Partitioned crucible melt out-of-pile catcher

A melt and trap technology, applied in the field of reactor safety system design, can solve problems such as poor cooling effect of melt, long melt migration path, large layout space, etc., to eliminate the risk of steam explosion and improve long-term safety , the effect of strengthening the heat exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

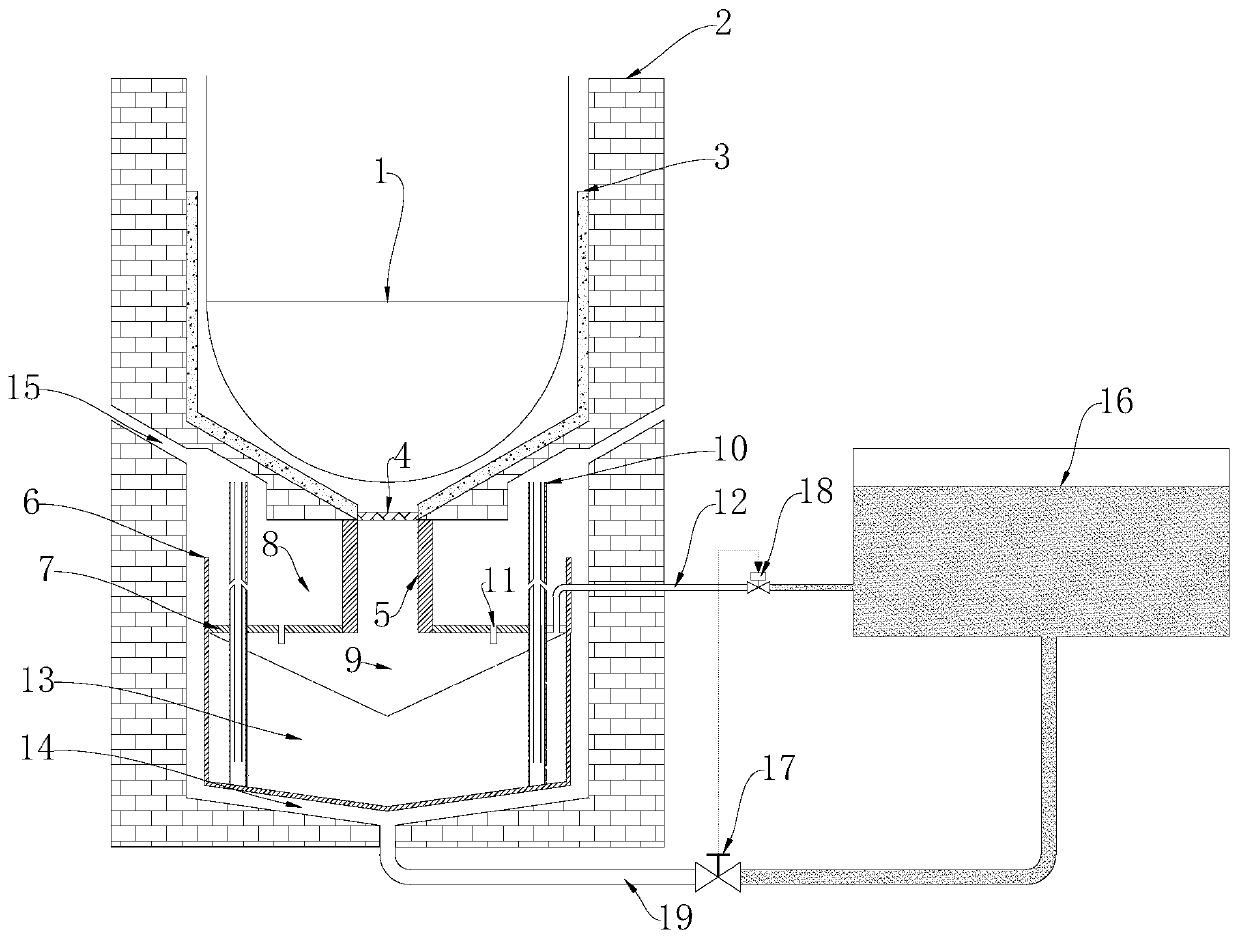

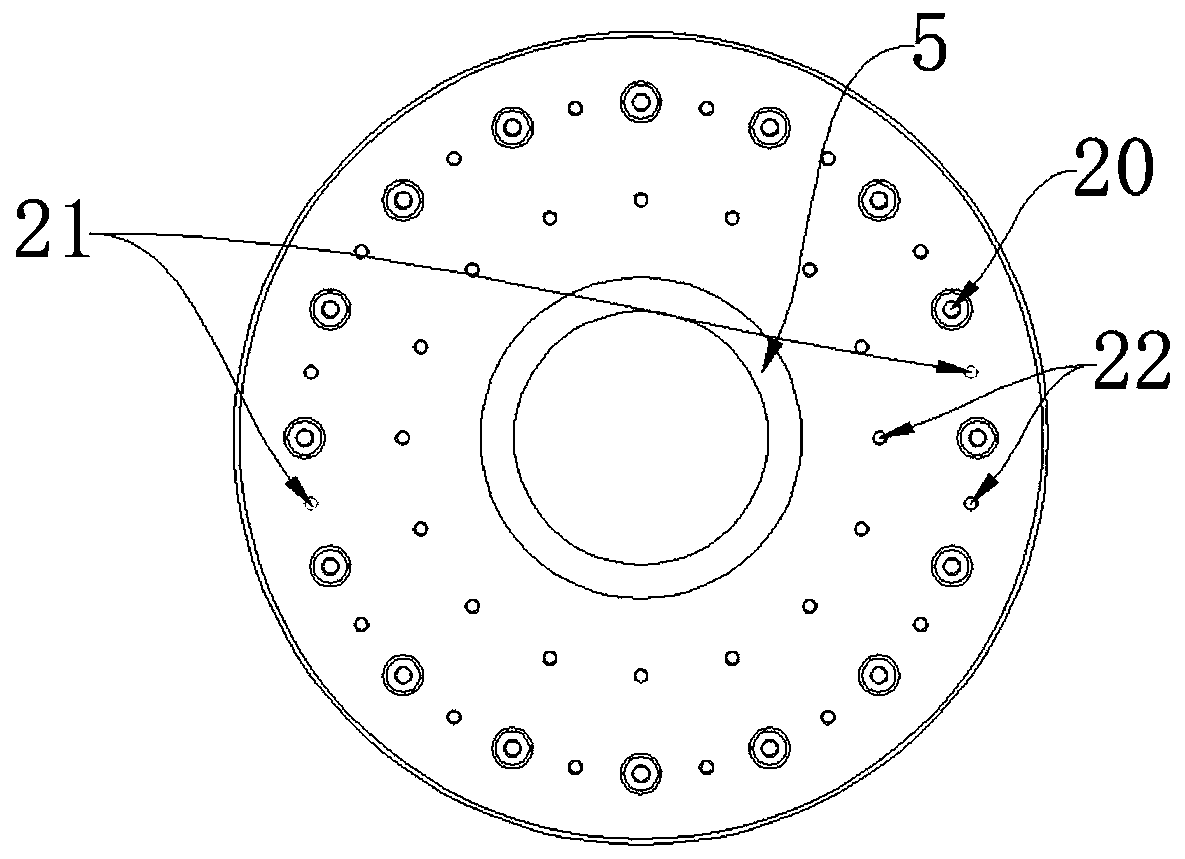

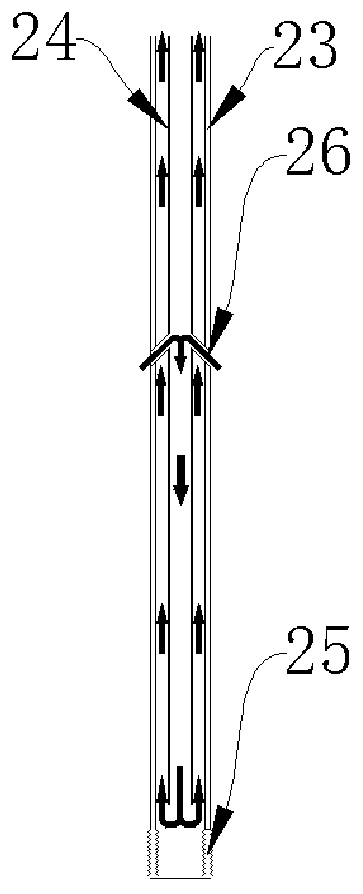

[0035] Such as figure 1 As shown, the present invention provides a catcher outside the heap of the crucible molten material in partitions, comprising a molten material transfer channel 5, a molten material collecting crucible 6 and a cooling water tank 16; the inner wall surface of the bottom of the pile pit 2 is covered with a refractory material 3; The passage 5 connects the pile pit 2 and the melt collection crucible 6; the melt transfer passage 5 also includes a fusing plug 4 for blocking the pile pit 2; the melt collection crucible 6 is connected with a cooling water tank 16 . The melt collection crucible 6 includes a partition 7, the melt transfer channel 5 is fixed on the partition 7, the melt transfer channel 5 and the partition 7 jointly divide the melt collection crucible 6 into mutually isolated annular water chambers 8 and Melt cooling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com