Light wide-frequency wave-absorbing material based on impedance metamaterial and preparation method of light wide-frequency wave-absorbing material

A technology of wave absorbing materials and metamaterials, applied in the field of wave absorbing materials, can solve the problems of narrow absorption frequency band, large thickness and large weight, and achieve the effect of absorbing broadband, thin thickness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In a first aspect, the present invention provides a method for preparing a lightweight broadband absorbing material based on impedance metamaterials, the method comprising the following steps:

[0030] (1) carbon nanotube powder is dispersed in the resin solution, is mixed with carbon nanotube slurry, then said carbon nanotube slurry is scraped on the polyimide film, obtains carbon nanotube coating film; In the present invention, the carbon nanotube slurry is scraped on the polyimide film to form a carbon nanotube coating film with certain resistance; in the present invention, the carbon nanotube coating film is made of polyimide A film and a carbon nanotube film are composed; the carbon nanotube film is formed by scraping the carbon nanotube slurry on the polyimide film (substrate);

[0031] (2) Etching (such as laser etching) a periodic structure composed of multiple (two and more) periodic structural units on the carbon nanotube coating film obtained in step (1), to ...

Embodiment 1

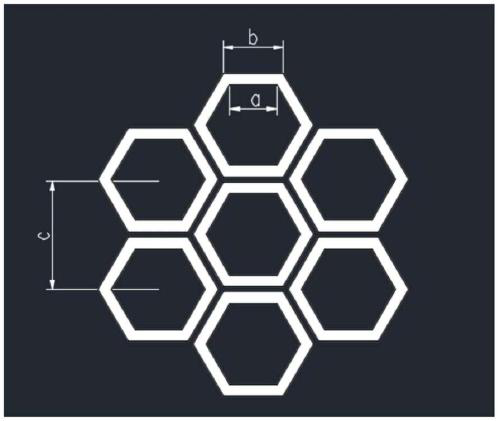

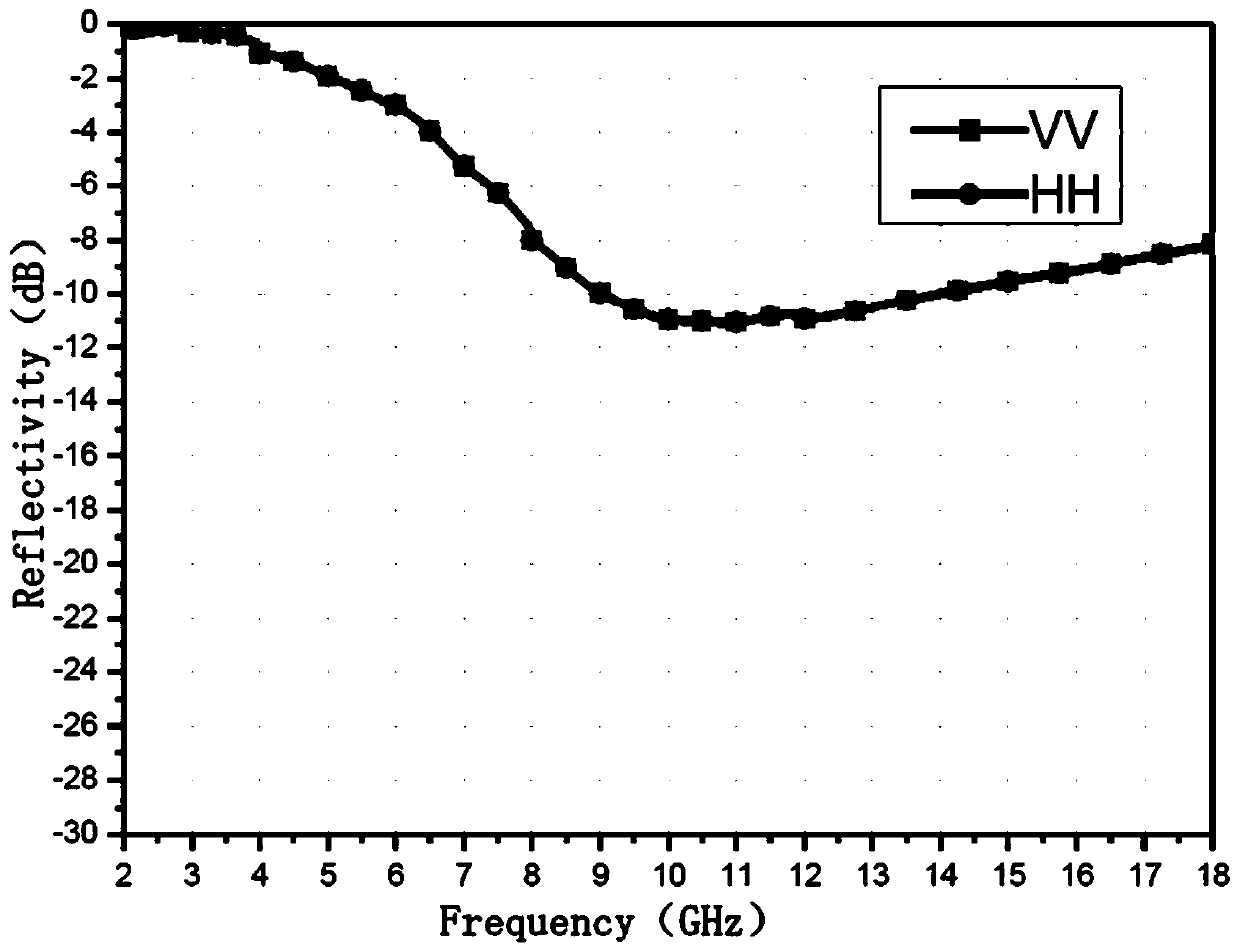

[0059] A lightweight broadband radar absorbing material based on impedance metamaterials is prepared. The lightweight broadband absorbing material is composed of impedance metamaterials and low-dielectric dielectric films, and has a two-layer structure, such as figure 1 As shown; the first layer is an impedance metamaterial with a thickness of d1 = 0.13mm, and the second layer is a low-dielectric film, the low-dielectric material used is polymethacrylimide PMI with a thickness of d2 = 4mm. Among them, the impedance metamaterial is to etch a periodic structure on the carbon nanotube coating film, the periodic structural unit is a regular hexagon, and the periodic structural unit and the formed periodic structural pattern are as follows: figure 2 As shown, a=3.7mm, b=4.75mm, c=8.66mm.

[0060] The preparation process of the lightweight broadband radar absorbing material based on impedance metamaterials is as follows:

[0061] S1. Preparation of carbon nanotube slurry

[0062]...

Embodiment 2

[0071] A lightweight broadband radar absorbing material based on impedance metamaterials is prepared. The lightweight broadband absorbing material is composed of impedance metamaterials and low-dielectric dielectric films, and has a two-layer structure, such as figure 1 As shown; the first layer is an impedance metamaterial with a thickness of d1 = 0.13mm, and the second layer is a low-dielectric film. The low-dielectric material used is polymethacrylimide PMI with a thickness of d2 = 8mm. Among them, the impedance metamaterial is to etch a periodic structure on the carbon nanotube coating film, the periodic structural unit is a regular hexagon, and the periodic structural unit and the formed periodic structural pattern are as follows: figure 2 As shown, a=3.7mm, b=4.75mm, c=8.66mm.

[0072] The preparation process of the lightweight broadband radar absorbing material based on impedance metamaterials is as follows:

[0073] S1. Preparation of carbon nanotube slurry

[0074] W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com