Method for preparing polyimide film by microwave radiation at low temperature

A technology of polyimide film and microwave radiation, which is applied in the field of preparing polyimide film at low temperature through microwave radiation, can solve the problem of thermal performance degradation of synthetic polyimide, performance degradation of polyimide film, and unfavorable large-scale production and other issues, to achieve the effect of reducing the requirements for instruments, improving production efficiency, and facilitating industrial production and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

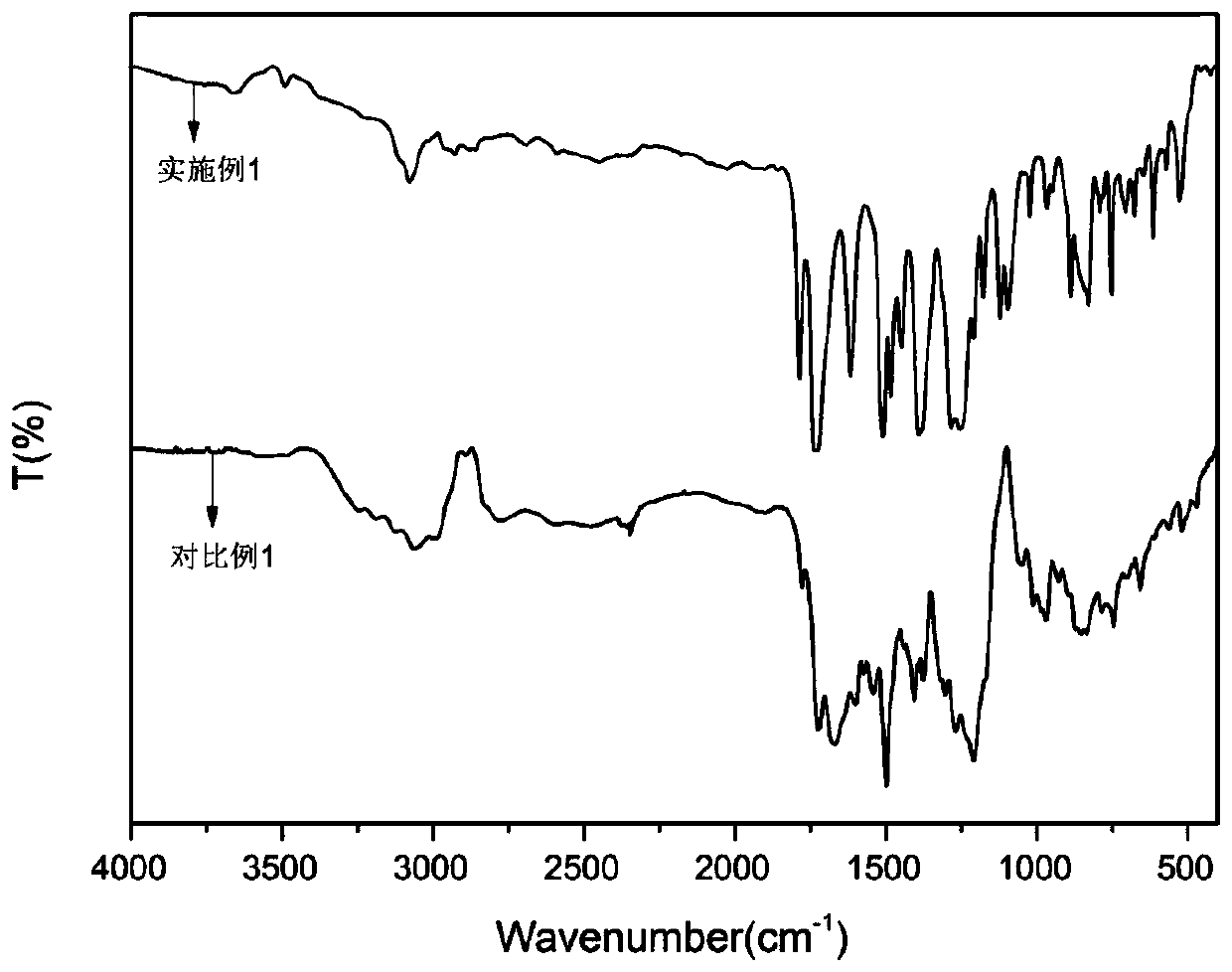

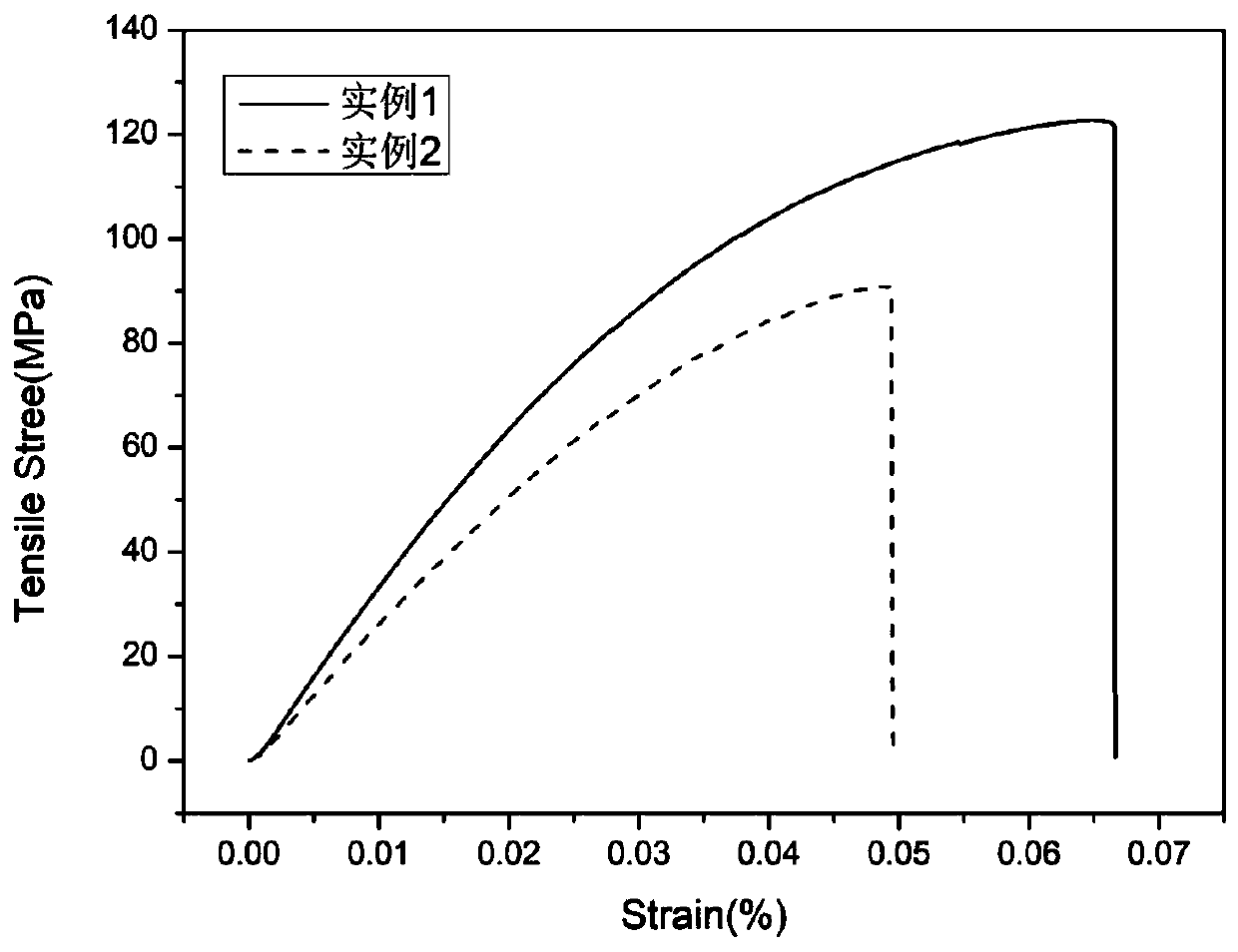

Embodiment 1

[0035] Under normal temperature and pressure conditions, in a 250ml three-necked flask, add 10 grams of ODPA and 65.8 grams of NMP and add magnets, use a magnetic stirrer to stir evenly, then add 6.45 grams of ODA, ODPA (dibasic acid anhydride) and ODA (dibasic amine ) in a molar ratio of 1:1, and the feeding of the diamine was carried out three times with an interval of 20 minutes between each feeding. The reddish-brown viscous polyimide precursor solution is product A. Put the polyimide precursor solution into the microwave equipment, and irradiate for 20 minutes under the conditions of 1000W and 70°C to obtain product B. Pour product B on a quartz glass plate, and use a wire bar coater to spread the film to obtain product C, then put it in a vacuum oven, heat for 4 hours at 80°C and a vacuum of 30kPa to remove the solvent, and obtain product D . Put product D into microwave equipment, and cure it at 2000W, 70°C for 18 hours, and finally prepare the film material. The pre...

