Cutting tool composite coating and preparing method thereof

A composite coating and cutting tool technology, applied in the field of cutting tool coating, can solve problems such as coating peeling, film collapse, and low tool yield, and achieve the effect of relieving interlayer stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

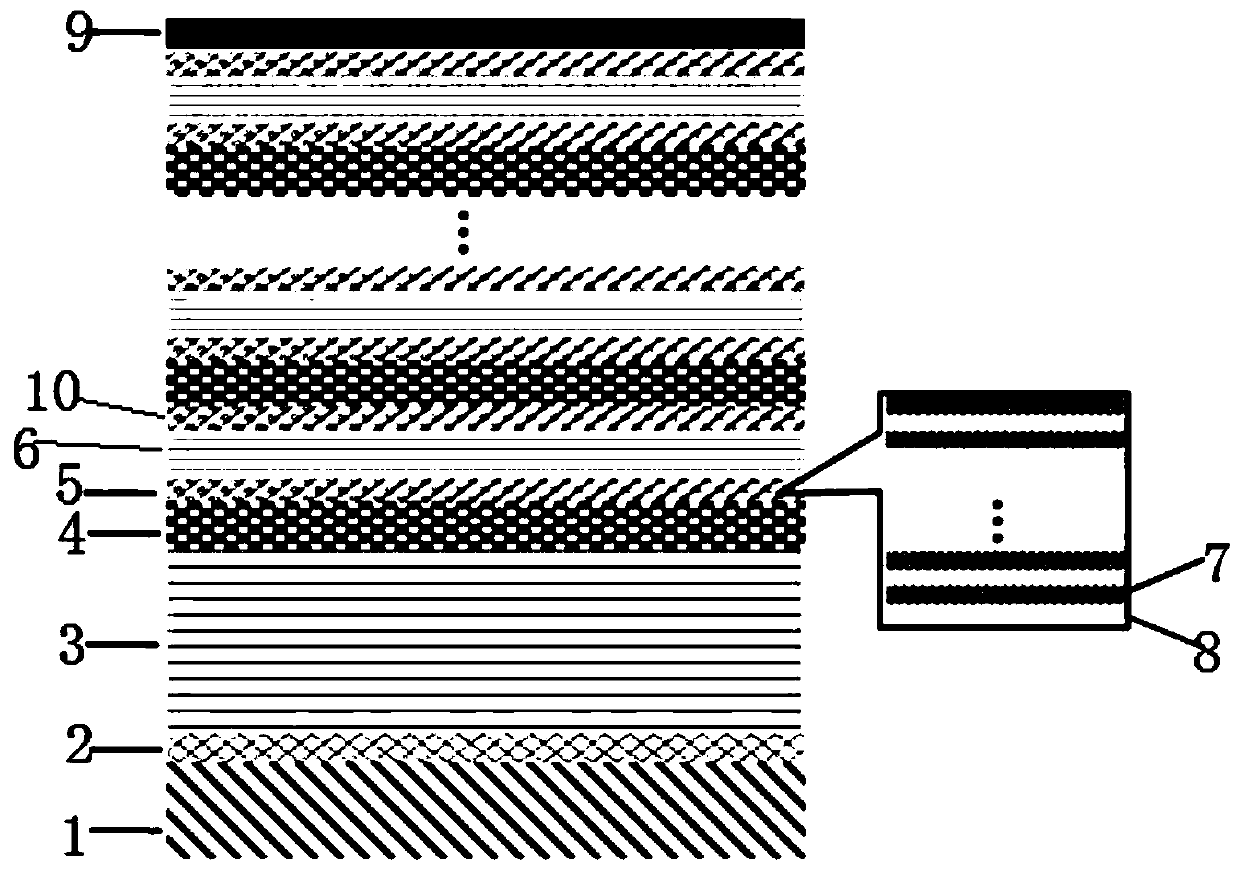

[0034] In some embodiments, the method for preparing a composite coating for a cutting tool includes the following steps:

[0035]1) A primer layer 2 and a TiAlN transition layer 3 are sequentially deposited on the surface of the cutting tool base layer by a multi-arc ion plating process;

[0036] 2) A functional layer is deposited on the surface of the TiAlN transition layer 3, specifically, a TiAlN monolayer 4, a TiAlN / TiSiN nanocomposite layer 5, a TiSiN monolayer 6 and a TiAlN / TiSiN nanocomposite layer 10 are sequentially deposited on the surface of the TiAlN transition layer 3 as The functional layer of a cycle cycle includes 5-20 cycle cycles; (TiAlN single layer 4, TiAlN / TiSiN nanocomposite layer 5, TiSiN single layer 6, TiAlN / TiSiN nanocomposite layer 10 is a cycle cycle, a total cycle of 5- 20 times).

[0037] In some embodiments, the primer layer 2 is TiN, CrN or ZrN, the thickness of the primer layer 2 is 50-300nm, the TiAlN transition layer 3 is deposited on the s...

Embodiment 1

[0042] Use the cemented carbide blade of YG8 material as the substrate, first clean the blade with an industrial cleaning line, then put it into the coating machine, evacuate it to below 5e-4mBar, heat it to 400°C and etch the surface of the blade with Ar ions. A 200nm thick TiN layer and a 500nm thick Ti layer are sequentially deposited on the blade by a multi-arc ion plating process 0.6 Al 0.4 N transition layer, and then deposit the functional layer according to the method of "TiAlN single layer-TiAlN / TiSiN nanocomposite layer-TiSiN single layer-TiAlN / TiSiN nanocomposite layer". During the deposition of the functional layer, the TiAl target is first opened to deposit 50nm Ti 0.6 Al 0.4 N layer, then turn on the TiAl target and TiSi target at the same time, and deposit 50nm Ti 0.6 Al 0.4 N and Ti 0.7 Si 0.3 A composite layer of N, and then close the TiAl target to deposit Ti with a thickness of 60 nm 0.7 Si 0.3 N layer, and then turn on the TiAl target and TiSi target...

comparative example 1

[0044] Use the cemented carbide blade of YG8 material as the substrate, first clean the blade with an industrial cleaning line, then put it into the coating machine, evacuate it to below 5e-4mBar, heat it to 400°C and etch the surface of the blade with Ar ions. A 200nm thick TiN layer and a 500nm thick Ti layer are sequentially deposited on the blade by a multi-arc ion plating process 0.6 Al 0.4 N transition layer, functional layer uses TiSi target to deposit Ti with a thickness of 3.0um 0.7 Si 0.3 N single-layer coating, the total thickness of the coating is about 3.7μm. The hardness of the coating obtained by this method is 4300-4500HV, the scratch adhesion is less than 60N, and it is easy to peel off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com