Conductive spraying powder and preparation method thereof, preparation system of conductive spraying powder and use method of conductive spraying powder

A technology of spraying powder and conductive powder, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. It can solve problems such as agglomeration and easy agglomeration of powder coatings, and achieve simple preparation process, Easy to promote and reduce the effect of agglomeration and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

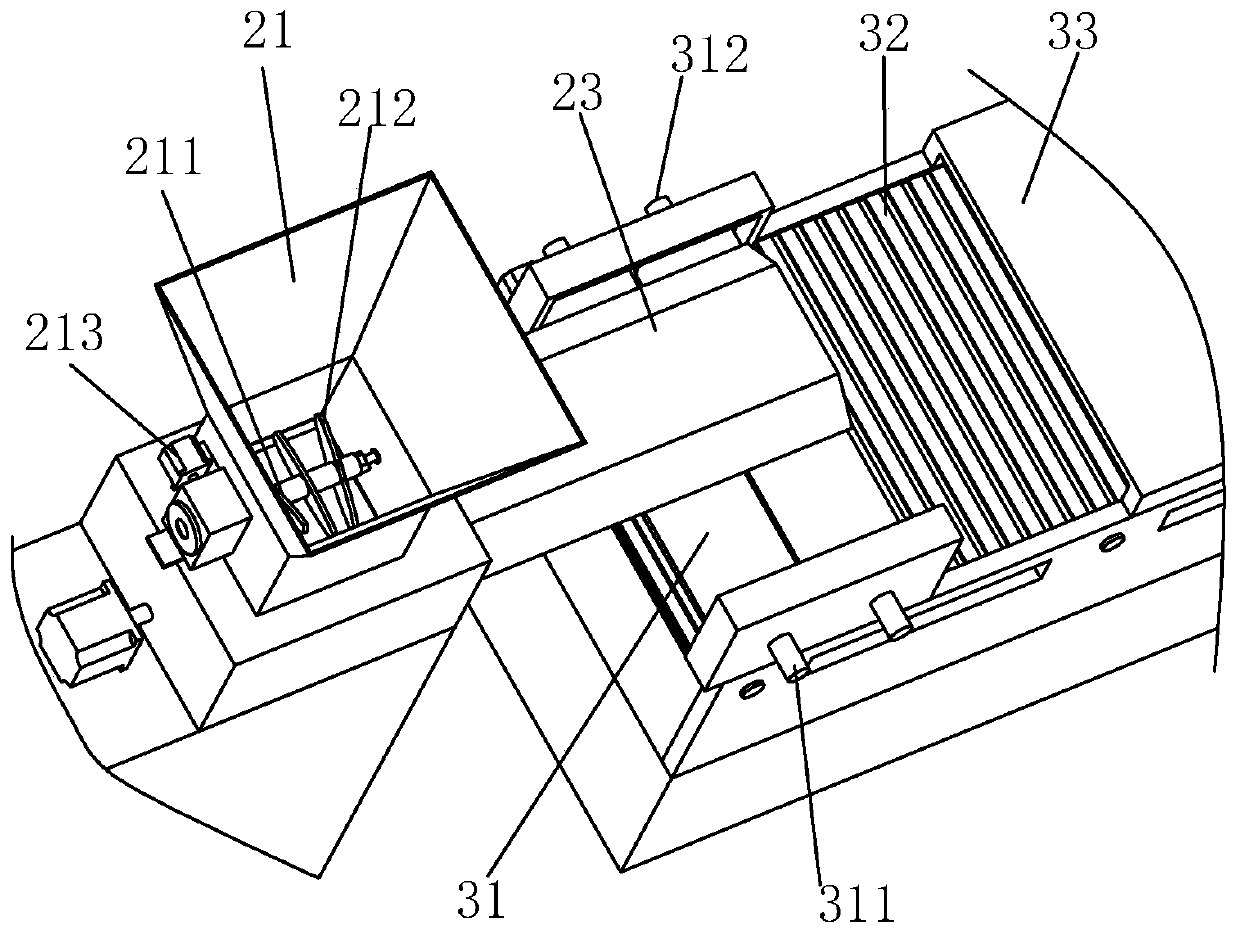

[0072] The preparation technology of conductive spraying powder comprises the following steps:

[0073] (1) Premixing, mixing the raw materials other than aluminum oxide evenly;

[0074] (2) Mixing and extruding, put the uniformly mixed raw materials into the extruder for mixing, the temperature of the melting section is 115±5°C, the temperature of the mixing section is 105±5°C, and the mixture fluid is extruded;

[0075] (3) Cooling, cooling the extruded mixture fluid to room temperature to form a solid mixture;

[0076] (4) Crushing, coarsely crushing the solid obtained in step (3) into particles with a particle size of 0.5-1 cm; then finely grinding it into powder; and sieving to obtain a powder coating with a particle size of 20-35 μm.

[0077] After fine processing and grinding into powder in step (4), add Al2O3 powder before sieving.

[0078] The use method of conductive spray powder comprises the following steps:

[0079] Step 1. Evenly spray the conductive spray pow...

Embodiment 6

[0082] Conductive spraying powder, the difference between embodiment 6 and embodiment 4 is that 10% Al(OH) is also added in the auxiliary agent 3 ;Al(OH) 3 The purity of the powder is greater than 99.5%, the particle size is below 3000 mesh, and the particle size of the prepared powder coating is 20-35 μm.

Embodiment 7

[0084]Conductive spray powder, the difference between embodiment 7 and embodiment 4 is that the auxiliary agent contains 5% by weight of bentonite, and the rest is barium sulfate and pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com