A device and method for preparing bio-crude oil by continuous hydrothermal liquefaction of biomass

A technology of bio-crude oil and hydrothermal liquefaction, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, chemical/physical/physicochemical processes, etc., can solve the problems of difficult product separation and high cost, and achieve cost reduction and low cost , Improve the effect of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

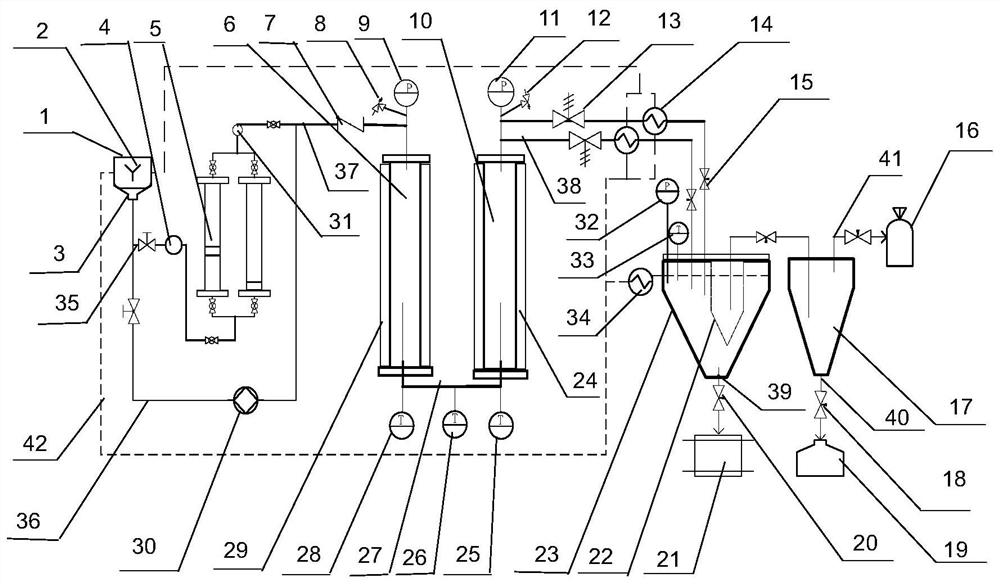

Image

Examples

Embodiment 1

[0108] The device for preparing bio-crude oil by continuous hydrothermal liquefaction of biomass of the present invention is used to process microalgae materials. Among them, the moisture content of the biomass of the microalgae material is 80%, the reaction temperature of hydrothermal liquefaction is 285°C, the system pressure is 9.0MPa, and the reaction time is 20 minutes. After 10 hours of stable operation of the reactor, 52.0% of crude oil can be obtained. The state is stable, and the fluctuation range of temperature and pressure is not obvious.

Embodiment 2

[0110] The device for preparing bio-crude oil by biomass continuous hydrothermal liquefaction of the present invention is used to process animal feces materials. Among them, the water content of animal manure is 86%, the reaction temperature of hydrothermal liquefaction is 300°C, the system pressure is 10.8MPa, and the reaction time is 30 minutes. After 10 hours of stable operation of the reactor, 60.2% of crude oil can be obtained, and the operation state is stable. The fluctuation range of temperature and pressure is not obvious.

Embodiment 3

[0112] The device for preparing bio-crude oil by biomass continuous hydrothermal liquefaction of the present invention is used to process kitchen waste materials. Among them, the water content of kitchen waste is 89%, the reaction temperature of hydrothermal liquefaction is 320°C, the system pressure is 12.8MPa, and the reaction time is 45 minutes. After 8 hours of stable operation of the reactor, 59.2% of crude oil can be obtained. Stable, temperature and pressure fluctuation range is not obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com