Preparation method of epoxy phenyl silicone rubber

A technology of phenyl silicone rubber and epoxidized benzene, which is applied in the field of silicone rubber, can solve problems such as corrosion of metal reactors and troublesome construction of industrial production lines, and achieve the effects of improving efficiency, shortening reaction time, and mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

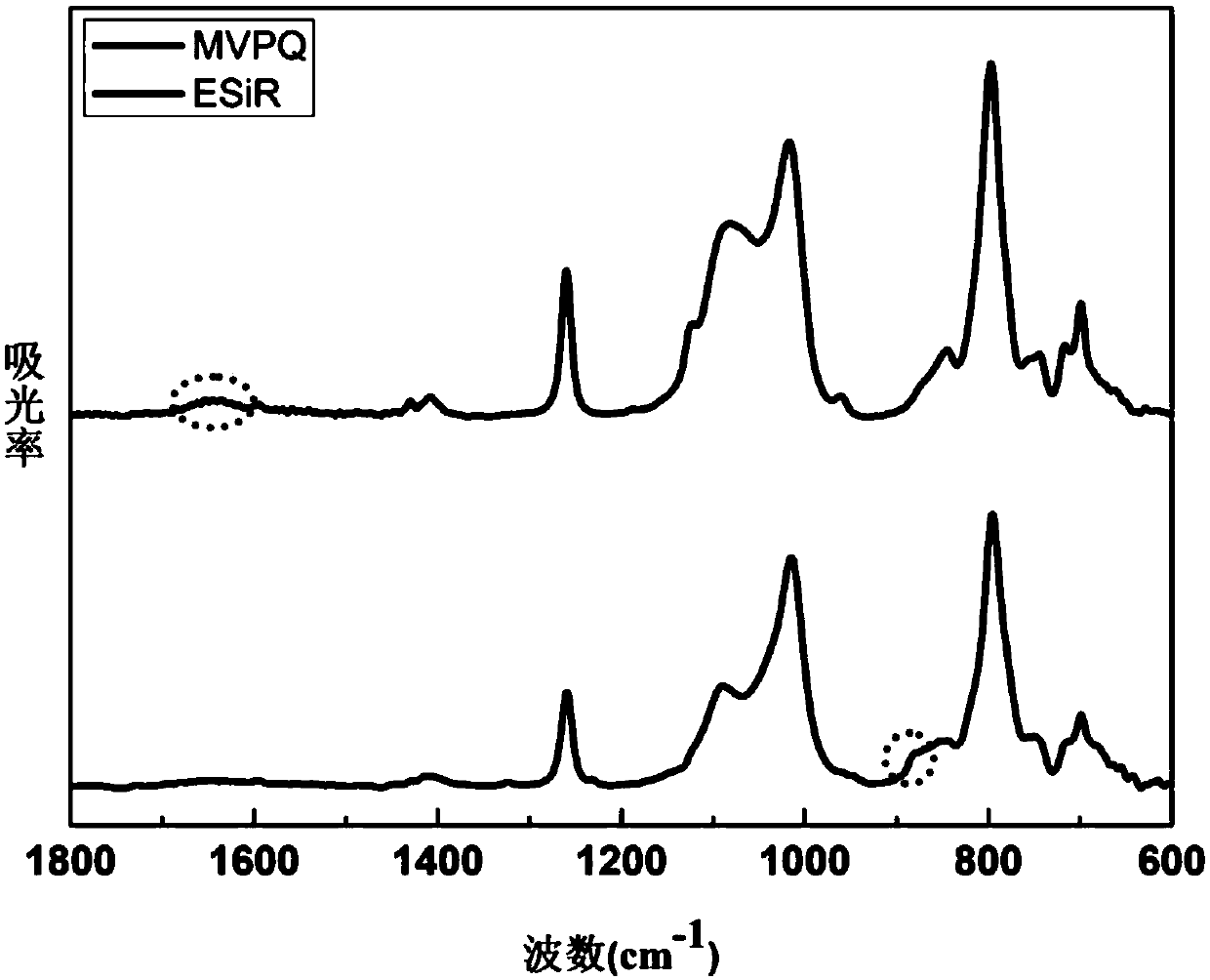

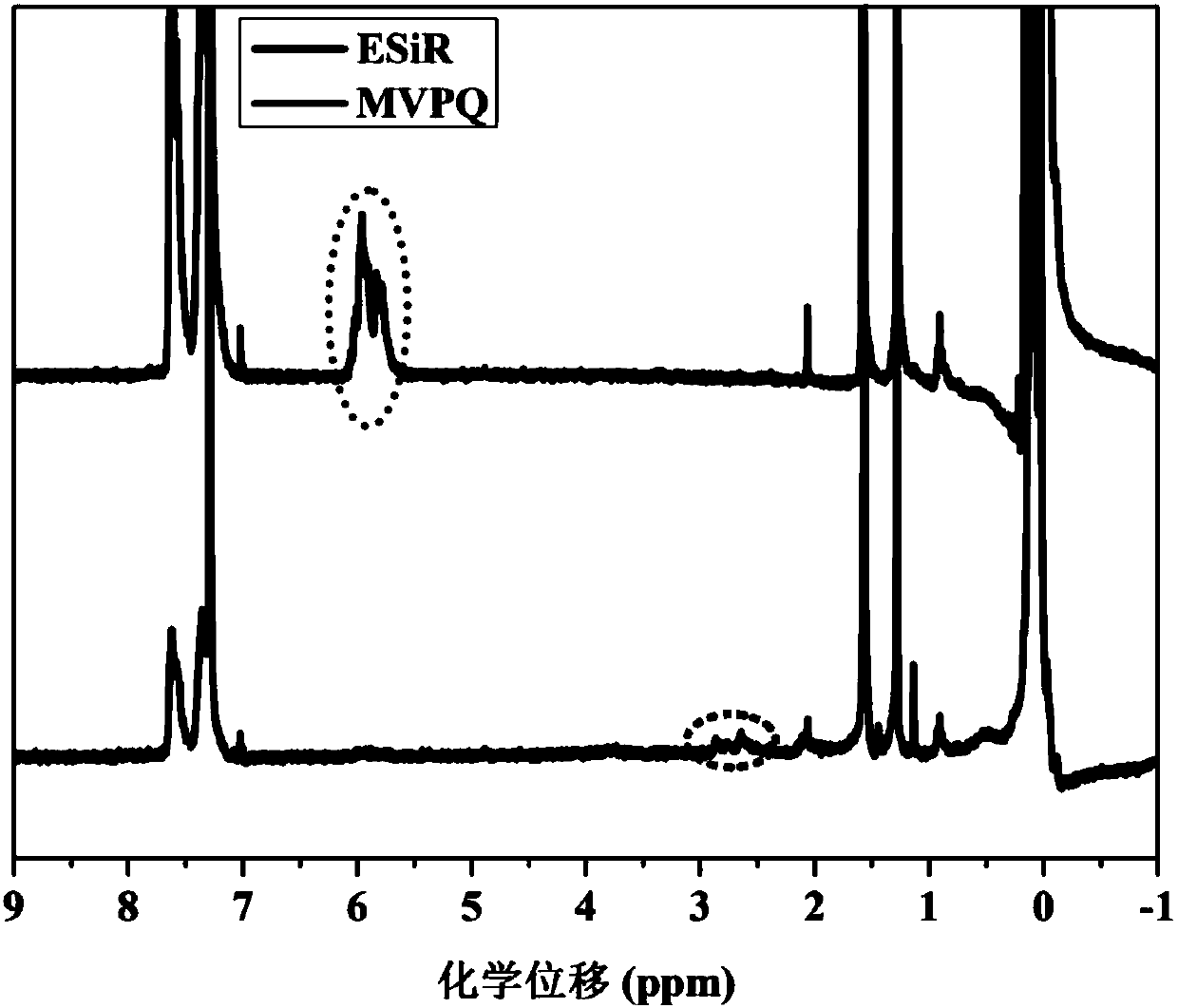

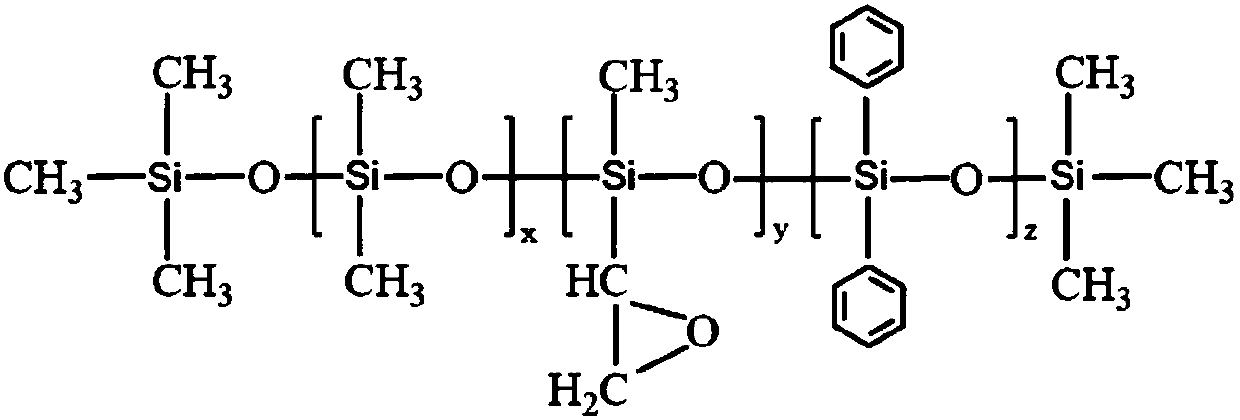

[0040] Add 200mL of chlorobenzene and vinyl content to 14.13% in the 250mL round-bottomed flask equipped with magnetic stirring, and 10g of phenyl silicone rubber (self-made) with phenyl content of 22.30%, control the temperature of the water bath at 55°C and 250 rpm stirring rate. After the phenyl silicone rubber is completely dissolved, add 3.68g m-chloroperoxybenzoic acid (the ratio of peroxyacid to double bond is 1:1.3) to start the reaction. After 72 hours, it is precipitated with methanol, washed 2-3 times, and placed in a vacuum Oven dry for 12h, take out.

