Digestion method and digestion device for quickly digesting carbon monoxide

A carbon monoxide and digestion device technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as slow purification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

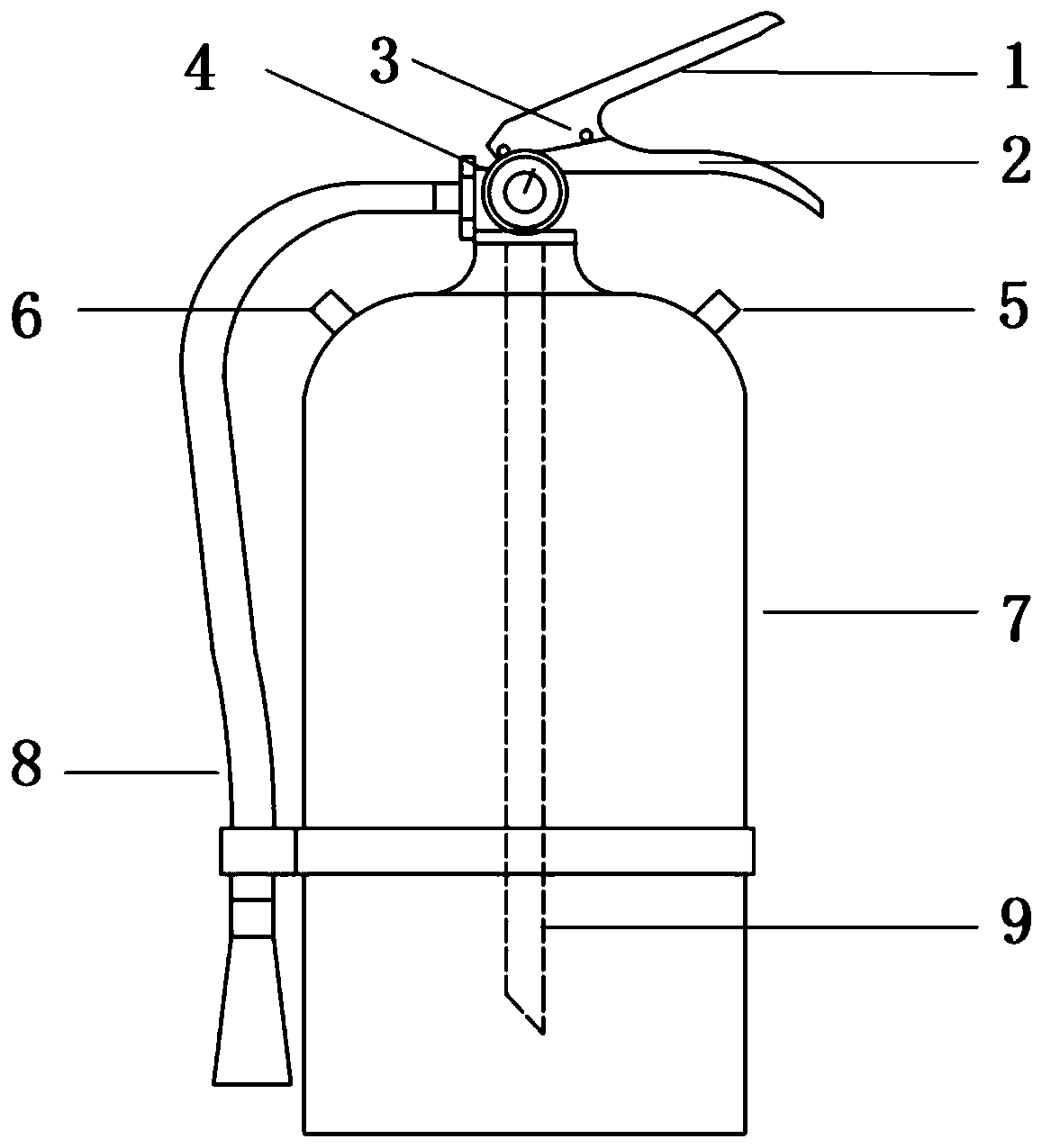

[0040]Example 1: According to the method of rapid digestion of carbon monoxide, a pressure storage type carbon monoxide digestion device is proposed, using manganese and copper composite metal oxide as a catalyst. Before loading the catalyst, grind the catalyst into a powder of more than 100 mesh, and activate it for 1 hour at 200°C in a dry air flow environment; then fill the activated catalyst powder into the storage tank 7, and repeatedly pump it through the vacuum / gas filling port 6 Vacuum and dry air three times each, and finally fill with dry air until the air pressure in the tank reaches 1.5MPa; when using a carbon monoxide digestion device, pull out the limit pin 3 and hold the support ring 2 with one hand. Hold the nozzle 8 with one hand, and operate the pressure rod 1 with the hand holding the support rod, and the nozzle faces the space to be digested to complete the carbon monoxide digestion. The catalyst powder in the catalyst powder storage tank was taken out ever...

