Semiconductor process equipment and method for manufacturing semiconductor device

A process equipment and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as affecting yield, failing to meet device design specifications, and poor thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

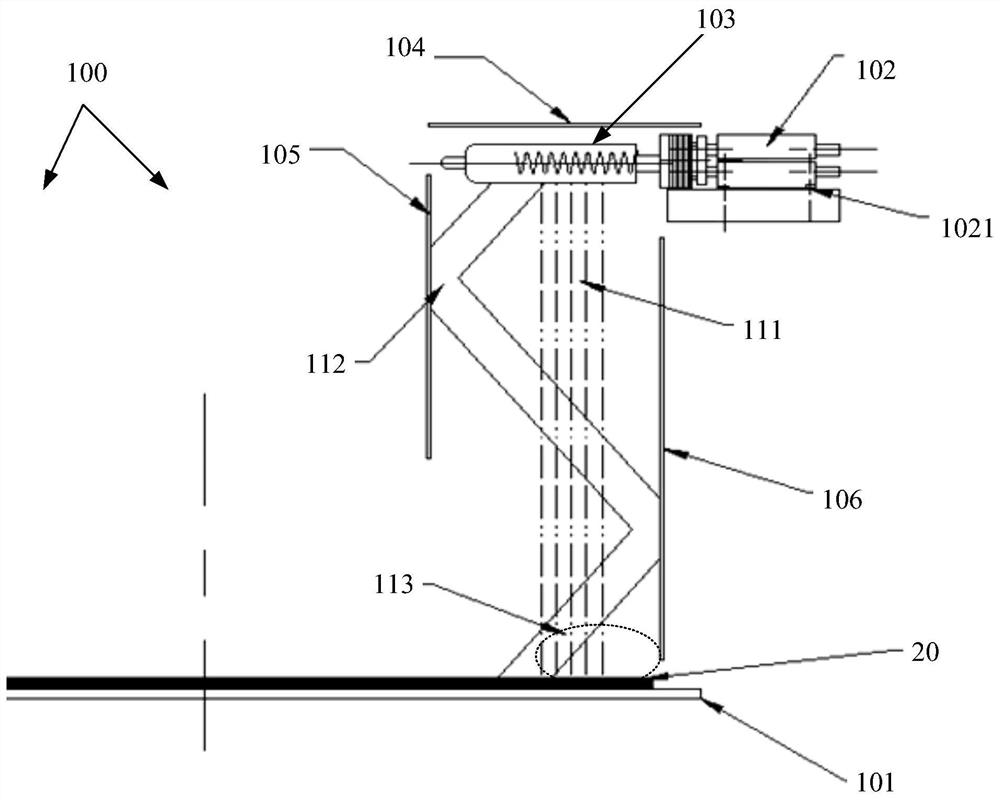

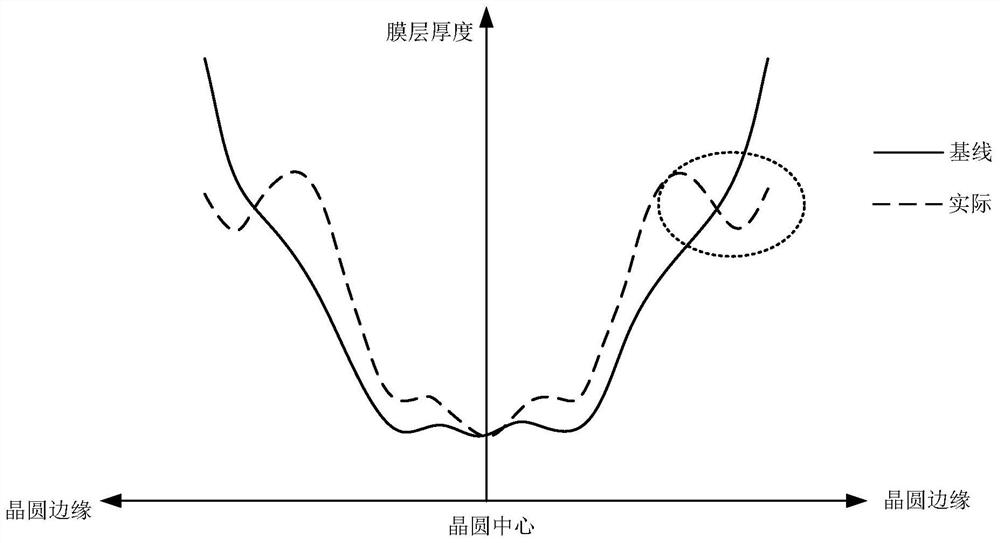

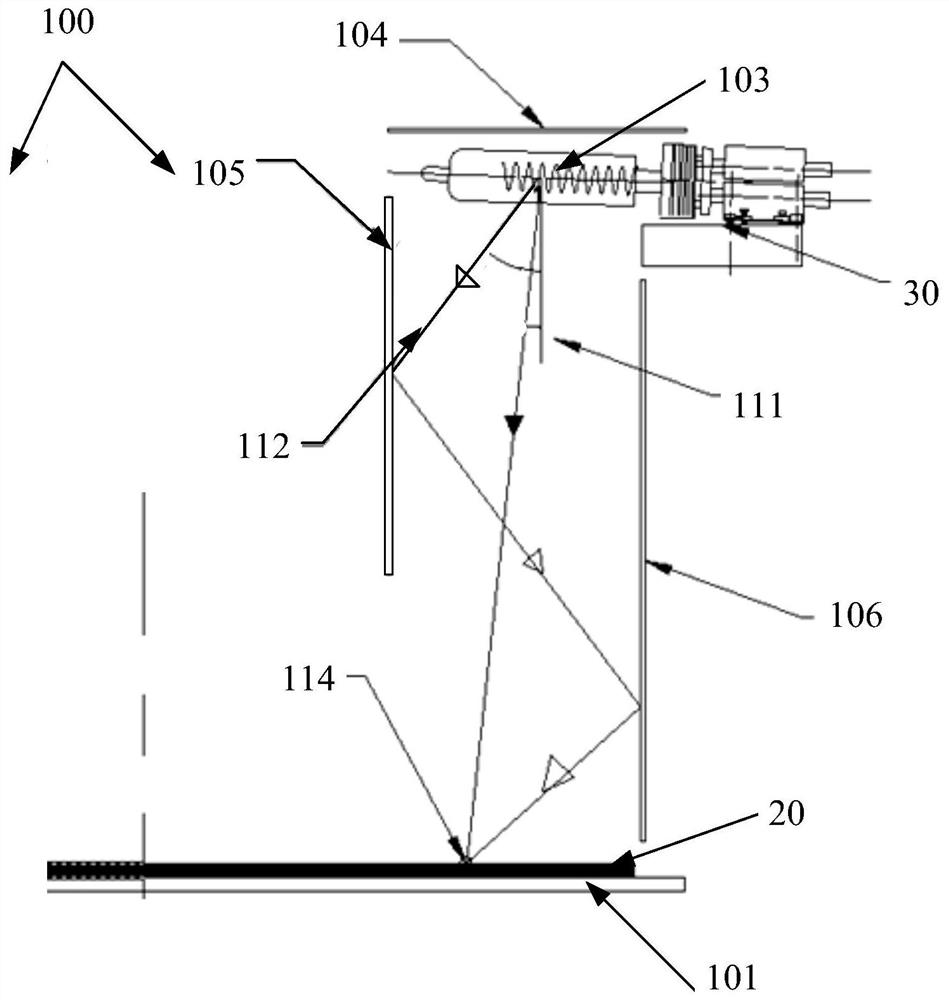

[0031] Silicon germanium (SiGe) is an important semiconductor material after silicon and gallium arsenide. It has better characteristics than pure silicon and is compatible with silicon in process. At the same time, the cost of silicon germanium is lower than that of gallium arsenide. , but the performance of devices and circuits made of silicon germanium can almost reach the level of compound semiconductor devices and circuits such as gallium arsenide. Therefore, silicon germanium technology has become an important direction for the development of microelectronics technology, and in many devices In the manufacturing process of the silicon germanium film layer, it needs to be realized by the epitaxial growth process. A commonly used epitaxial growth equipment for epitaxial growth of SiGe film, such as Figure 1A As shown, it includes a reaction chamber 100, a wafer carrying base 101, a fixed lamp socket (lamp sockets) 102, a heating lamp group (outer lamp & inner lamp) 103, a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com