[0041] Wherein the preparation method of phenyl silicone rubber:

[0042] (1) Add 48.20 g of octamethylcyclotetrasiloxane and 12.92 g of tetramethyltetravinylcyclotetrasiloxane into the reaction flask, vacuumize and remove water at 45-50°C for 1 hour, and then under nitrogen protection Add 0.75g of alkali gel catalyst and 0.03g of decamethyltetrasiloxane as an end-capping agent, and finally add 39.66g of octapheny...

Embodiment 2

[0049] Add 200mL chlorobenzene and vinyl content to 250mL round-bottomed flask equipped with magnetic sub-stirring and be 14.13%, phenyl silicone rubber (self-made) 6g that phenyl content is 22.30%, control water bath temperature to be 55 ℃ and 250 to rotate stirring rate. After the phenyl silicone rubber is completely dissolved, add 2.21g of m-chloroperoxybenzoic acid (the ratio of peroxyacid to double bond is 1:1.3) to start the reaction. After 72 hours, it is precipitated with methanol, washed 2-3 times, and placed in a vacuum Oven dry for 12h, take out. Characterized by NMR, the epoxidation conversion rate was 94.2%.

[0050] Wherein the preparation method of phenyl silicone rubber is the same as that of Example 1.

Embodiment 3

[0052]Add 200mL of chlorobenzene and vinyl content to 14.13% in the 250mL round-bottomed flask equipped with magnetic stirring, and 10g of phenyl silicone rubber (self-made) with phenyl content of 22.30%, control the temperature of the water bath at 55°C and 250 rpm stirring rate. After the phenyl silicone rubber is completely dissolved, add 3.68g m-chloroperoxybenzoic acid (the ratio of peroxyacid to double bond is 1:1.3) to start the reaction. After 96h, it is precipitated with methanol, washed 2-3 times, and placed in a vacuum Oven dry for 12h, take out. Characterized by NMR, the epoxidation conversion rate was 96.3%.

[0053] Wherein the preparation method of phenyl silicone rubber is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com