Embodiment 2

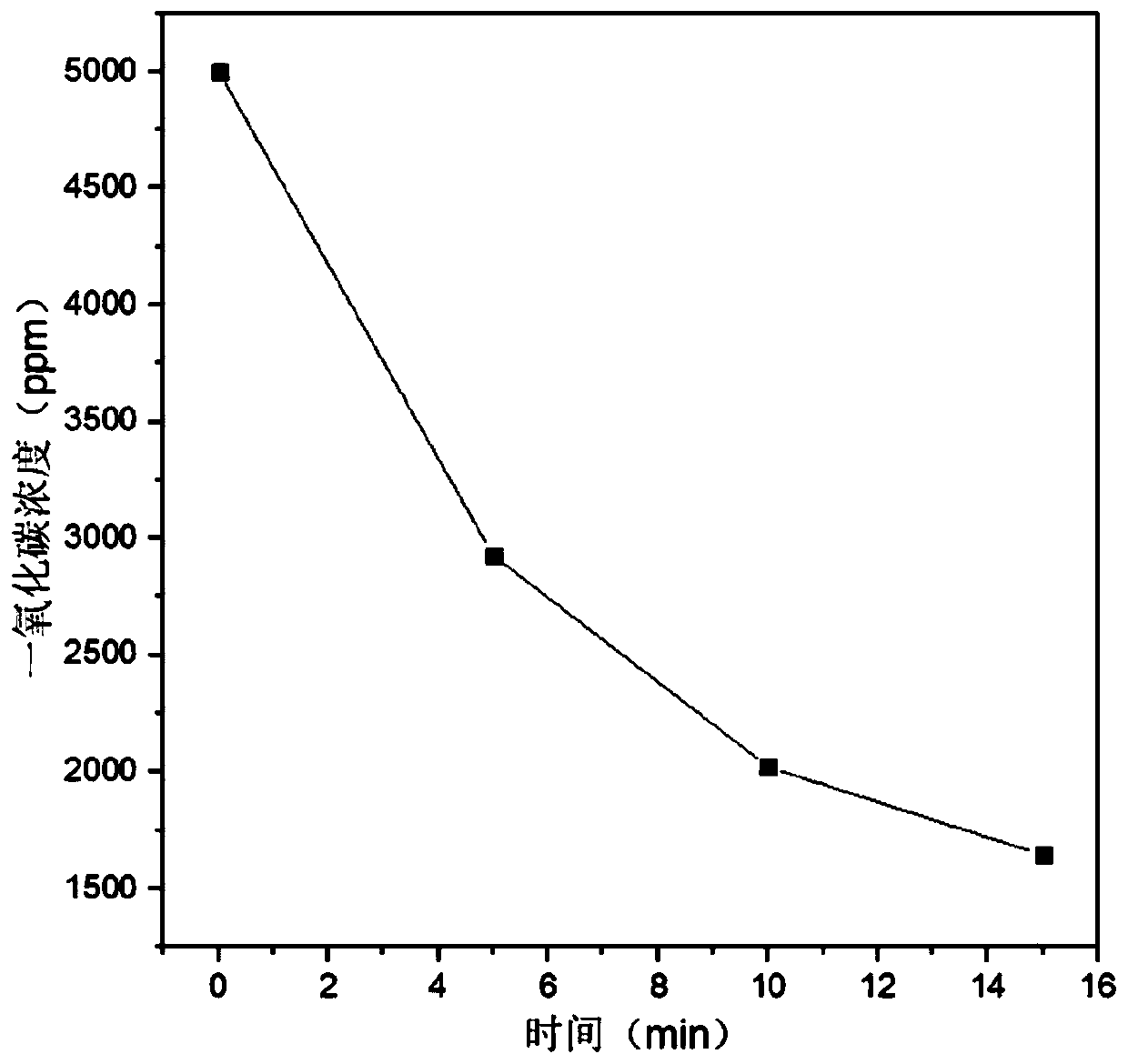

[0041] Example 2: Use a storage pressure carbon monoxide digestion device to digest 0.3m 3 For carbon monoxide in a sealed box (0.5m×0.6m×1m), use catalyst powder with a mass of 0.2kg and a working pressure of 1.5MPa; the concentration of carbon monoxide in the box is 5000ppm, and the ambient temperature is 20°C; use a storage-type carbon monoxide digestion device The catalyst powder is sprayed into the box through the reserved opening (can be sealed); the carbon monoxide concentration change is monitored in real time through the carbon monoxide sensor installed in the box; after the catalyst powder is sprayed, the carbon monoxide concentration in the box continues to drop, and drops to 1700ppm within 15 minutes.

