor in Escherichia coli by genetic engineering, prepare sheep tissue factor with a purity of more than 90%, and dissolve the sheep tissue factor in an appropriate amount of PBS buffer to form a 55ug / ml recombinant sheep tissue factor solution;

[0024] Q4. Add recombinant sheep tissue factor solution and phospholipid solution, the mass ratio of phospholipid to recombinant sheep tissue factor is 2.8×10 3...

Embodiment 2

[0027] Including the following steps:

[0028] Q1. Add 5% sodium glutamate, 5% inulin oligosaccharides, and 2% bovine serum albumin into the prepared HEPES buffer. The pH of the HEPES buffer is between 6.4-7.4 In between, stir for 15 minutes to obtain a uniform protective agent solution;

[0029] Q2, dissolving an appropriate amount of synthetic phospholipids in the HEPSE buffer solution containing 1% triton, after stirring for 120 minutes, to obtain a uniformly dispersed phospholipid solution, the mass fraction of the surfactant is 1.5%;

[0030] Q3. Express sheep tissue factor in Escherichia coli by genetic engineering, prepare sheep tissue factor with a purity of more than 90%, and dissolve the sheep tissue factor in an appropriate amount of PBS buffer to form a 55ug / ml recombinant sheep tissue factor solution;

[0031] Q4. Add recombinant sheep tissue factor solution and phospholipid solution, the mass ratio of phospholipid to recombinant sheep tissue factor is 2.8×10 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com