Cooling flame low nitrogen combustion device and combustion method thereof

A low-nitrogen combustion and flame technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of fast propagation speed of fully premixed flame, inability to prevent tempering, and a large amount of nitrogen oxides, so as to avoid the concentration of high temperature areas. , Solve the effect of easy tempering and reducing the formation of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

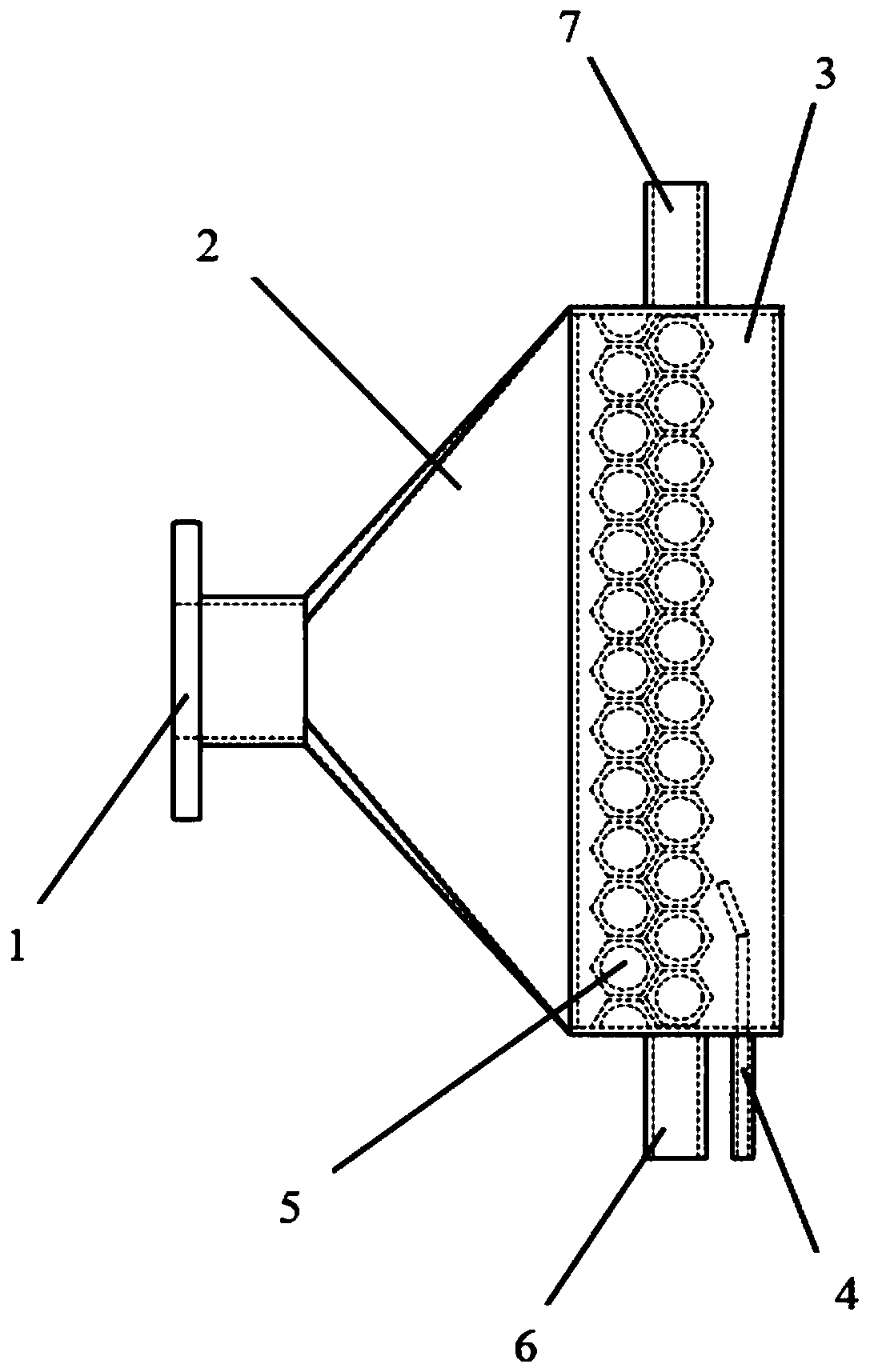

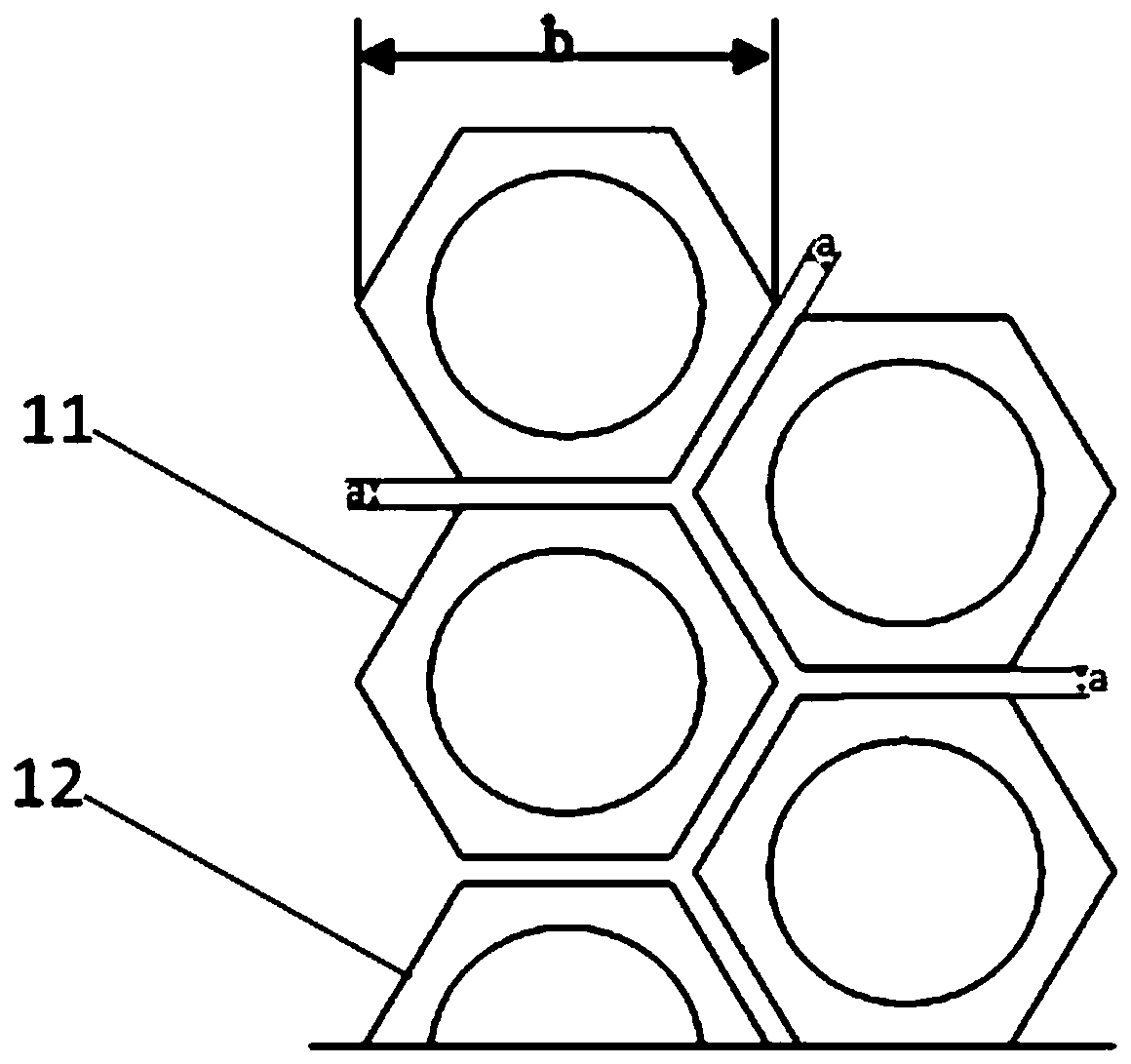

[0051] This embodiment provides a cooling flame low nitrogen combustion device, such as figure 1 As shown, it includes a premixed gas inlet 1, a distributing chamber 2, a combustion chamber 3, a first cooling liquid inlet 6 and a first cooling liquid outlet 7, and the combustion chamber 3 is sequentially provided with the first cooling liquid along the flow direction of the premixed gas A heat exchange tube assembly 5 and an igniter 4 . In this embodiment, the gas distributing chamber 2 is a trumpet-shaped structure, its narrow end is connected to the premixed gas inlet 1, and its wide end is connected to the combustion chamber 3; the first heat exchange tube assembly 5 It consists of two sets of vertical first heat exchange tube rows arranged in parallel. The first heat exchange tube row on the left side is close to the gas distribution chamber 2. It is formed by 11 outer hexagonal tubes arranged in parallel on the same plane. The right side The first heat exchange tube row ...

