Secondary via hole reflow soldering method

A secondary via and reflow soldering technology, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc., to achieve the effects of improving PCB solderability, shortening production cycle, and reducing materials and personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

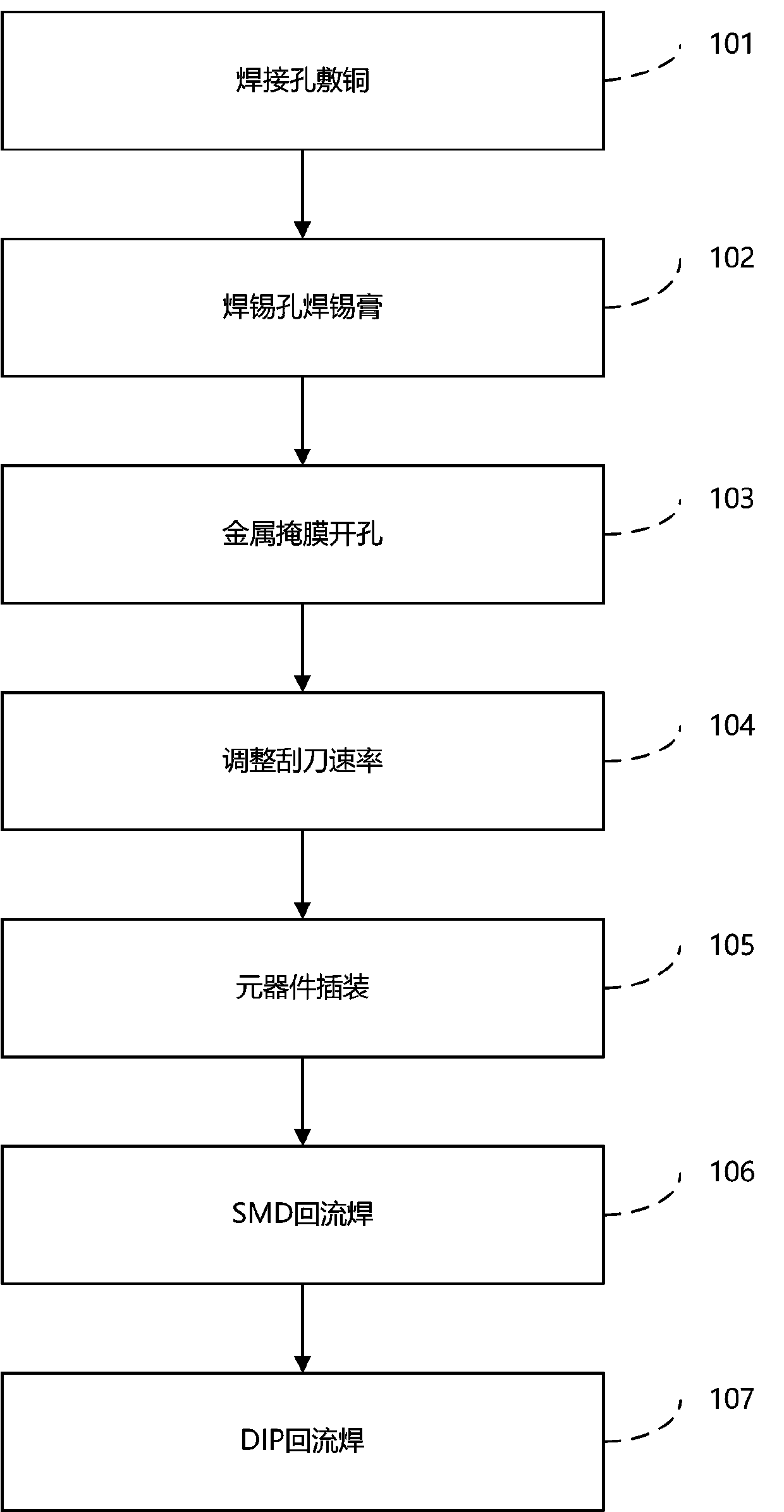

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0025] At present, due to the thickness of some PCBs in the via reflow soldering process is 1.6T, and the pins of some components are hollow, after the reflow soldering process, the non-component surface of the PBA shows that the amount of tin is insufficient. In fact, the inside has been soldered. Some technologies use partially thickened aluminum alloy steel mesh (Mental Mask) to solve it.

[0026] For the via-hole reflow soldering process, the soldering state of the solder joint depends on the volume of the alloy formed after the reflow of the solder in the solder hole. Since the volume of the solder paste is reduced to about 50% of the tin content, for thicker PCB through holes Due to the reduction of the attachment carrier of the solder paste, it is more likely to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com