Non-slip sheet for shoe sole and preparation method of non-slip sheet

A technology for anti-slip sheets and soles, which is applied in the field of sole materials, can solve the problems such as the decline of anti-slip performance of soles, and achieve the effects of long service life, good wear resistance and good anti-slip performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

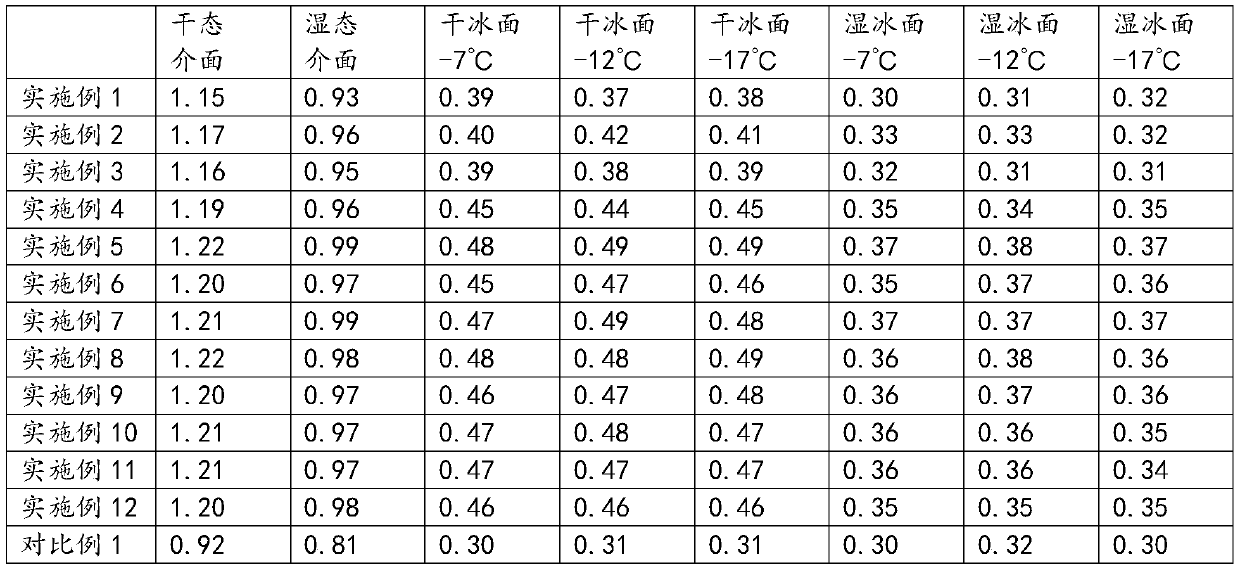

Examples

Embodiment 1

[0040] An anti-slip sheet for shoe soles, comprising the following components in parts by weight: 3 parts of isoprene rubber, 18 parts of styrene-butadiene rubber, 10 parts of butadiene rubber, 10 parts of white carbon black, 1 part of white mineral oil, alkali 2 parts of zinc carbonate, 1.5 parts of active agent, 0.2 part of stearic acid, 0.1 part of antifogging agent, 0.59 part of accelerator, 0.5 part of vulcanizing agent, 0.2 part of glass fiber, and 0.5 part of anti-aging agent.

[0041] Among them, 1.5 parts of active agent includes 1.3 parts of PEG-4000 active agent and 0.2 part of DEG active agent.

[0042] Among them, 0.59 parts of accelerators include 0.5 parts of DM accelerators, 0.05 parts of D-80 accelerators, and 0.04 parts of TMTM rubber accelerators.

[0043] Wherein, 0.5 part of anti-aging agent includes 0.4 part of BHT anti-aging agent and 0.1 part of MB anti-aging agent.

[0044]The preparation method comprises the following preparation steps:

[0045] S1,...

Embodiment 2

[0051] An anti-slip sheet on ice comprises the following components in parts by weight: 5 parts of isoprene rubber, 21 parts of styrene-butadiene rubber, 15 parts of butadiene rubber, 12 parts of white carbon black, 2 parts of white mineral oil, basic carbonic acid 2.2 parts of zinc, 1.6 parts of active agent, 0.3 part of stearic acid, 0.1 part of anti-fog agent, 0.66 part of accelerator, 0.6 part of vulcanizing agent, 0.23 part of glass fiber, and 0.6 part of anti-aging agent.

[0052] Among them, 1.6 parts of active agent includes 1.3 parts of PEG-4000 active agent and 0.3 part of DEG active agent.

[0053] Among them, 0.66 parts of accelerators include 0.5 parts of DM accelerators, 0.1 parts of D-80 accelerators, and 0.06 parts of TMTM rubber accelerators.

[0054] Wherein, 0.5 part of antiaging agent includes 0.4 part of BHT antiaging agent and 0.2 part of MB antiaging agent.

[0055] The preparation method comprises the following preparation steps:

[0056] S1, prepare ...

Embodiment 3

[0062] An anti-slip sheet on ice, comprising the following components in parts by weight: 6 parts of isoprene rubber, 25 parts of styrene-butadiene rubber, 14 parts of butadiene rubber, 15 parts of white carbon black, 2 parts of white mineral oil, alkali 3 parts of zinc carbonate, 1.6 parts of active agent, 0.4 part of stearic acid, 0.2 part of antifogging agent, 0.73 part of accelerator, 0.7 part of vulcanizing agent, 0.3 part of glass fiber, and 0.7 part of anti-aging agent.

[0063] Among them, 1.6 parts of active agent includes 1.3 parts of PEG-4000 active agent and 0.4 part of DEG active agent.

[0064] Among them, 0.73 parts of accelerators include 0.5 parts of DM accelerators, 0.15 parts of D-80 accelerators, and 0.08 parts of TMTM rubber accelerators.

[0065] Wherein, 0.5 part of antiaging agent includes 0.4 part of BHT antiaging agent and 0.3 part of MB antiaging agent.

[0066] The preparation method comprises the following preparation steps:

[0067] S1, prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com