Modified starch for baking dough

A technology for modified starch and pastry, applied in the field of starch processing, can solve the problems of difficulty in forming dough, sticky dough, no elasticity, etc., and achieve the effects of strong water retention, increased freshness and good volume of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A modified starch for baked pastries, comprising the following steps:

[0020] Step 1. Mix tapioca starch with water and stir evenly. The mass ratio of starch to water is 2:3. Add hydrogen peroxide and stir for 30 minutes;

[0021] Step 2, dilute caustic soda to adjust the pH to 12, keep warm at 40°C, add propylene oxide, and react for 48 hours;

[0022] Step 3, raise the temperature to 45°C, add dilute acid to adjust the pH to 10.5, then add sodium trimetaphosphate, and react for 3 hours;

[0023] Step 4: Add dilute acid to adjust the pH to 5.7, swirl washing, dehydration and drying, and fully mix with pregelatinized starch at a ratio of 9:1 before packaging.

[0024] In addition, the pregelatinized starch in step 4 is prepared by the following steps:

[0025] ①Control the quality of raw materials: select fresh potatoes with a protein content of 1.5%-1.8% and an ash content of 0.3%-0.4%;

[0026] ② Add deionized water to the potato raw materials, and mix lactic acid...

Embodiment 2

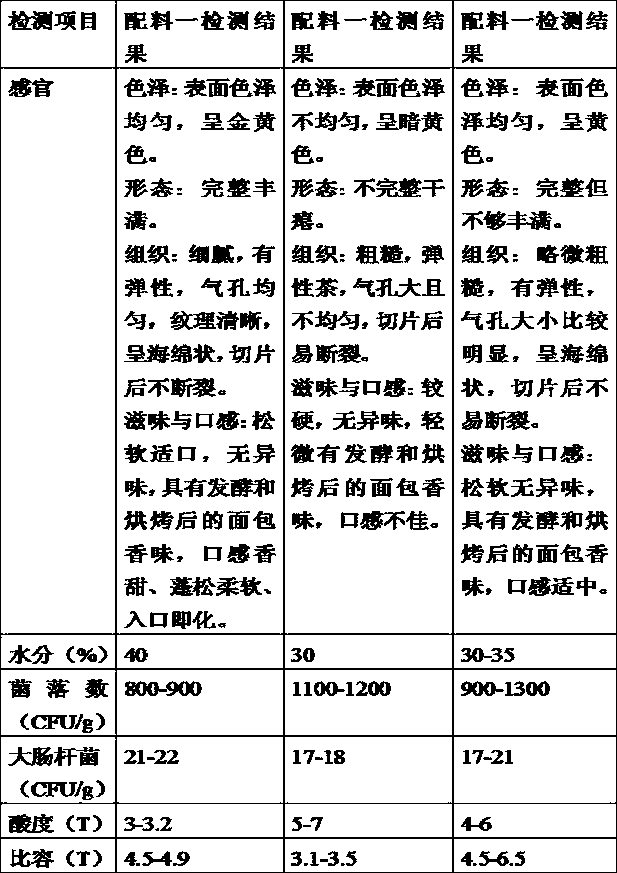

[0028] Embodiment 2 Experimental comparison

[0029] Ingredients 1 (contains modified starch for baked pastries in Example 1):

[0030] 200 parts of water

[0031] 50 parts of egg liquid

[0032] 55 parts fine sugar

[0033] 200 parts of high-gluten flour

[0034] 20 parts of modified starch for the above baked pastries

[0035] 4 parts salt

[0036] 4 parts yeast

[0037] 30 parts of butter

[0038] Production Method:

[0039] ①Put the liquid (water, eggs) into the bread bucket first, stir well, then add salt and sugar, then add high-gluten flour and modified starch for baking pastries of the present invention, poke a small hole in the flour and put yeast, and knead the dough for 15 minutes .

[0040] ②After kneading the dough, add softened butter and ferment at 28°C for 2 hours.

[0041] ③ After the dough is fermented, it is sent to the bread machine to be processed into bread.

[0042] Ingredients 2 (excluding modified starch and other pregelatinized starches for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com