A kind of iron tailings composite self-insulation block and preparation method thereof

A technology of self-insulating blocks and iron tailings, applied in ceramic products, other household utensils, sustainable waste treatment, etc., can solve problems such as safety hazards and non-environmental protection, so as to relieve environmental pressure, reduce consumption, increase resistance The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

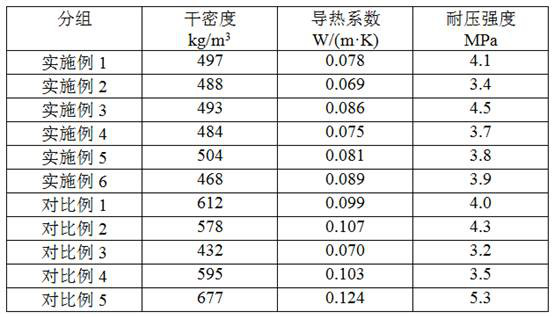

Examples

Embodiment 1

[0039] The invention relates to a composite self-insulation block of iron tailings, which is composed of an insulation inner core and a load-bearing frame covered outside the insulation inner core. The preparation method of the iron tailings composite self-insulation block first prepares the insulation inner core, and then carries out the preparation process of coating the load-bearing frame on the outside of the insulation inner core, and finally prepares the iron tailings composite self-insulation block . The weight ratio of the thermal insulation inner core to the load-bearing frame is 3:7.

[0040] 1. The preparation of the thermal insulation inner core is calculated in parts by weight, and the steps are as follows:

[0041] 1) Grinding and pulverizing the iron tailings and passing through a 120-mesh sieve to obtain iron tailings powder with a mesh size greater than 120 mesh;

[0042] 2) Take 30 parts of iron tailings powder obtained in step 1), 90 parts of cement, 30 pa...

Embodiment 2

[0053] The invention relates to a composite self-insulation block of iron tailings, which is composed of an insulation inner core and a load-bearing frame covered outside the insulation inner core. The preparation method of the iron tailings composite self-insulation block first prepares the insulation inner core, and then carries out the preparation process of coating the load-bearing frame on the outside of the insulation inner core, and finally prepares the iron tailings composite self-insulation block . The weight ratio of the thermal insulation inner core to the load-bearing frame is 4:6.

[0054] The preparation process of the thermal insulation inner core was repeated in Example 1, but the difference from Example 1 was that in the preparation process of the thermal insulation inner core, the amount of iron tailings powder added in step 2) was replaced by 50 parts, and the The amount of cement added in step 2) was replaced by 120 parts, and the rest of the conditions we...

Embodiment 3

[0057] The invention relates to a composite self-insulation block of iron tailings, which is composed of an insulation inner core and a load-bearing frame covered outside the insulation inner core. The preparation method of the iron tailings composite self-insulation block first prepares the insulation inner core, and then carries out the preparation process of coating the load-bearing frame on the outside of the insulation inner core, and finally prepares the iron tailings composite self-insulation block . The weight ratio of the thermal insulation inner core to the load-bearing frame is 2:8.

[0058] The preparation process of the thermal insulation inner core is repeated in Example 1, but the difference from Example 1 is that in the preparation process of the thermal insulation inner core, the amount of iron tailings powder added in step 2) is replaced by 20 parts, and the The amount of cement added in step 2) was replaced by 50 parts, and the rest of the conditions were t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com