Preparing method of toughened carbon fiber resin-based composite

A carbon fiber resin matrix and composite material technology is applied in the field of preparation of toughened carbon fiber resin matrix composite materials, which can solve the problems of high production cost, complexity, environmental pollution, etc., and achieve improved mechanical properties, simple preparation process, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

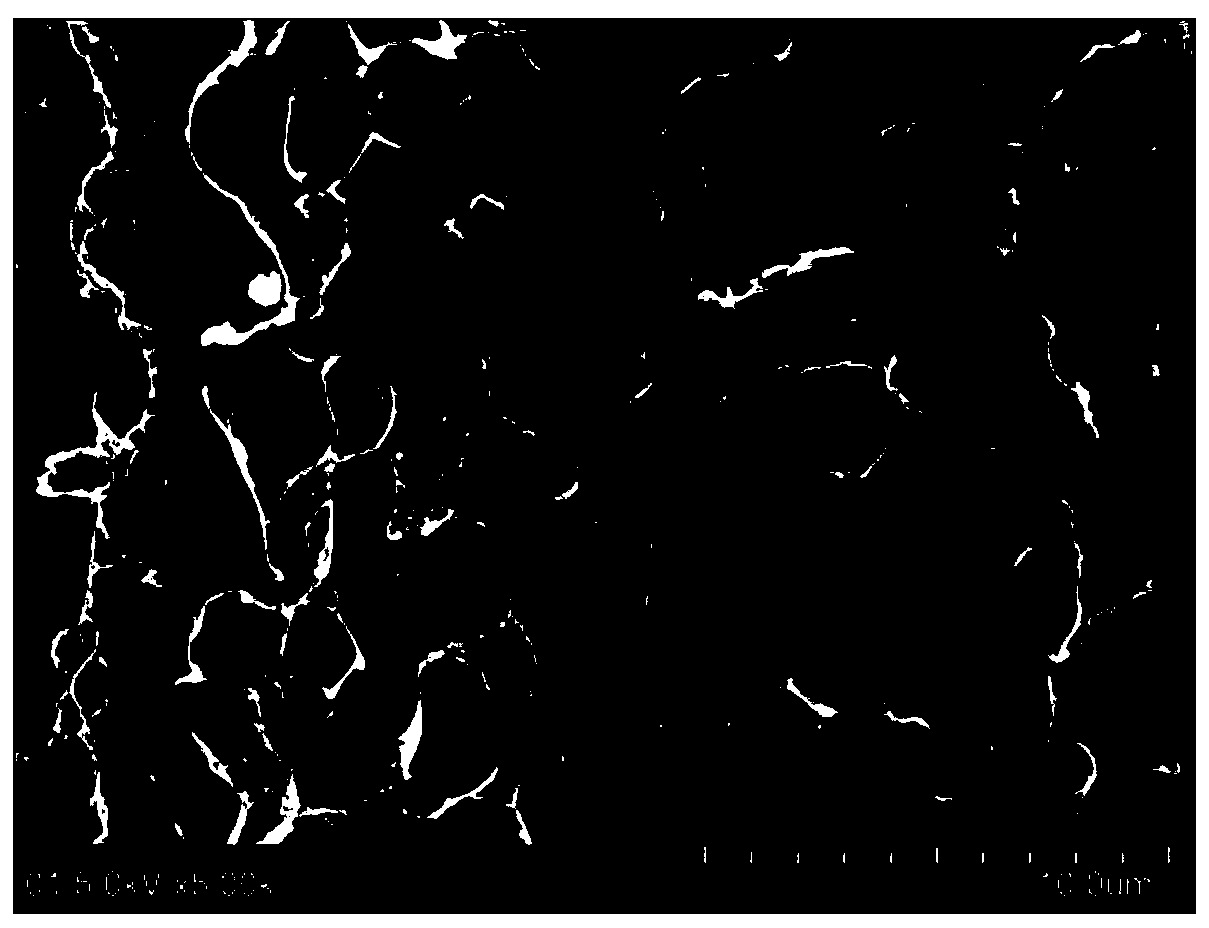

Image

Examples

Embodiment 1

[0042] (1) Take 70g of polyethersulfone and put it into a blender, add 30g of E51 epoxy resin, and mechanically blend to obtain a blend.

[0043] (2) Add the obtained blend into twin-screws for melt spinning, and collect the spun fibers into rolls through a winder, and collect them for use.

[0044] (3) Slowly unwind the obtained fiber roll onto a winding drum, and then put it into a 160° C. oven for heat setting for 10 minutes.

[0045] (4) Put the fiber net between the continuous carbon fiber cloth layers, lay carbon fiber cloth, release cloth, diversion net, and vacuum bag to seal the whole system according to the VARI process. Then, the gas in the mold cavity was pumped out under vacuum negative pressure, and E51 epoxy resin was poured at 60°C. The resin viscosity was 0.2Pa·s, and the ratio of composite mold to carbon fiber cloth layers was 9:11. Curing at 120° C. for 2 hours, and then curing at 180° C. for 1 hour (the curing agent is E100 DETDA) to obtain a polyethersulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com