Embodiment 2

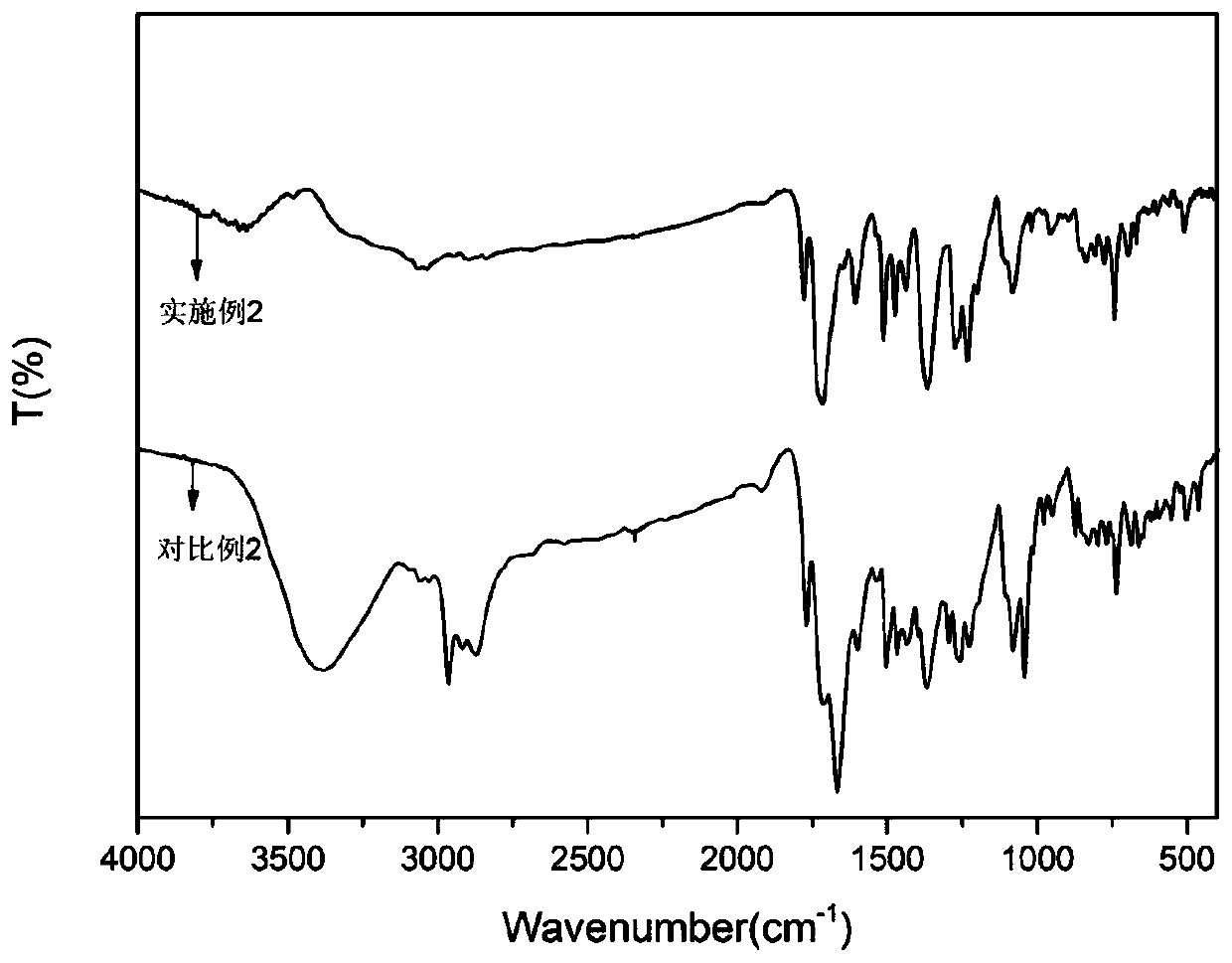

[0041] Under normal pressure, heat the heat conduction oil in the oil bath to 80°C in advance, add 10 grams of ODPA and 78 grams of NMP to a 250ml three-necked flask and add magnets, and then load the three-necked flask to the specified temperature in advance In the oil bath pot, use a magnetic stirrer to stir, the stirring speed is 200rpm, nitrogen protection, the nitrogen outlet passes through the top of the spherical condenser to prevent the solvent from being blown out by the nitrogen flow. After fully dissolving, add 9.4 grams of MDI, the molar ratio of MDI (isocyanate) and ODPA (dibasic acid anhydride) is 1:1, the addition of isocyanate is carried out three times, and the length of addition is 1 hour. After the addition is completed, stir magnetically at room temperature for 6 Hours, make it fully react, obtain solid content and be that the polyimide precursor solution of 20% clear transparent dark reddish-brown viscous shape is B product. Put the polyimide precursor sol...

Embodiment 3

[0047] A method for preparing polyimide film at low temperature by microwave radiation, comprising the following steps:

[0048] The first step is to prepare a polyimide precursor solution to obtain product A;

[0049] In the second step, product A is subjected to microwave radiation treatment to obtain product B;

[0050] In the third step, product B is subjected to coating treatment to obtain product C;

[0051] In the fourth step, product C is heated to obtain product D;

[0052] The fifth step is to carry out imidization treatment on product D by low-temperature microwave radiation to obtain a finished product;

[0053] In the fifth step, the temperature is 60-100°C.

[0054] The preparation of polyimide precursor solution comprises the following specific steps in the first step:

[0055] A1. Add an aprotic polar solvent into a three-necked flask, then add dibasic acid anhydride, add magnetons, and stir evenly with a magnetic stirrer to obtain a solution;

[0056] A2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com