A kind of low-temperature preparation method of nano barium cerate powder

A barium cerate and powder technology is applied in the field of low-temperature preparation of nano-barium cerate powder, which can solve the problems of uncontrollable particle size, uneven particle distribution, large particle size of powder particles, etc. The preparation process is simple and the effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

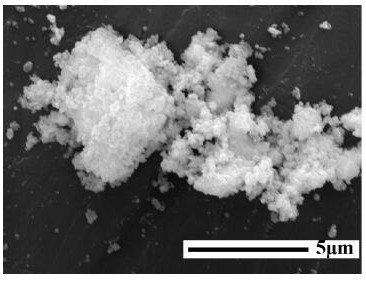

Image

Examples

Embodiment 1

[0023] Example 1. A low-temperature preparation method of nanometer barium cerate powder is prepared according to the following steps:

[0024] A, take by weighing 0.01mol barium nitrate, 0.01mol cerium nitrate, 0.01mol glycerin and 0.015mol PVA respectively;

[0025] B. Add an appropriate amount of PVA to deionized water, and heat it at 98°C to dissolve it, and then prepare a 0.8mol / L PVA solution, add glycerin to it, and stir continuously to prepare an aqueous micellar liquid;

[0026] C. Add barium nitrate and cerium nitrate to the aqueous micellar liquid, and continuously stir the solution on a magnetic stirrer to become a viscous state to obtain a mixed solution;

[0027] D. Heating the mixed solution at 95°C to remove all water until it becomes a jelly-like substance to obtain a jelly-like substance;

[0028] E. Take out the jelly and place it in a pure aluminum oxide crucible, and calcinate it in a muffle furnace at 750°C for 8 hours without pressure. The jelly will r...

Embodiment 2

[0029] Example 2. A low-temperature preparation method of nanometer barium cerate powder is prepared according to the following steps:

[0030] A, take by weighing 0.015mol barium nitrate, 0.015mol cerium nitrate, 0.02mol glycerol and 0.03mol PVA respectively;

[0031] B. Add PVA to an appropriate amount of deionized water, and heat it at 95°C to dissolve it, and then prepare a 1.2mol / L PVA solution, add glycerin to it, and stir continuously to prepare an aqueous micellar liquid;

[0032] C. Add barium nitrate and cerium nitrate to the aqueous micellar liquid, and continuously stir the solution on a magnetic stirrer to become a viscous state to obtain a mixed solution;

[0033] D. Heating the mixed solution at 98°C to remove all water until it becomes a jelly-like substance to obtain a jelly-like substance;

[0034] E. Take out the jelly and place it in a pure aluminum oxide crucible, and calcinate it in a muffle furnace at 820°C for 8 hours without pressure. The jelly will ...

Embodiment 3

[0035] Example 3. A low-temperature preparation method of nanometer barium cerate powder is prepared according to the following steps:

[0036] A, take by weighing 0.02mol barium nitrate, 0.02mol cerium nitrate, 0.03mol glycerin and 0.06mol PVA respectively;

[0037] B. Add PVA to an appropriate amount of deionized water, and heat it at 98°C to dissolve it, and then prepare a 2mol / L PVA solution, add glycerin to it, and stir continuously to prepare an aqueous micellar liquid;

[0038] C. Add barium nitrate and cerium nitrate to the aqueous micellar liquid, and continuously stir the solution on a magnetic stirrer to become a viscous state to obtain a mixed solution;

[0039] D. Heating the mixed solution at 100°C to remove all water until it becomes a jelly-like substance to obtain a jelly-like substance;

[0040] E. Take out the jelly and place it in a pure aluminum oxide crucible, and calcinate it in a muffle furnace at 850°C for 10 hours without pressure. The jelly will re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com