Special material for flame-retardant plastic sheets for steel coil packaging, and preparation method thereof

A technology for plastic sheets and packaging, applied in the field of packaging materials, can solve the problems of flammability, low tensile strength, and poor impact resistance, and achieve the effects of enhanced fluidity, good mechanical properties, and improved anti-aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

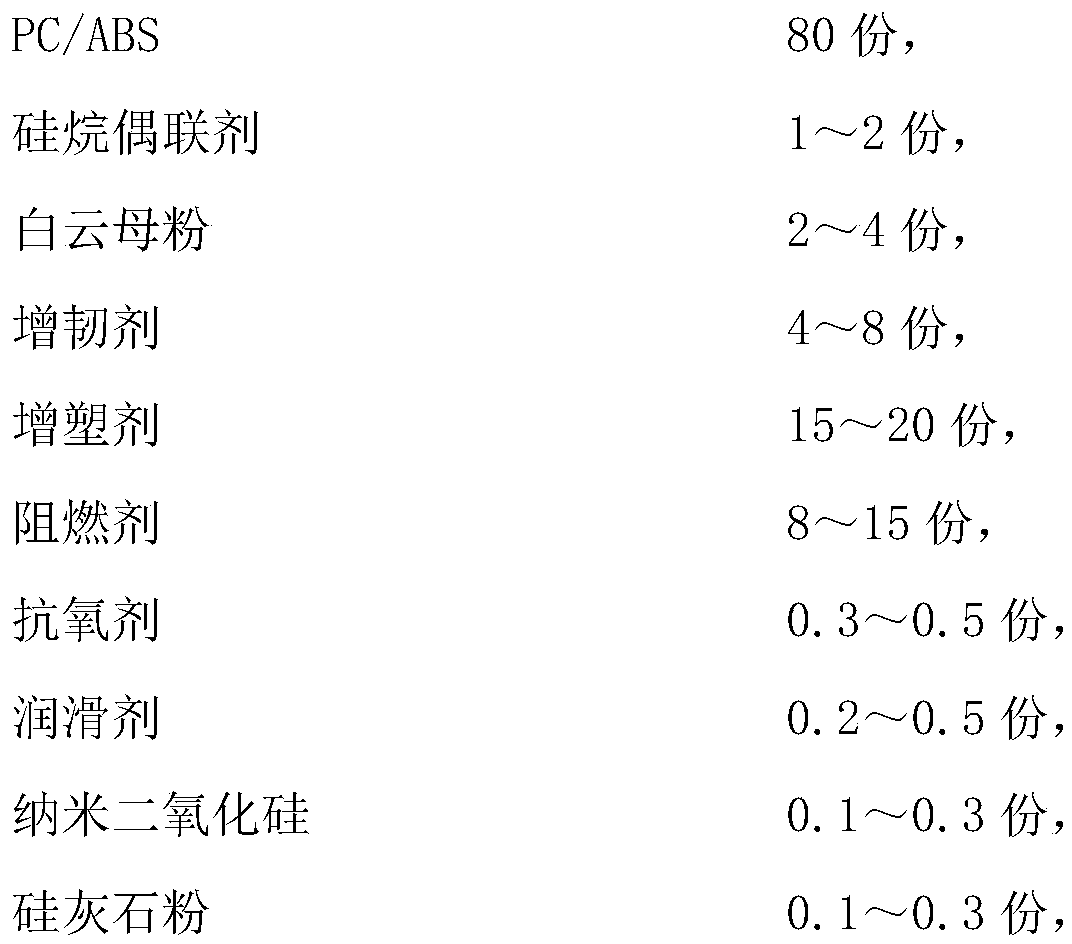

[0016] A special flame-retardant plastic sheet material for steel coil packaging, in parts by weight, its raw material composition includes:

[0017]

[0018]

[0019] The flame retardant is composed of the following raw materials in parts by weight: 20 parts of meta-aramid fiber, 10 parts of zinc borate, and 5 parts of xanthan gum;

[0020] Described toughening agent is ethylene-methyl acrylate copolymer;

[0021] Described plasticizer is made up of glyceryl monostearate, chlorinated paraffin that weight ratio is 2:1;

[0022] The antioxidant is composed of BHT and powder phosphite in a weight ratio of 1.5:1;

[0023] The lubricant is composed of molybdenum disulfide and talcum powder in a weight ratio of 1:1.

[0024] The method for preparing the flame-retardant plastic steel sheet special material for steel coil packaging in this embodiment comprises the following process steps:

[0025] (1) Mix PC / ABS, silane coupling agent, muscovite powder, toughening agent, pla...

