Process method for performing advanced treatment on petrochemical wastewater through catalytic ozonation

A technology of ozone catalytic oxidation and advanced treatment, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of increasing investment costs, difficulty in operation and management, incomplete ozone oxidation, and restrictions on large-scale application, so as to improve the utilization rate of ozone and catalyze Oxidation efficiency, improvement of ozone catalytic oxidation efficiency and ozone utilization rate, and the effect of preventing poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

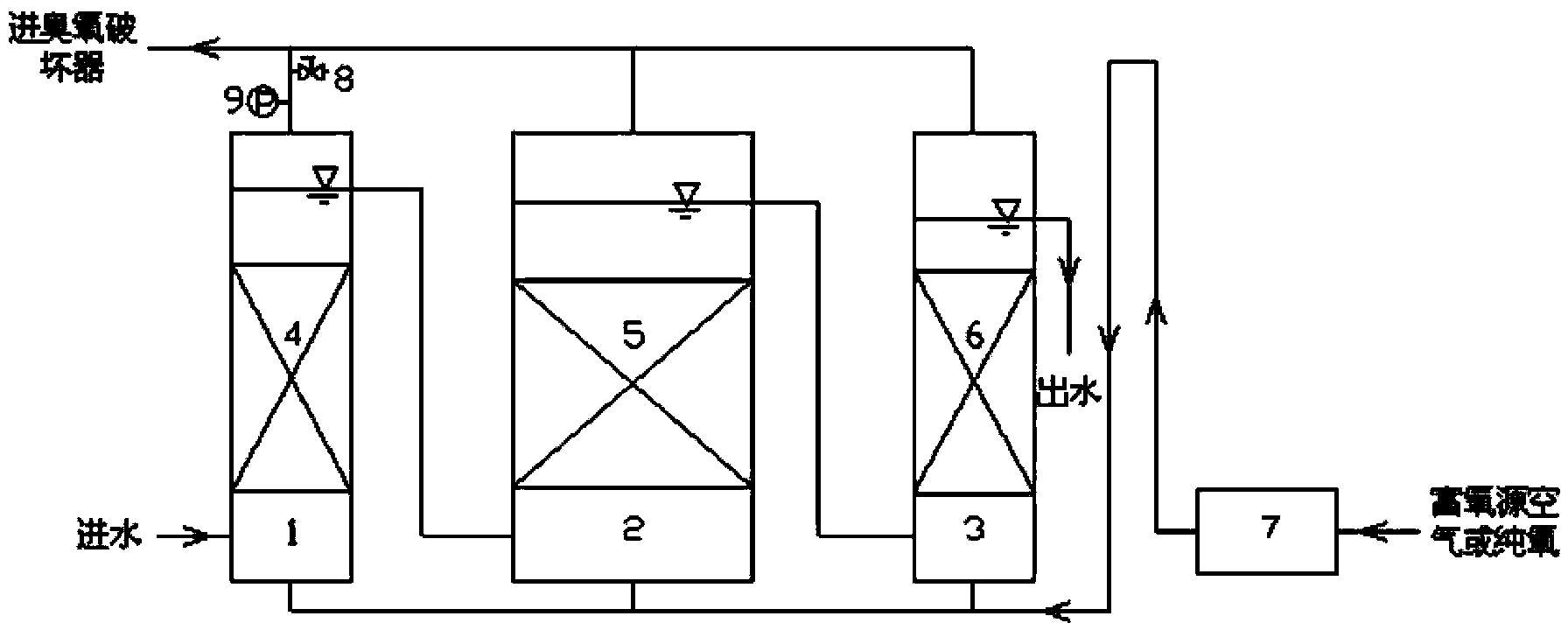

[0020] A refining and chemical company in Heilongjiang has a daily wastewater treatment volume of 2400m3 / d, which is currently treated by a secondary biochemical process. In order to realize the comprehensive reuse of sewage, it is planned to upgrade the existing process and add an advanced treatment unit on the basis of the original secondary biochemical treatment process. Adopt the ozone catalytic oxidation process method of the present invention (attachment figure 1 (shown) advanced treatment of the secondary biochemical effluent, and carried out a field pilot test with a scale of 15m3 / d. The hydraulic retention time of the factory's secondary biochemical effluent in the pre-oxidation tower 1, catalytic oxidation tower Ⅰ2 and catalytic oxidation tower Ⅱ3 are 0.5h, 1h and 0.5h respectively, and the dosage of ozone is 30~45mg / L, 30~ 45mg / L and 10~15mg / L. The pre-oxidation tower 2 operates under pressure, and the pressure is controlled at 0.02~0.05Mpa. Ozone is produced by ...

Embodiment 2

[0023] A petrochemical company in Guangdong treats 1200m3 of waste water per day. At present, it adopts secondary biochemical process for treatment, and there is a problem that the waste water is difficult to meet the discharge standard. Adopt the ozone catalytic oxidation process method of the present invention ( figure 1 Shown) was carried out on-site small test research. The hydraulic retention time of the plant's secondary biochemical effluent in the pre-oxidation tower 1, catalytic oxidation tower Ⅰ2 and catalytic oxidation tower Ⅱ3 are 0.5h, 1.5h and 0.5h respectively, and the dosage of ozone is 60~80mg / L, 40 ~60mg / L and 30~40mg / L. The pre-oxidation tower 2 operates under pressure, and the pressure is controlled at 0.02~0.05Mpa. Ozone is produced by an oxygen-enriched source ozone generator 7, and the ozone concentration is 100-150 mg / L.

[0024] The influent COD of the advanced treatment device is 128-325 mg / L, with an average of 234 mg / L. After being treated by the ...

Embodiment 3

[0026] A petrochemical company in Tianjin treats 1,800m3 of waste water per day. Currently, it adopts a secondary biochemical process for treatment. Occasionally, the waste water does not meet the standard. It plans to increase the ozone catalytic oxidation advanced treatment process ( figure 1 shown), and conducted a field test study on it. The hydraulic retention time of the factory's secondary biochemical effluent in the pre-oxidation tower 1, catalytic oxidation tower Ⅰ2 and catalytic oxidation tower Ⅱ3 are 10min, 15min and 10min respectively, and the dosage of ozone is 10~15mg / L and 10~15mg / L respectively. L and 5~10 mg / L. The pre-oxidation tower 2 operates under pressure, and the pressure is controlled at 0.02~0.05Mpa. Ozone is produced by an oxygen-enriched source ozone generator 7 with an ozone concentration of 50-80 mg / L.

[0027] The influent COD of the advanced treatment device is 78-135 mg / L, with an average of 107 mg / L. After being treated by the process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com