Method for absorbing impurity B in silicon by using oxygen-containing porous layer

A technology of porous layer and porous silicon, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of unsatisfactory removal, large segregation coefficient, difficult separation, etc., and achieve novel preparation route, simple process, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1. A method for absorbing impurity B in silicon by using an oxygen-containing porous layer, carried out according to the following steps:

[0023] a) Crushing of silicon block: make silicon block into 120-mesh metallurgical-grade silicon powder; the specific preparation is: first crush metallurgical-grade silicon to millimeter-sized particles, then use a planetary ball mill for 120 minutes, and filter through a 120-mesh sieve;

[0024] Afterwards, silicon powder pretreatment: use 2mol / L H 2 SO 4 and H 2 o 2 The mixed solution, 2mol / L HF solution, absolute ethanol and pure water were stirred and washed with a magnetic stirrer for 25 min, filtered, and dried in a vacuum oven;

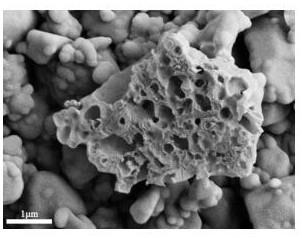

[0025] b) Preparation of porous silicon: Corrode the pretreated silicon powder with corrosion solution at high temperature: put 10g of silicon powder into a plastic beaker, pour 5mol / L HF, 0.03mol / L Fe(NO 3 ) 3 The mixed solution was kept in an agitated water bath at 80°C for 120 minu...

Embodiment 2

[0030] Example 2. A method for absorbing impurity B in silicon by using an oxygen-containing porous layer, carried out according to the following steps:

[0031] a) Crushing of silicon block: make silicon block into 120-mesh metallurgical-grade silicon powder; the specific preparation is: first crush metallurgical-grade silicon to millimeter-sized particles, then use a planetary ball mill for 120 minutes, and filter through a 120-mesh sieve;

[0032] Afterwards, silicon powder pretreatment: use 2mol / L H 2 SO 4 and H 2 o 2 The mixed solution, 2mol / L HF solution, absolute ethanol and pure water were stirred and washed with a magnetic stirrer for 25 min, filtered, and dried in a vacuum oven;

[0033] b) Preparation of porous silicon: Corrode the pretreated silicon powder with corrosion solution at high temperature: put 10g into the liner of the hydrothermal kettle, pour 5mol / L HF, 0.03mol / L Fe(NO 3 ) 3 The mixed solution was kept in a 150°C hydrothermal kettle for 300min; ...

Embodiment 3

[0038] Example 3. A method for absorbing impurity B in silicon by using an oxygen-containing porous layer, carried out according to the following steps:

[0039] a) Crushing of silicon block: make silicon block into 120-mesh metallurgical-grade silicon powder; the specific preparation is: first crush metallurgical-grade silicon to millimeter-sized particles, then use a planetary ball mill for 120 minutes, and filter through a 120-mesh sieve;

[0040] Afterwards, silicon powder pretreatment: use 2mol / L H 2 SO 4 and H 2 o 2 The mixed solution, 2mol / L HF solution, absolute ethanol and pure water were stirred and washed with a magnetic stirrer for 25 min, filtered, and dried in a vacuum oven;

[0041] b) Preparation of porous silicon: Corrode the pretreated silicon powder with corrosion solution at high temperature: put 10g into the liner of the hydrothermal kettle, pour 5mol / L HF, 0.03mol / L Fe(NO 3 ) 3The mixed solution was kept in a 150°C hydrothermal kettle for 300min;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com