Embodiment 2

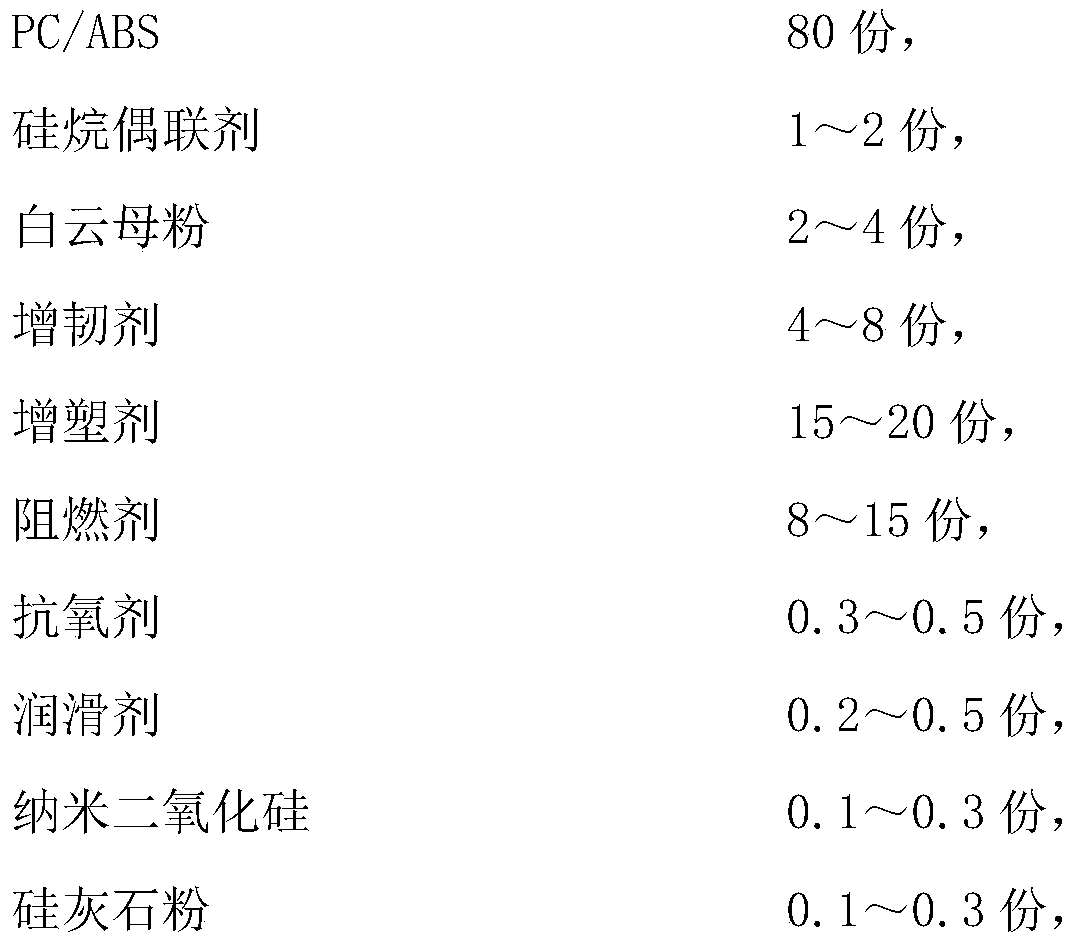

[0028] A special flame-retardant plastic sheet material for steel coil packaging, in parts by weight, its raw material composition includes:

[0029]

[0030]

[0031] The flame retardant is composed of the following raw materials in parts by weight: 30 parts of meta-aramid fiber, 20 parts of zinc borate, and 10 parts of xanthan gum;

[0032] Described toughening agent is styrene-maleic anhydride copolymer;

[0033] Described plasticizer is made up of glyceryl monostearate, chlorinated paraffin that weight ratio is 3:1;

[0034] The antioxidant is composed of BHT and powder phosphite in a weight ratio of 2:1;

[0035] The lubricant is composed of molybdenum disulfide and talcum powder in a weight ratio of 1:1.

[0036] The method for preparing the flame-retardant plastic steel sheet special material for steel coil packaging in this embodiment comprises the following process steps:

[0037] (1) Mix PC / ABS, silane coupling agent, muscovite powder, toughening agent, plas...

Embodiment 3

[0040] A special flame-retardant plastic sheet material for steel coil packaging, in parts by weight, its raw material composition includes:

[0041]

[0042] The flame retardant is composed of the following raw materials in parts by weight: 25 parts of meta-aramid fiber, 15 parts of zinc borate, and 8 parts of xanthan gum;

[0043] Described toughening agent is styrene-maleic anhydride copolymer;

[0044] Described plasticizer is made up of glyceryl monostearate, chlorinated paraffin that weight ratio is 2.5:1;

[0045] The antioxidant is composed of BHT and powder phosphite in a weight ratio of 1.5:1;

[0046] The lubricant is composed of molybdenum disulfide and talcum powder in a weight ratio of 1:1.

[0047] The method for preparing the flame-retardant plastic steel sheet special material for steel coil packaging in this embodiment comprises the following process steps:

[0048] (1) Mix PC / ABS, silane coupling agent, muscovite powder, toughening agent, plasticizer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com