Method for extracting lithium sulfate from lepidolite

A technology of lepidolite and lithium sulfate, which is applied in the direction of lithium sulfate/sulfite, etc., can solve the problems of increasing the loss rate of rare metal materials, reducing the recycling rate of rare metals, and difficulty in meeting the requirements of the mixer. Effects of liquid separation, improvement of process operation efficiency, and reduction of processing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

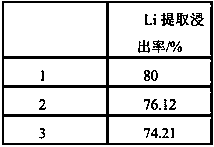

Examples

Embodiment 1

[0039] The present invention discloses a method for extracting lithium sulfate from lepidolite. After mixing lepidolite as raw material and auxiliary materials, the raw material and auxiliary materials are mixed and then roasted in a rotary kiln device to extract lithium, which is as follows Steps: The raw material used in this embodiment is the lepidolite raw material produced by the Yichun Tantalum Niobium Lithium Mine, and its main chemical composition is as shown in Table 1 (wt%) and the remainder is fluorine.

[0040] Table 1 takes the lepidolite raw material produced by Yichun Tantalum Niobium Lithium Mine. Its main chemical composition is as follows (wt%) and the balance is fluorine.

[0041] Li 2 O

K 2 O

Na 2 O

AL 2 O 3

SiO 2

Fe 2 O 3

Rb 2 O

Cs 2 O

5.4510.680.5223.6453.340.311.540.42

[0042] 1) Crush, crush the lepidolite to 50-80 mesh lepidolite powder,

[0043] 2) Mixing, stir and mix the lepidolite powder and roasting auxiliary materials together to form a lep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com