Embodiment 3

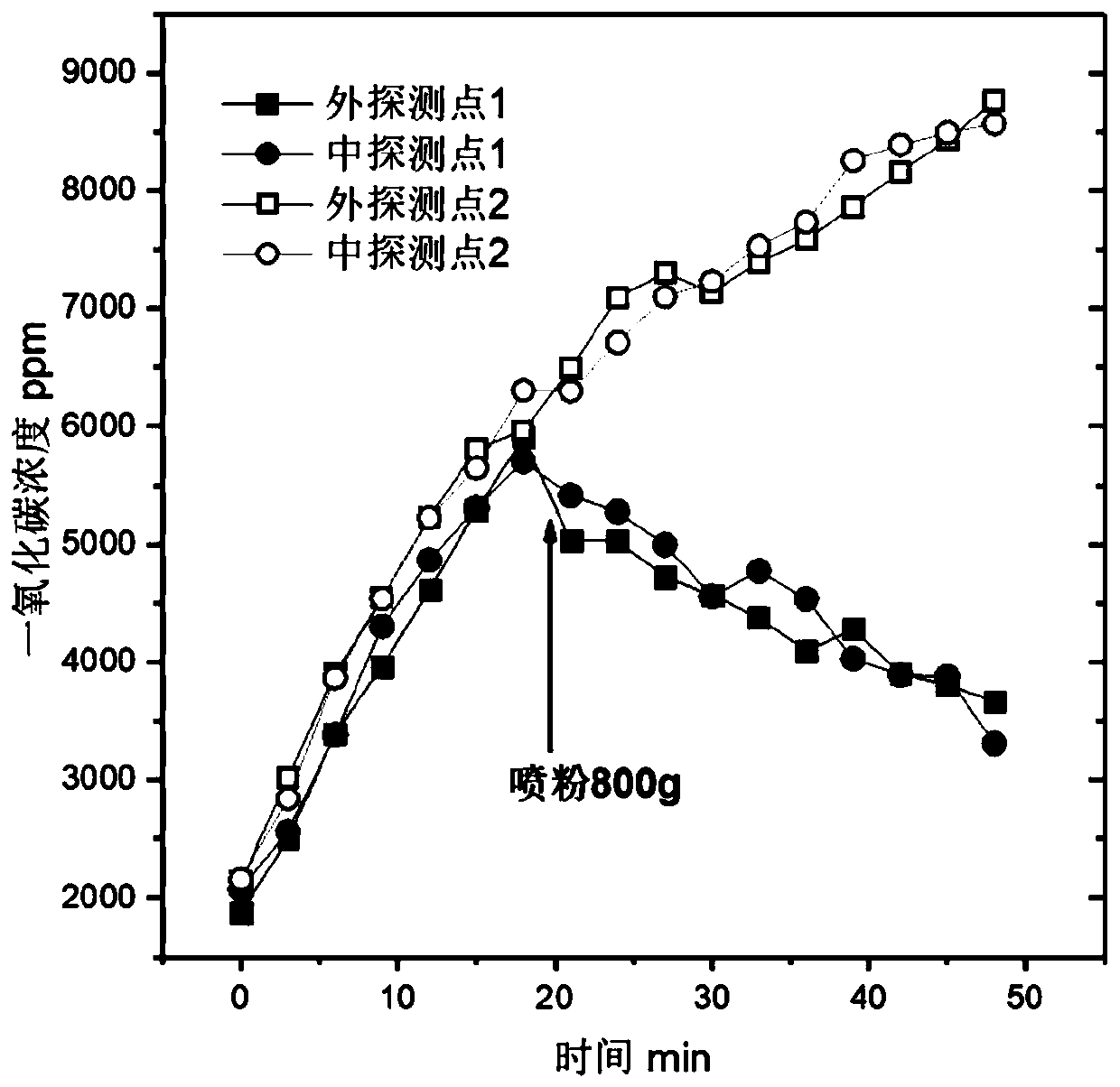

[0042] Example 3: Using a pressure storage type carbon monoxide digestion device to apply to 17.7m 3 Cement pipe gallery (10m in length, 1.5m in diameter), both ends of the pipe gallery are sealed by revolving doors; carbon monoxide is generated by smoldering 7kg of charcoal, the mass of catalyst powder used is 0.8kg, and the working pressure is 1.5MPa; it is installed in the middle of the pipe gallery The reserved opening can be sealed, and the catalyst powder is sprayed into the pipe gallery left and right; since the charcoal is burned, gas sampling is carried out at two preset positions in the pipe gallery every three minutes, and the carbon monoxide concentration is measured by a chromatograph. When no carbon monoxide digestion measures were taken, the carbon monoxide concentration in the pipe gallery continued to rise, reaching 8900ppm within 60 minutes; after using the storage-type carbon monoxide digestion device to spray catalyst powder into the box, the carbon monoxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com