Embodiment 2

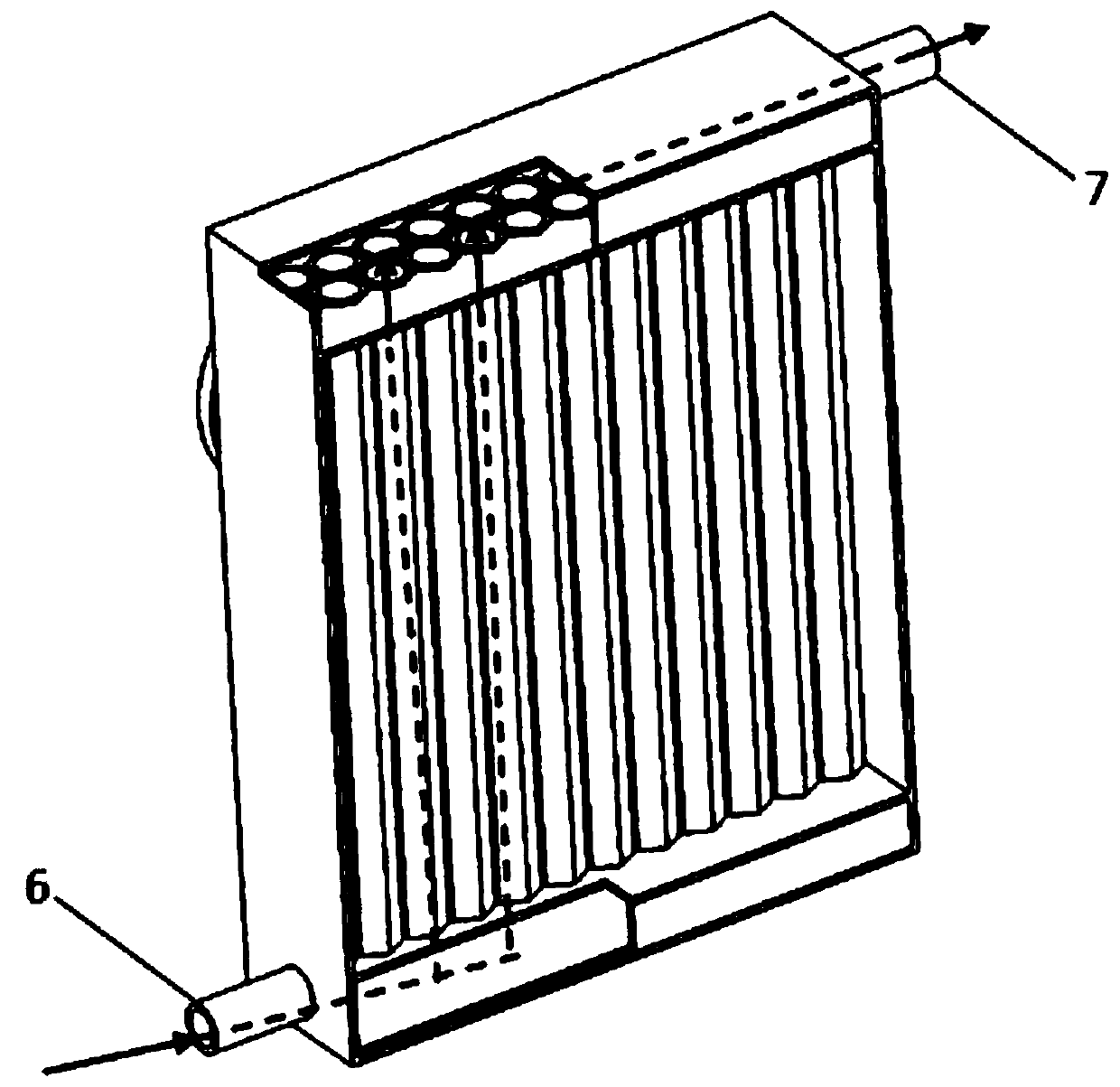

[0060] As another embodiment of the present invention, it is similar to Embodiment 1, except that: Figure 4 As shown, the combustion chamber 3 of the second embodiment also includes a second heat exchange tube assembly 8, and the second heat exchange tube assembly 8 is arranged behind the igniter 4 along the flow direction of the premixed gas. The distance between the heat exchange tube assembly 5 and the second heat exchange tube assembly 8 is 42mm.

[0061] In this embodiment, the second heat exchange tube assembly 8 is formed by three groups of second heat exchange tube rows arranged in parallel and at intervals, and the three groups of second heat exchange tube rows are respectively composed of 11, 10 and 11 The second heat exchange tubes are formed in parallel and spaced arrays on the same plane, and three adjacent heat exchange tubes are arranged in a triangular shape on a transverse cross section.

[0062] The combustion method of the cooling flame low-nitrogen combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com